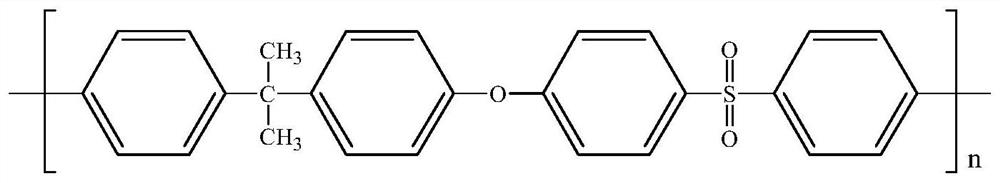

A kind of sulfonated dihydroxypropyl chitosan modified polysulfone membrane and preparation method thereof

A technology of sulfonated dihydroxypropyl chitosan and polysulfone membrane, which is applied in the field of biomedical materials, can solve the problems of poor molecular specificity of heparin, limit the clinical application of heparin-grafted polysulfone, and expensive heparin, and achieve mild reaction conditions Easy to control, maintain mechanical strength and structural stability, and improve hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

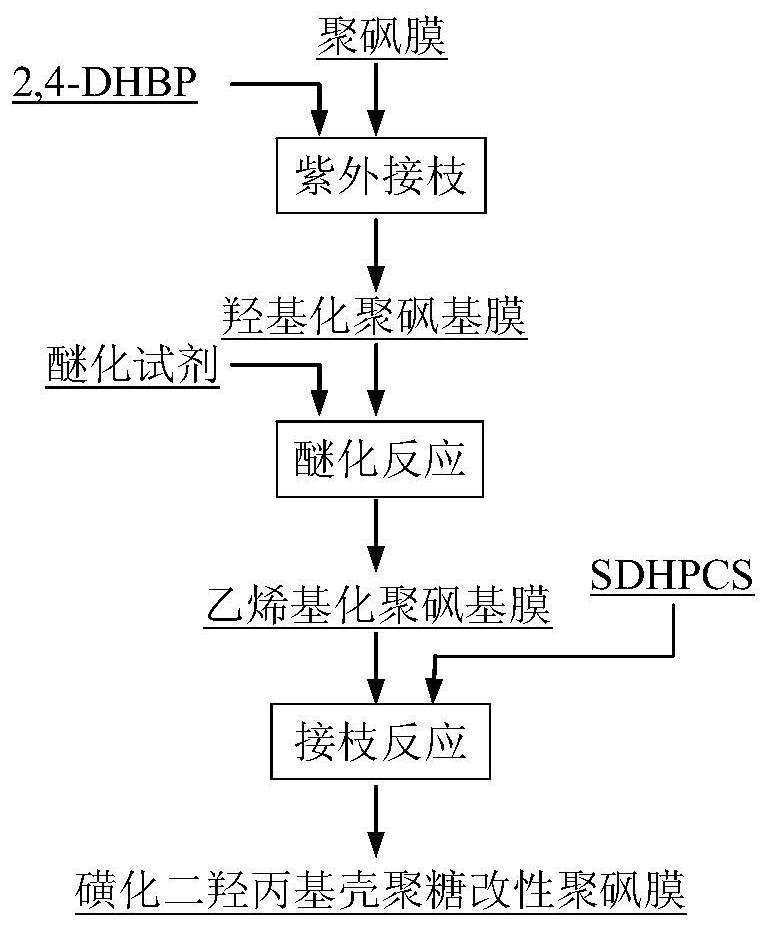

Method used

Image

Examples

Embodiment 1

[0043] Immerse the polysulfone-based membrane in 0.4moL / L 2,4-dihydroxybenzophenone methanol solution for 1h; take out the polysulfone-based membrane or leave it in the original solution, and irradiate it with a 160W UV lamp for 5min to obtain hydroxylation Polysulfone base membrane;

[0044] Add the hydroxylated polysulfone-based membrane to vinyl glycidyl ether, control the temperature at 50°C, and stir for 2 hours; after taking it out, wash it with absolute ethanol and deionized water, and then dry it under vacuum at 45°C to obtain ethylene Kylated polysulfone base membrane;

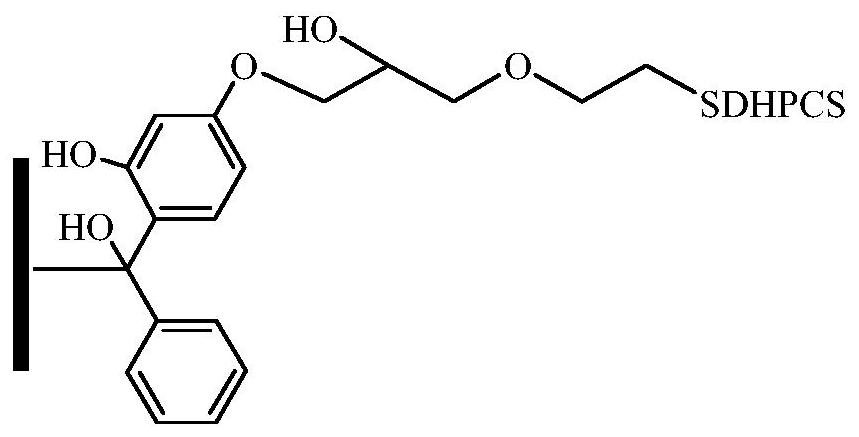

[0045] Add 1g of the SDHPCS obtained above into 45mL of deionized water, stir evenly, and make an SDHPCS aqueous solution; then add 5mL of potassium persulfate solution with a mass fraction of 5%, and then add the vinylated polysulfone-based membrane obtained above. Under the protection of nitrogen, stir and react at room temperature for 20 hours; after the reaction, wash the membrane with deionized ...

Embodiment 2

[0047] Immerse the polysulfone-based membrane in 0.4moL / L 2,4-dihydroxybenzophenone methanol solution for 40min; take out the polysulfone-based membrane or leave it in the original solution, and irradiate it with a 180W UV lamp for 5min to obtain hydroxylation Polysulfone base membrane;

[0048] Add the hydroxylated polysulfone-based membrane to vinyl glycidyl ether, control the temperature at 50°C, and stir for 2 hours; after taking it out, wash it with absolute ethanol and deionized water, and then dry it under vacuum at 45°C to obtain ethylene Kylated polysulfone base membrane;

[0049] Add 2 g of the SDHPCS obtained above into 45 mL of deionized water, stir evenly, and make an SDHPCS aqueous solution; then add 5 mL of potassium persulfate solution with a mass fraction of 5%, and then add the vinylated polysulfone-based membrane obtained above. Under the protection of nitrogen, stir and react at room temperature for 20 hours; after the reaction, wash the membrane with deio...

Embodiment 3

[0051] Immerse the polysulfone-based membrane in 0.4moL / L 2,4-dihydroxybenzophenone methanol solution for 1h; take out the polysulfone-based membrane or leave it in the original solution, and irradiate it with a 200W ultraviolet lamp for 10min to obtain hydroxylation Polysulfone base membrane;

[0052] Add the hydroxylated polysulfone-based membrane to vinyl glycidyl ether, control the temperature at 50°C, and stir for 2 hours; after taking it out, wash it with absolute ethanol and deionized water, and then dry it under vacuum at 45°C to obtain ethylene Kylated polysulfone base membrane;

[0053] Add 2 g of the SDHPCS obtained above into 45 mL of deionized water, stir evenly, and make an SDHPCS aqueous solution; then add 5 mL of potassium persulfate solution with a mass fraction of 5%, and then add the vinylated polysulfone-based membrane obtained above. Under the protection of nitrogen, stir and react at room temperature for 20 hours; after the reaction, wash the membrane wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com