Deep-hole groove-broaching top-breaking gangue-returning-free charging structure and operation method thereof

A technology of deep hole pulling and top breaking, applied in blasting and other directions, can solve the problems of blasting work, crushing the barrel, blocking the blast hole, etc., and achieves the effect of effectively reducing the amount of explosives and reducing the phenomenon of backlash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

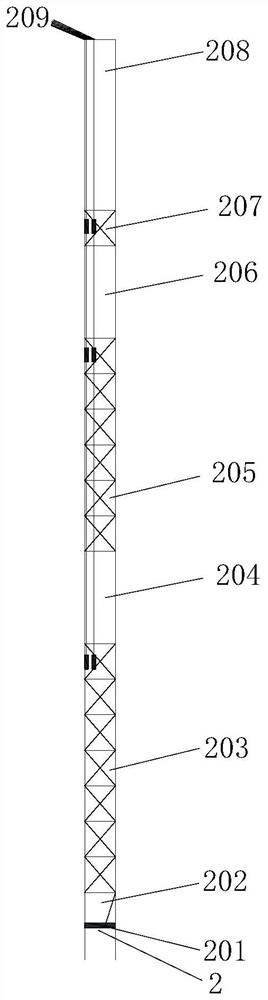

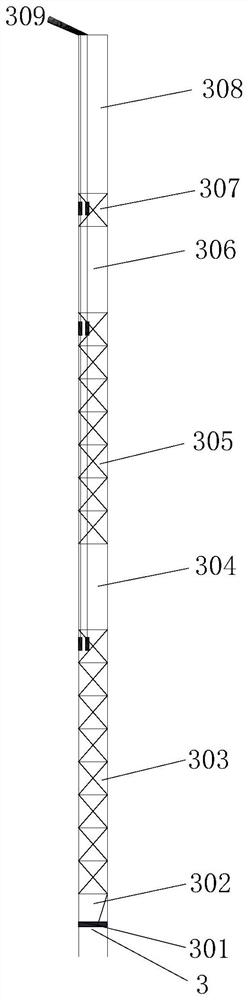

[0024] see Figure 1-4 : a kind of deep-hole slotting of the present embodiment breaks the roof and avoids returning gangue charge structure, including some blastholes distributed in the groove area of the roof breaking area, and some of the blastholes are distributed in circles from the inside to the outside, and on each circle layer The blastholes are evenly distributed, the blastholes on the outermost ring layer are equipped with corresponding blasting components, and the blastholes on the inner ring layer are equipped with corresponding blasting components or blanks, and the blastholes are empty. Used as free surface and air outlet.

[0025] The blastholes in this embodiment are distributed in several circles. By leaving several blastholes as free surfaces and air outlets, it can effectively reduce the backflush phenomenon caused by excessive concentration of explosives, and avoid the blasting work carried out later after the blasting zone of the front hole is damaged. ...

Embodiment 2

[0041] This embodiment also discloses an operation method for breaking the roof of the deep-hole pull groove and avoiding the return of the gangue charge structure. The order is: the bottom layer 0ms millisecond delay detonator 1 stage two shots in the first circle, the second floor 75ms millisecond delay detonator 4 stage two shots, the third circle 150 / 200ms millisecond delay detonator 6 / 7 stage two shots, the second The middle layer of the 310ms millisecond delay detonator in the first circle has two shots at the 9th stage, the second lap has the middle layer of the 380ms millisecond delay detonator and the 10th stage has two shots, the third lap has the middle layer of the 460 / 550ms millisecond delay detonator and the 11th / 12th stage has two shots, and the upper layer of the first circle The 650ms millisecond delay detonator has two shots at the 13th stage, the middle 760ms millisecond delay detonator has two shots at the 14th stage, and the third lap has the upper 880ms mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com