Preparation method of HRB500E coiled steel

A HRB500E, coiled screw technology, applied in the field of HRB500E coiled steel preparation, can solve the problems of increasing the amount of microalloys added, large fluctuations, reduced tensile strength Rom, etc., to reduce hardenability, enhance stability, and avoid grains. coarse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

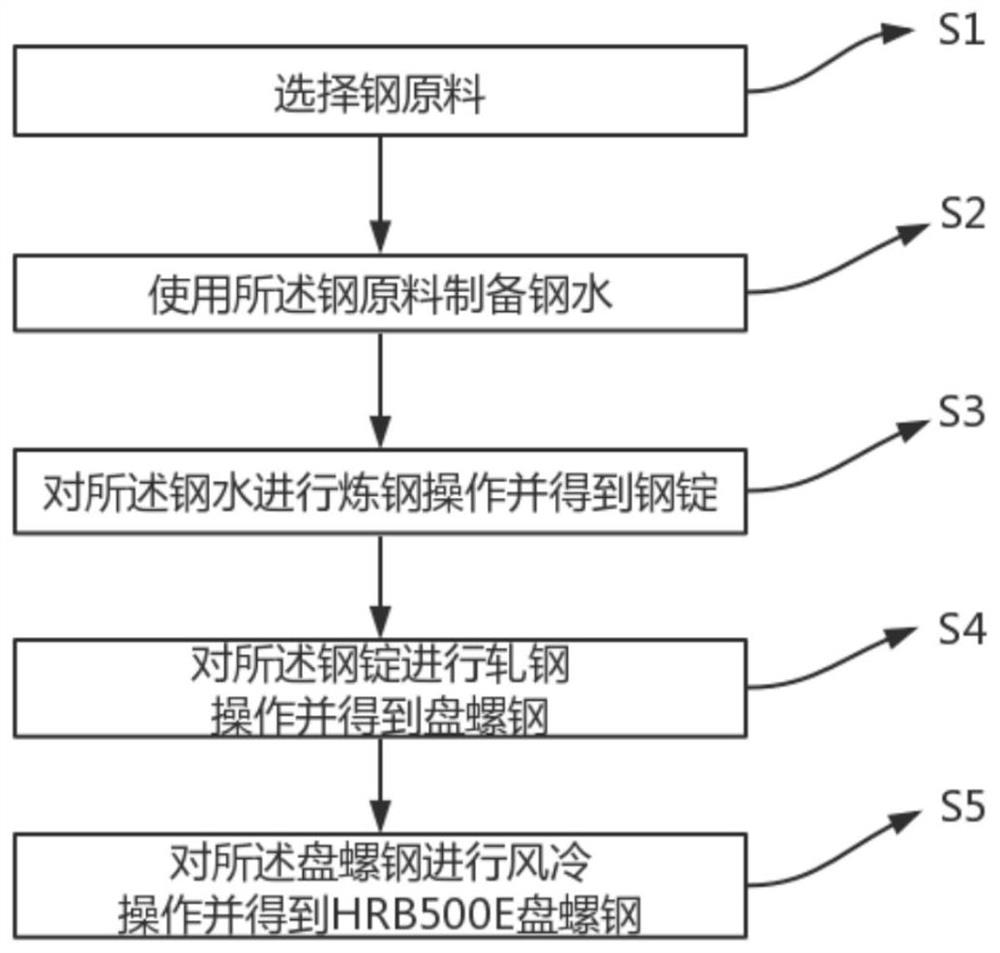

[0046] Such as figure 1 , in the embodiment of the present application, the present invention provides a method for preparing HRB500E disc screw steel, the method includes the steps of:

[0047] S1: Select steel raw material;

[0048] S2: using the steel raw material to prepare molten steel;

[0049] S3: performing a steelmaking operation on the molten steel to obtain a steel ingot;

[0050] S4: Carrying out rolling operation on the steel ingot to obtain coil steel;

[0051] S5: Air-cooling the coiled steel to obtain HRB500E coiled steel.

[0052] In the embodiment of the present application, the chemical composition and mass percentage of the steel raw material in step S1 are: C: 0.22%-0.25%, Si: 0.50%-0.65%, Mn: 1.25%-1.35%, V: 0.065%- 0.075%, the balance is Fe and unavoidable impurities.

[0053] In the embodiment of the present application, the advantage of selecting the steel raw material according to the above chemical composition and mass percentage is that it can ...

Embodiment 1

[0093] The chemical composition and mass percentage of steel raw material of HRB500E coiled steel are:

[0094] Composition 1: C: 0.25%, Si: 0.65%, Mn: 1.35%, V: 0.075%, the balance is Fe and unavoidable impurities;

[0095] Composition 2: C: 0.23%, Si: 0.56%, Mn: 1.30%, V: 0.070%, the balance is Fe and unavoidable impurities;

[0096] Composition 3: C: 0.22%, Si: 0.50%, Mn: 1.25%, V: 0.065%, the balance is Fe and unavoidable impurities;

[0097] The production process of the HRB500E plate screw steel is as follows:

[0098] Molten iron→converter smelting→adding alloys→refining→continuous casting into billets→heating in heating furnace→controlled rolling→controlled cooling.

[0099] The steelmaking process and control are as follows: alloy is added at the end of the converter, continuous casting adopts full protection pouring, and the superheat does not exceed 35°C.

[0100] Steel rolling process and control are:

[0101] The rolling process is controlled by the following ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com