Method for synthesizing protein skeleton nano-material and application of protein skeleton nano-material in immobilized enzyme

A technology of nanomaterials and immobilized enzymes, applied in the direction of immobilization on/in organic carriers, nanotechnology, nanotechnology, etc., can solve problems such as inhibition, and achieve low cost, convenient product separation and detection, and low price effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for synthesizing protein skeleton nanomaterials, comprising the following steps:

[0037] Step 1. At room temperature, take 1 mL of 60 mg / mL egg white solution, add 6 mL of DMSO at 200 rpm, and finally add 4 mL of 50 mmol / L, pH=7, Tris-HCl buffer solution to form a white precipitate Finally, increase the rotation speed to 400 rpm and react for 30 minutes. After the reaction is completed, the reaction system is placed at 4°C for 12 hours to obtain a white suspension, and the Tris-HCl buffer solution acts to initiate the reaction;

[0038] Step 2, centrifuge the white suspension at a speed gradient of 6000 rpm for 10 min, discard the supernatant, wash with an equal volume of water for 3 times, and centrifuge at 4000-8000 rpm for 5 min each time to obtain the protein Skeleton nanomaterials are difficult to wash if the speed is too high.

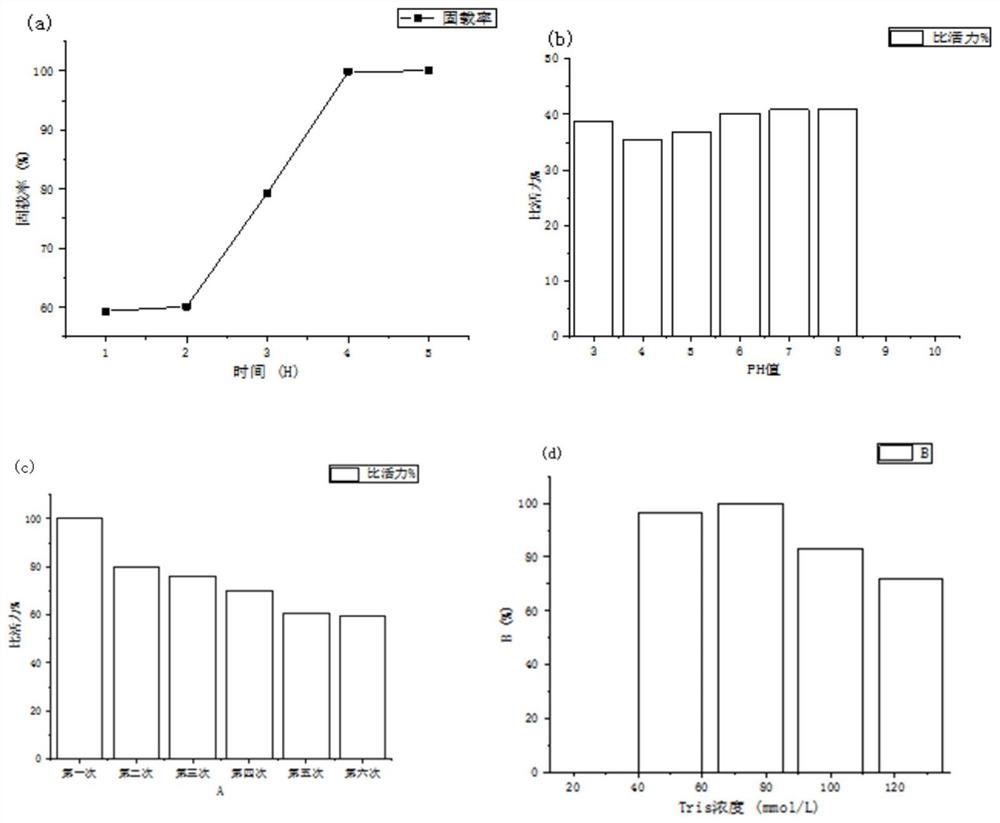

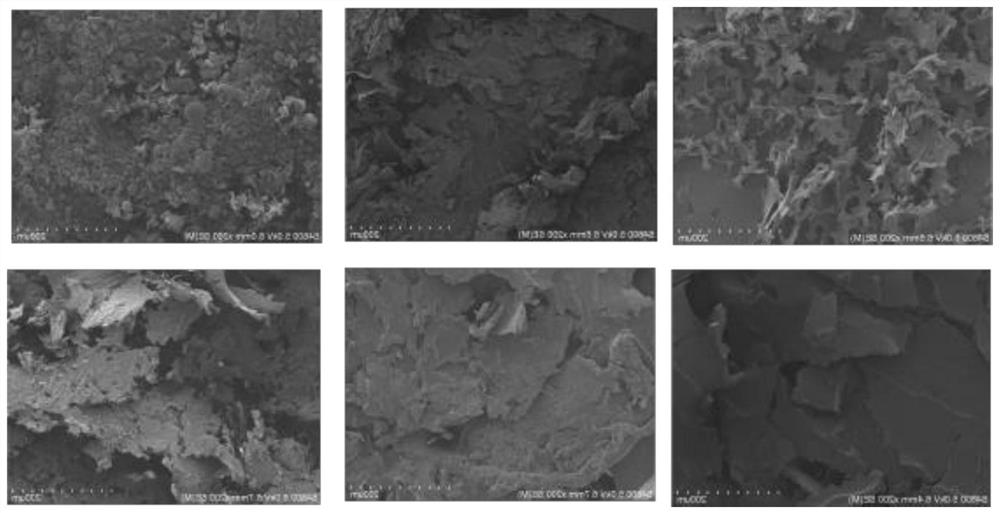

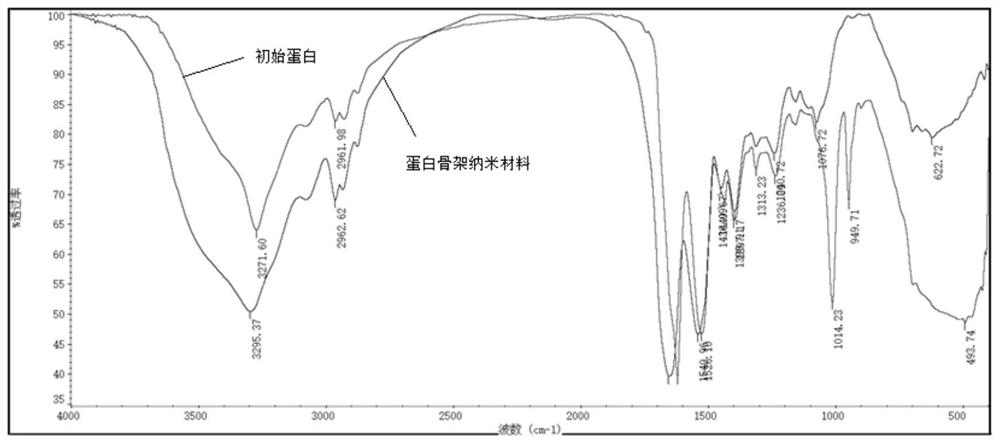

[0039] During the preparation process, by adding the tris buffer for 0-30 min, the protein skeleton nanomaterials were charact...

Embodiment 2

[0048] In order to compare the influence of different concentrations of Tris-HCl buffer solution on the material formation, the concentration of Tris-HCl buffer solution in step 1 is set to 25 mmol / L, 50 mmol / L, 75 mmol / L, 100 mmol / L, 125 mmol / L, other conditions are with embodiment 1.

[0049] From the experimental results, it can be seen that when the concentration of Tris-HCl buffer solution is too low, it cannot be formed smoothly. Although the amount of prepared material increases at high concentration, a large part of the material is no-load material, and the concentration is too high. Intrinsically active, when the concentration is 50 mmol / L-75 mmol / L, the synthesis of protein-skeleton nanomaterials is more stable, and when the Tris-HCl buffer solution is 50 mmol / L, the performance of protein-skeleton nanomaterials is more excellent, The result is as figure 1 (d) shown.

Embodiment 3

[0051] In Example 1, "after the reaction was completed, the reaction system was left to stand at 4°C for 12 h", the rest were the same as in Example 1.

[0052] We will find that the protein skeleton nanomaterial prepared in Example 3 is unstable in the aqueous phase and will decompose by itself. Methanol is often used for preservation, but after methanol preservation, the enzyme activity of the immobilized enzyme after application will be reduced.

[0053] Example 1 of the present invention used in the synthesis process to use the original system after standing for 12 h. The Coomassie Brilliant Blue method was used to measure the protein content of the solution after washing. The protein content in the material loss rate supernatant was 0.05 mg / ml. At the same time, the protein concentration of the total system before synthesis is 5.5 mg / ml, and the loss rate is less than 1%. Therefore, the synthesis method of the present invention can ensure that the material is stable, not ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com