Lithium cobalt oxide material and preparation method thereof, positive plate and lithium ion battery

A technology of lithium cobaltate and lithium niobate, which is applied in the fields of lithium ion batteries, lithium cobaltate materials and their preparation, and positive electrodes, can solve the problems of failure to form a stable and uniform coating layer, adverse cycle stability of lithium cobaltate, and coating In order to achieve the effect of maintaining structural stability and cycle stability, good ionic conductivity, and reducing material interface impedance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

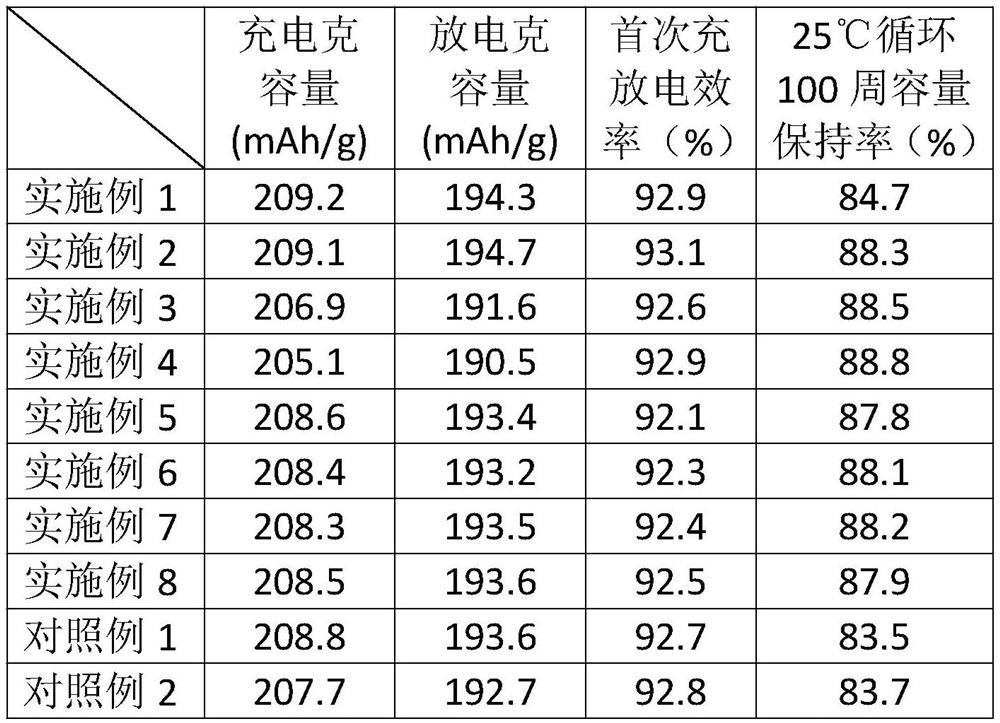

Examples

Embodiment 1

[0036] (1) Preparation of lithium cobaltate

[0037] Mix large particles of cobalt tetroxide and small particles of cobalt tetroxide at a ratio of 8:2, then add lithium carbonate with a ratio of Li and Co of 1.1:1, mix well, and calcinate at 850°C for 24 hours to prepare lithium cobaltate.

[0038](2) Preparation of lithium niobium oxide / cobalt tetroxide composite coating modified lithium cobalt oxide

[0039] Add 1 mol of lithium cobaltate to 1 L of anhydrous ethanol, and ultrasonically disperse it for 10 min to obtain a 1 mol / L lithium cobalt oxide / alcohol solution; then add 0.01 mol of niobium ethoxide and 0.012 mol of lithium ethoxide, and in N 2 Stir and reflux under protection for 20 hours to obtain lithium cobalt oxide coated with bimetallic organics, and then dropwise add 10 ml of deionized water for hydrolysis, and stir and heat the hydrolyzed gel until the solvent is completely volatilized to obtain lithium niobate-coated cobalt acid. The lithium material was finall...

Embodiment 2

[0050] The difference from Example 1 is: the preparation of lithium niobium oxide / cobalt tetroxide composite coating modified lithium cobaltate: the amount of niobium ethoxide added is 0.03 mol, and the added amount of lithium ethoxide is 0.036 mol.

[0051] The rest are the same as those in Embodiment 1, and are not repeated here.

Embodiment 3

[0053] The difference from Example 1 is: the preparation of lithium niobium oxide / cobalt tetroxide composite coating modified lithium cobalt oxide: the addition amount of niobium ethoxide is 0.05mol, and the addition amount of lithium ethoxide is 0.06mol.

[0054] The rest are the same as those in Embodiment 1, and are not repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com