Sample box for glow discharge analysis and characterization and use method

A technology of glow discharge and sample box, which is used in electrical excitation analysis, material analysis by optical means, and material analysis, etc. The effect of resolution improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

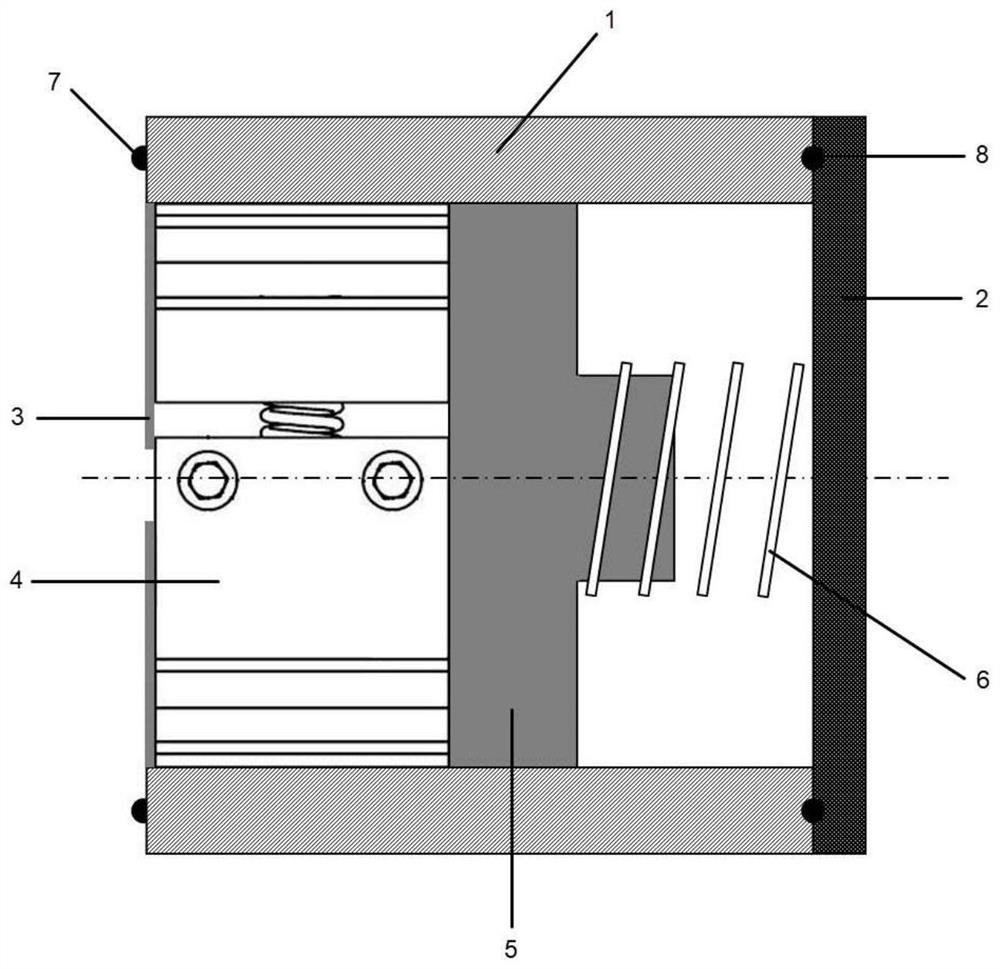

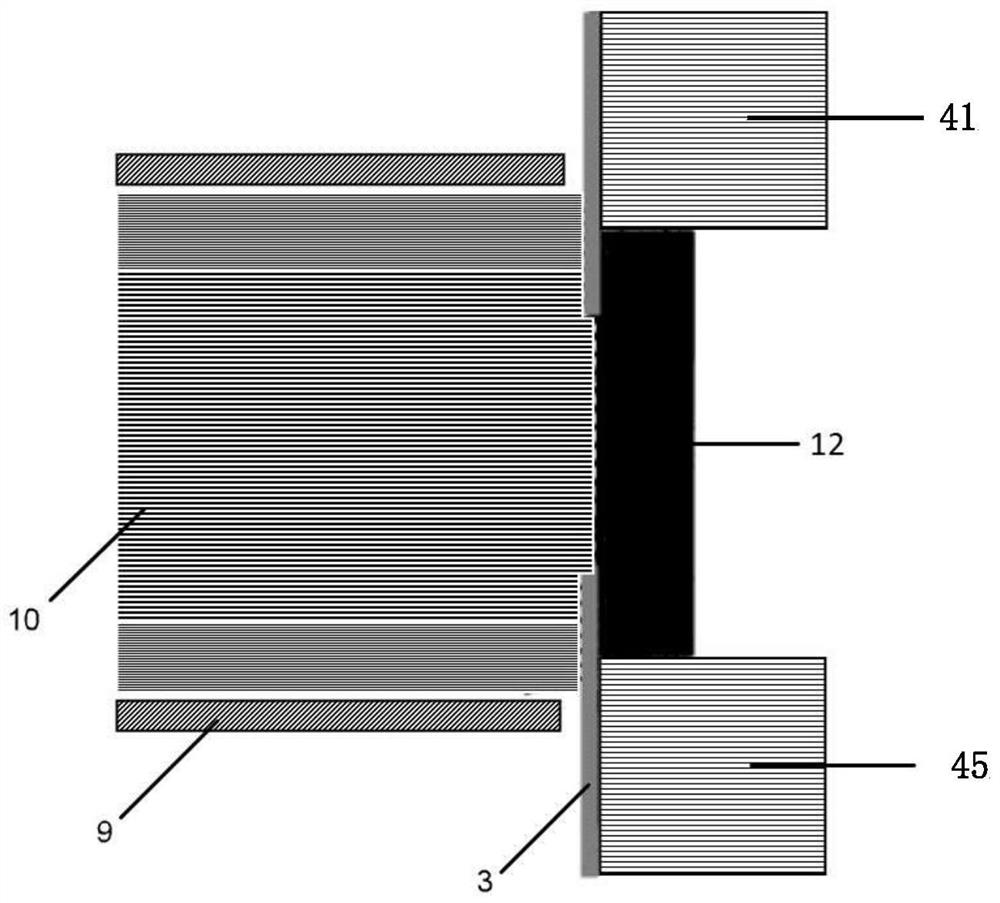

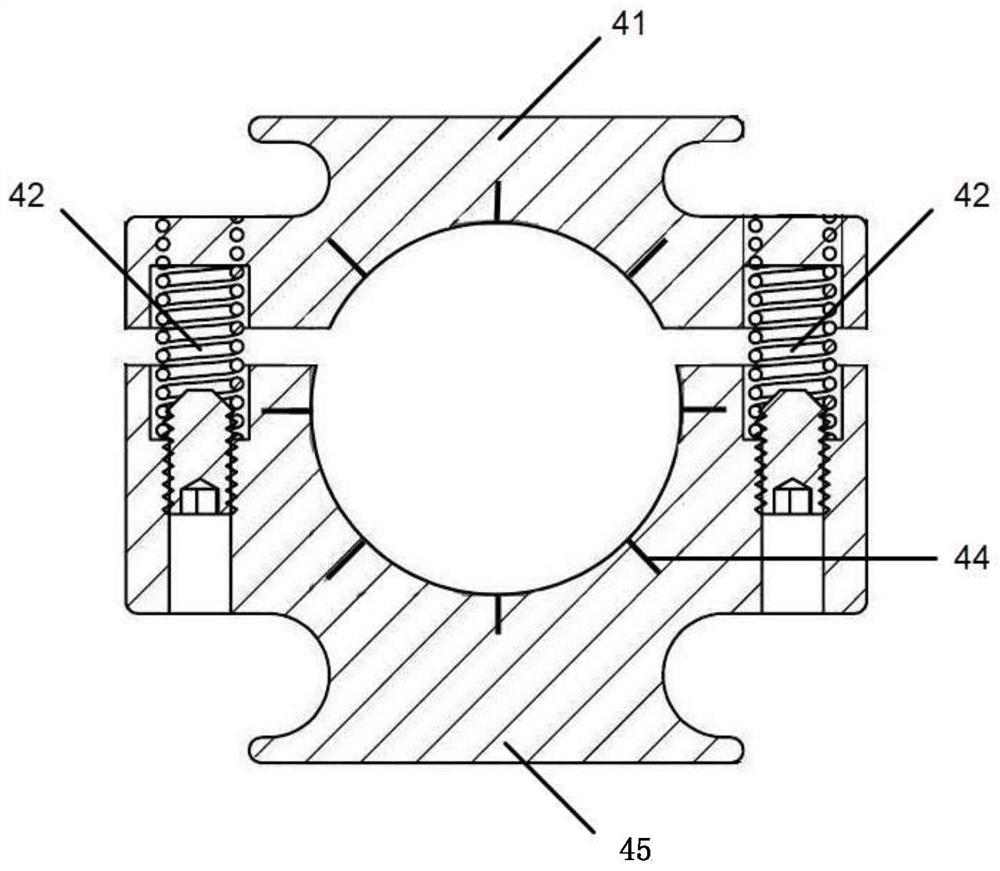

Method used

Image

Examples

Embodiment 1

[0090] Using the method of using the sample box for glow discharge analysis and characterization, multiple glow discharge analysis and characterizations are performed on the nickel-based single crystal superalloy sample at the same position. The operation steps are as follows:

[0091] S1. Precisely position the nickel-based single crystal superalloy sample according to the size of the sample holding hole of the fixture 4 and the size of the sample box, and cut and process it into a suitable size and shape, such as processing it into a cylinder with a diameter of 30 mm and a thickness of 30 mm. Ultrasonic cleaning is performed on the surface of the sample to remove oil and impurities brought about by the processing. Use a sample grinding machine to process the side of the sample to be analyzed to obtain a flat and clean surface; it is recommended to use a sandpaper of 600 mesh or more for the sample grinding, and the sample surface can also be polished. A smoother sample surfa...

Embodiment 2

[0097] Using the method of using the sample box for glow discharge analysis and characterization, the glow discharge depth profile analysis is carried out on the galvanized sheet sample. The operation steps are as follows:

[0098] S1. Precisely position the galvanized sheet sample according to the size of the sample holding hole of the jig 4, cut and process it into a suitable size and shape, for example, process it into a sheet with a diameter of 30 mm. Ultrasonic cleaning is performed on the surface of the sample to remove oil and impurities brought about by the processing. When the thin slice sample is too thin, the thin slice sample can be glued together with the thickened cylindrical sample with conductive double-sided adhesive tape, and the sample analysis surface needs to be exposed outside. On the back side of the thickened sample (non-analytical surface), several corresponding marking points are prepared for accurate positioning of the sample in the sample precise p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com