Waterproof structure of box culvert deformation joint

A technology of waterproof structure and deformation joints, which is applied in the field of deformation joints, can solve problems such as leakage in box culverts, reduce the probability of leakage, and enhance the effect of anti-seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

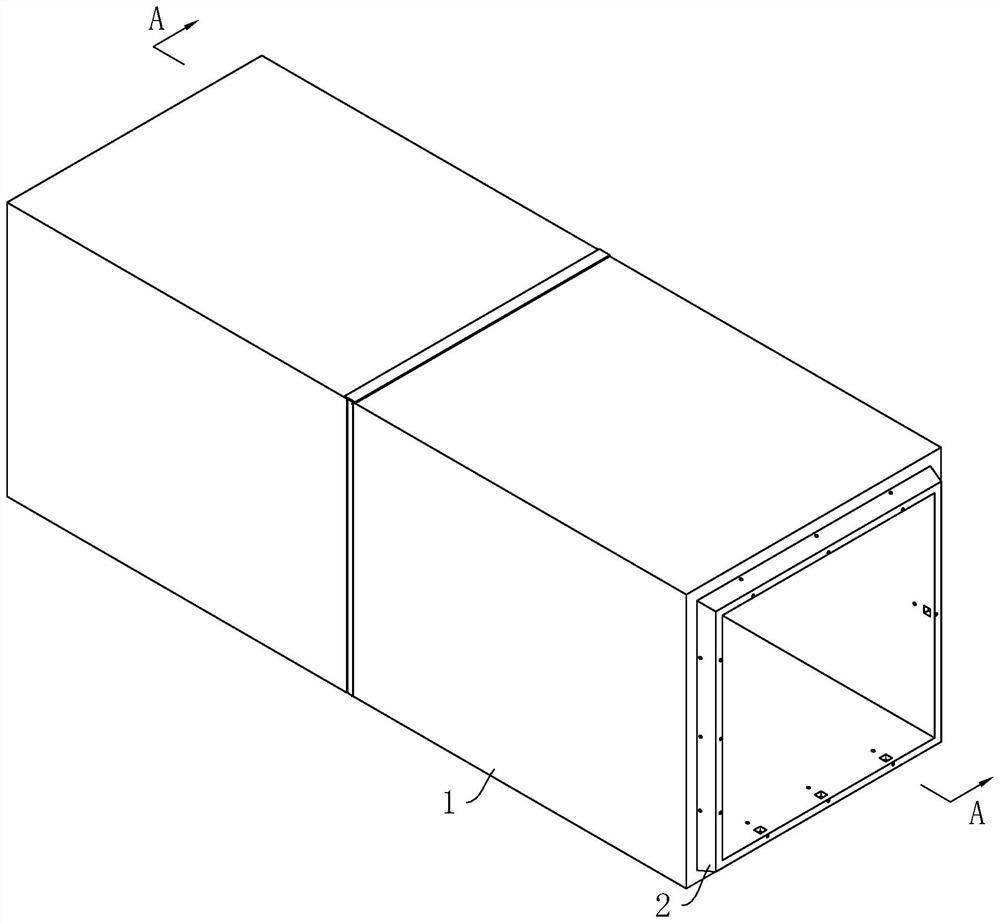

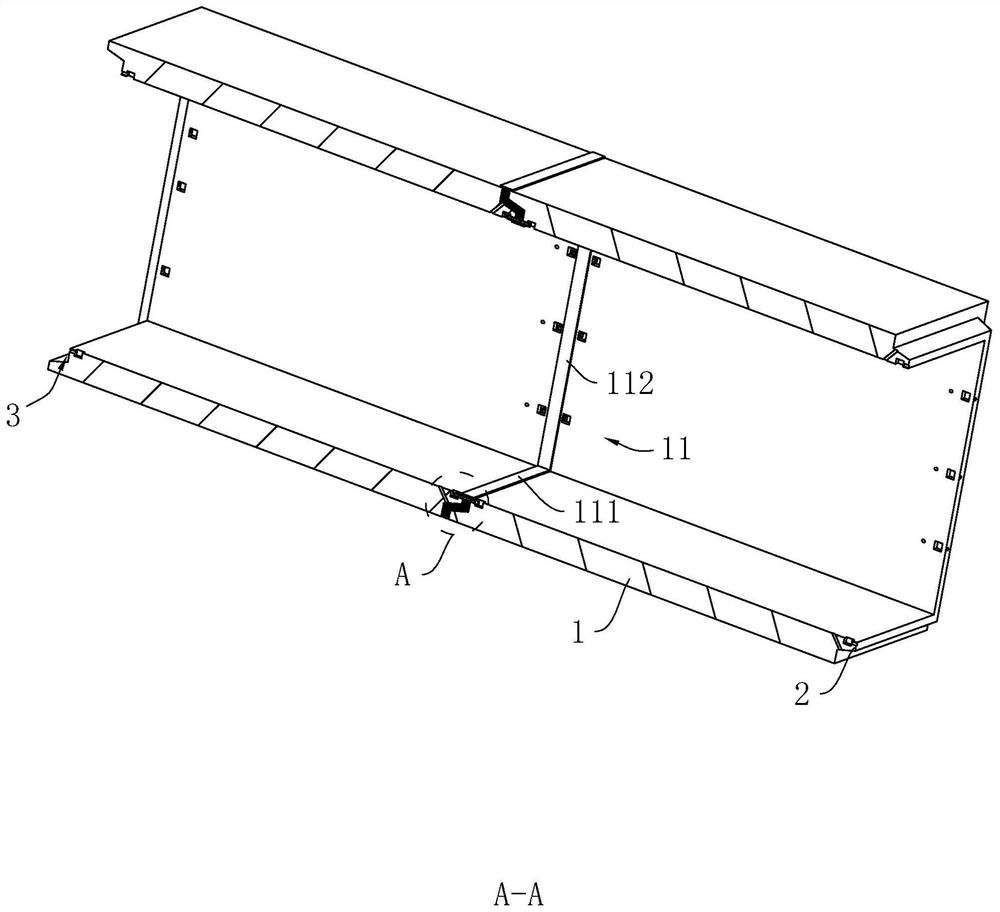

[0043] refer to figure 1 , the waterproof structure of the deformation joint of the box culvert includes several box culverts 1. In this embodiment, the number of box culverts 1 is two as an example, and one side end wall of one box culvert 1 is provided with a box for extending into another box culvert. The positioning ring block 2 in 1, the positioning ring block 2 is integrally formed with the box culvert 1, and the other side end wall of the box culvert 1 is provided with a positioning ring groove 3 matching with the positioning ring block 2, and the positioning ring groove 3 It is connected with the port of box culvert 1. During construction, the two box culverts 1 are docked by means of oil cylinder jacking, until the positioning ring block 2 is inserted into the positioning ring groove 3, so as to realize the butt joint assembly between the two box culverts 1 .

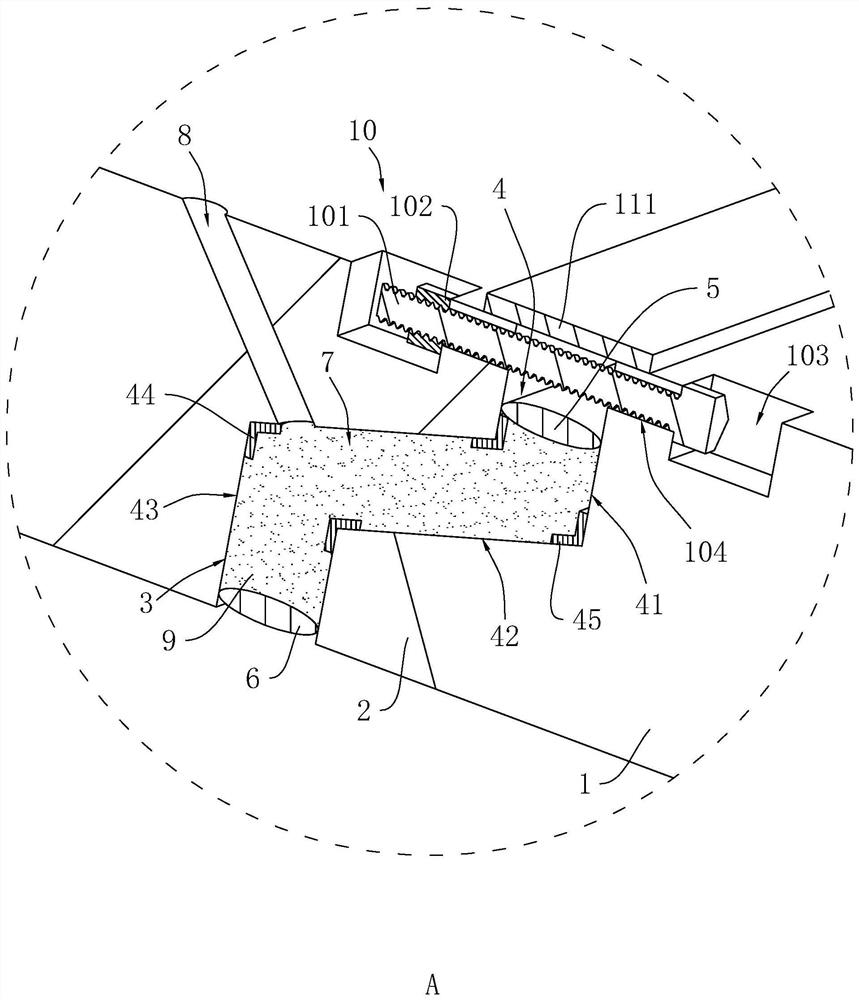

[0044] refer to figure 2 with image 3 , in this embodiment, the outer ring wall of the positioning ring...

Embodiment 2

[0053] refer to Figure 4 with Figure 5 The difference between the embodiment of the present application and embodiment 1 lies in the structure of the connection assembly 10 .

[0054] refer to Image 6 with Figure 7 , the connecting assembly 10 includes two connecting plates 12, the length of the connecting plates 12 is consistent with the length or width or height of the box culvert 1, the connecting plate 12 in the present embodiment is made of waterproof material, and two adjacent box culverts 1 Connection grooves 13 are provided on the inner side walls of the two connection grooves 13, and the two connection plates 12 correspond to the two connection grooves 13 respectively. The connecting port 14 connected to the space 4, one side of the connecting plate 12 passes through the connecting port 14 and extends into the impermeable space 4, the two connecting plates 12 are arranged opposite each other, and one of the connecting plates 12 is located on the end wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com