Bran processing equipment adopting steam explosion technology

A technology for processing equipment and bran, which is applied in the field of bran processing equipment in a steam explosion process, can solve the problems that bran is not easily ground into fine particles, the dense structure is difficult to break, the bran pulverization performance is poor, and the processing performance is poor, so as to improve the processing performance. performance and pulverizing performance, the effect of improving utilization, improving pulverizing performance and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

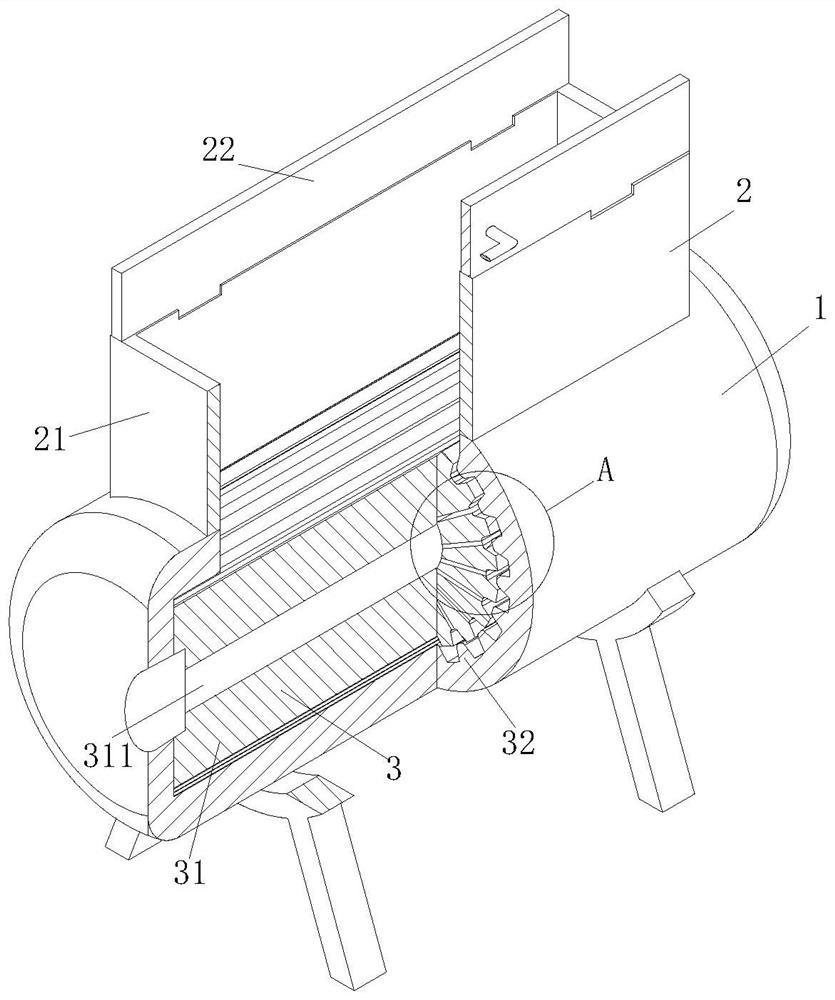

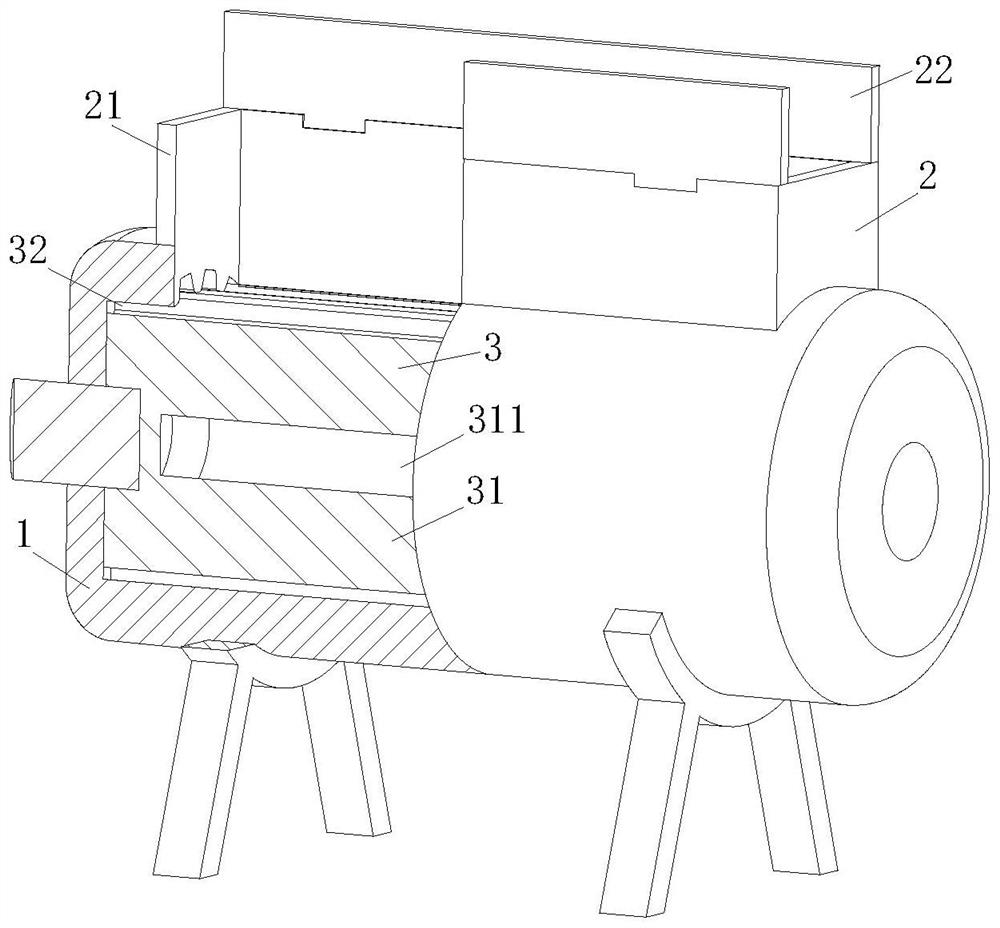

[0038] A kind of steam explosion technique bran processing equipment of the present invention, such as Figure 1-3 As shown, it includes a barrel body 1 and a support module that supports the barrel body 1, and also includes:

[0039] Feeding module 2, described feeding module 2 is installed on the staving 1, and feeding module 2 is used for adding the bran to be processed in staving 1;

[0040] A discharge module, the discharge module corresponds to the feed module 2 and is installed on the barrel body 1, and the discharge module is used to output the processed bran to the barrel body 1;

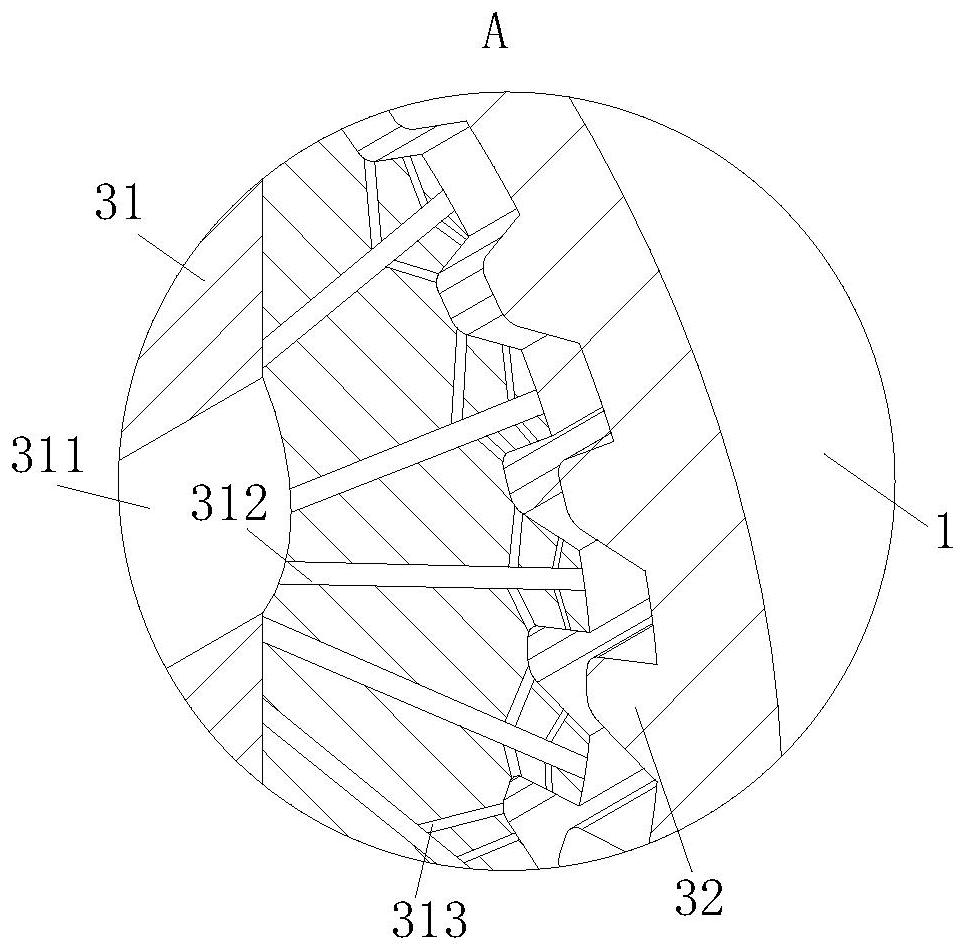

[0041] A processing module, the processing module includes a crushing unit 3 that is crushed by the cooperation of the crushing roller 31 and the crushing ring 32 and installed inside the barrel body 1;

[0042] The crushing ring 32 is installed on the inner wall of the barrel body 1, and the position corresponding to the crushing ring 32 and the feed module 2 is provided with a gap, so that...

Embodiment 2

[0047] A kind of steam explosion technique bran processing equipment of the present invention, such as Figure 1-3 As shown, it includes a barrel body 1 and a support module that supports the barrel body 1, and also includes:

[0048] Feeding module 2, described feeding module 2 is installed on the staving 1, and feeding module 2 is used for adding the bran to be processed in staving 1;

[0049] A discharge module, the discharge module corresponds to the feed module 2 and is installed on the barrel body 1, and the discharge module is used to output the processed bran to the barrel body 1;

[0050] A processing module, the processing module includes a steam explosion unit for supplying steam into the barrel body 1 .

[0051] In the prior art, lye is usually used to promote the dissolution of pentosan in wheat bran, but the alkali method has serious pollution and has adverse effects such as destruction of proteins, polyphenols and other substances; or, conventional crushing equ...

Embodiment 3

[0055] A kind of steam explosion technique bran processing equipment of the present invention, such as Figure 1-3 As shown, it includes a barrel body 1 and a support module that supports the barrel body 1, and also includes:

[0056] Feeding module 2, described feeding module 2 is installed on the staving 1, and feeding module 2 is used for adding the bran to be processed in staving 1;

[0057] A discharge module, the discharge module corresponds to the feed module 2 and is installed on the barrel body 1, and the discharge module is used to output the processed bran to the barrel body 1;

[0058] A processing module, the processing module includes a steam explosion unit that provides steam into the barrel body 1 and a crushing unit 3 that is crushed by the cooperation of the crushing roller 31 and the crushing ring 32 and installed inside the barrel body 1;

[0059] The crushing ring 32 is installed on the inner wall of the barrel body 1, and the position corresponding to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com