Lithium ion battery

A lithium-ion battery, carbon atom technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as cycle performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0157] This embodiment is used to illustrate the lithium ion battery disclosed in the present invention and the preparation method thereof, including the following operation steps:

[0158] 1) Preparation of positive electrode sheet

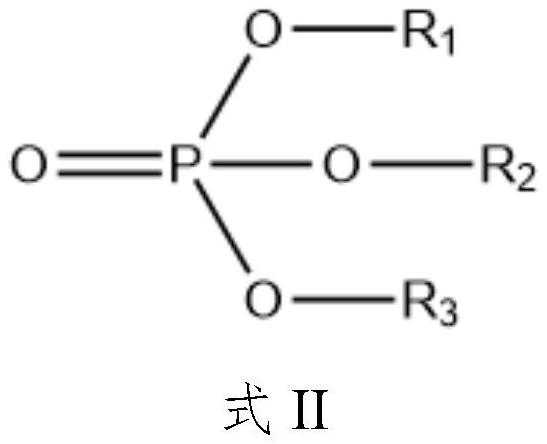

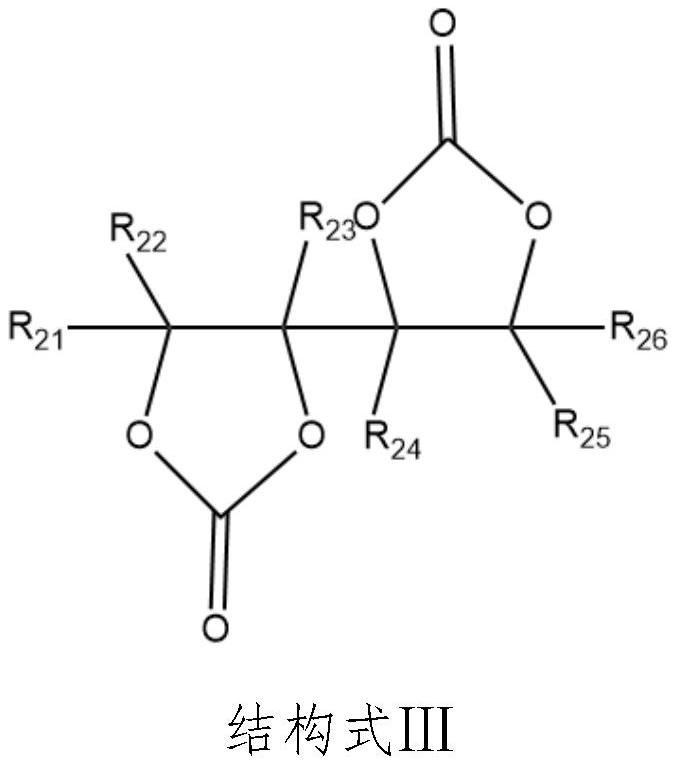

[0159] Step 1: In the NMP solvent, add PVDF as a binder and the compound represented by the formula II shown in Table 2, and stir well to obtain a PVDF glue solution added with the compound represented by the formula II.

[0160] Step 2: Add the conductive agent (super P+CNT) to the PVDF glue solution and stir well.

[0161] Step 3: Continue to add the positive electrode active materials shown in Table 2, stir well, and finally obtain the required positive electrode slurry.

[0162] Step 4: uniformly coat the prepared positive electrode slurry on a positive electrode current collector (eg, aluminum foil), and obtain a positive electrode sheet by drying, rolling, die-cutting or slitting.

[0163] 2) Preparation of negative electrode sheet

[01...

Embodiment 2~26

[0176] Examples 2 to 26 are used to illustrate the lithium ion battery disclosed in the present invention and the preparation method thereof, including most of the operation steps in Example 1, and the differences are:

[0177] The positive electrode sheet components and electrolyte addition components shown in Table 2 were used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com