A kind of industrial water-based paint coating and using method thereof

A water-based paint and coating technology, applied in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as pollution and discharge, and achieve the effect of ensuring anti-corrosion and anti-rust, taking into account the appearance effect, and the best anti-rust effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

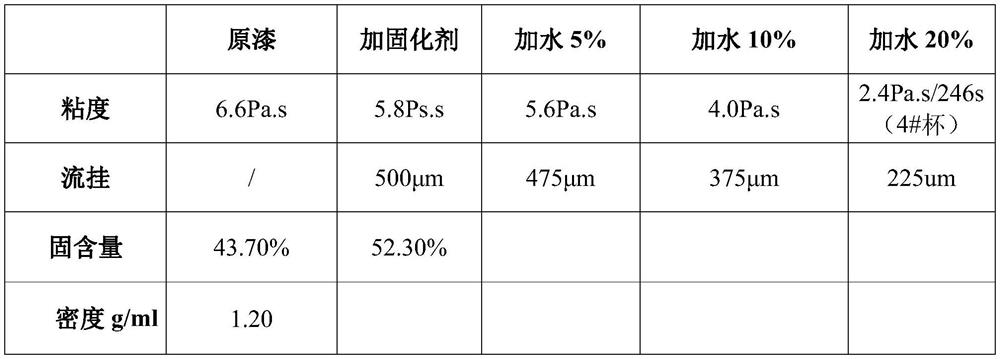

[0018] The water-based epoxy primer of the present invention uses water as a dispersing medium, and is used after mixing the A component and the B component in a mass ratio of 7.5-9:1, thereby cross-linking and curing to form a film. Component B is a non-ionic, aqueous secondary dispersion curing agent for polyamide adducts.

[0019] The raw materials used in component A include: in parts by weight, waterborne epoxy resin 30-40, deionized water 10-30, dispersant 1-2, defoamer 0.1-0.3, filler 35-45, acrylic resin 3-10. Wetting and leveling agent 0.1-0.5, surfactant 0.1-0.5, low shear thickener 0.3-0.6 and medium shear thickener 0.1-0.3.

[0020] As a preference of the present invention, the water-based epoxy resin is a secondary dispersion of solid bisphenol A epoxy resin modified by solid 901 epoxy resin. The dispersing agent is polyacrylate, and the defoaming agent is a non-silicon polymerized defoaming agent or an acetylene glycol defoaming agent. The low shear thickener i...

Embodiment 2

[0027] The water-based aliphatic polyurethane topcoat of the present invention uses water as a dispersion medium, and the primary and secondary dispersions of hydroxyacrylic acid are mixed, cross-linked and cured with the water-based aliphatic isocyanate curing agent at a ratio of 5-7:1 to form a paint film.

[0028] The components of the water-based aliphatic polyurethane topcoat include: in parts by weight, 10-20 hydroxy acrylic primary dispersion resin, 40-50 hydroxy acrylic secondary dispersion resin, 10-30 deionized water, polyacrylate dispersant 1-2, non-silicon polymeric defoamer 0.1-0.3, filler 15-25, wetting and leveling agent 0.1-0.5, surfactant 0.1-0.5, polyurethane low shear thickener 0.2-0.5; polyurethane Medium shear thickener 0.1-0.3.

[0029] As a preference of the present invention, the water-based aliphatic polyurethane topcoat further includes 0.1-0.5 of a metal catalyst and 0.5-1 of a modified composite inorganic anti-settling thixotropic agent. The metal ...

Embodiment 3

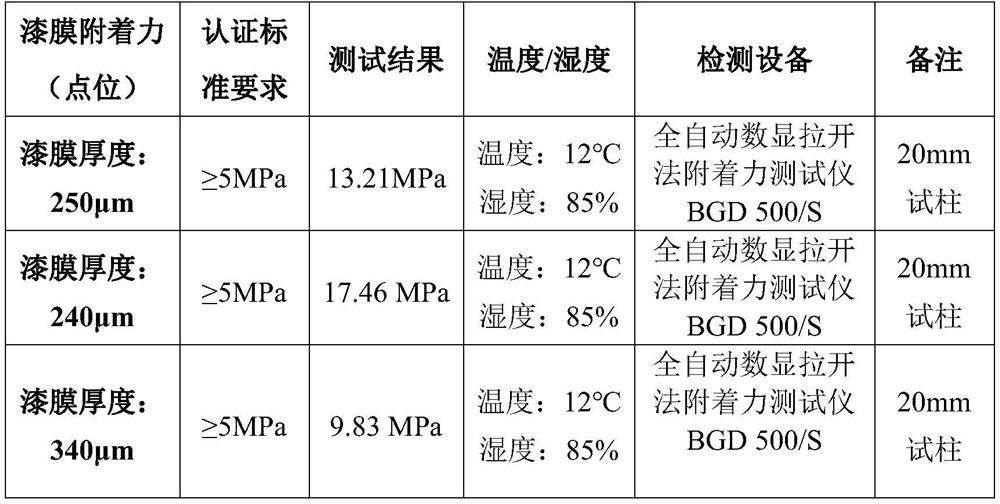

[0033] According to the components and methods in Example 1 and Example 2, waterborne epoxy primer and waterborne aliphatic polyurethane topcoat were prepared respectively.

[0034] Waterborne epoxy primer: waterborne epoxy resin 38, deionized water 15, dispersant 1.5, defoamer 0.2, filler 38, acrylic resin 8, wetting and leveling agent 0.3, surfactant 0.3, metal catalyst 0.1, Rust agent 2, low shear thickener 0.5 and medium shear thickener 0.2.

[0035]Waterborne aliphatic polyurethane topcoat: hydroxyacrylic secondary dispersion resin 50, deionized water 10, polyacrylate dispersant 2, non-silicon polymeric defoamer 0.3, filler 20, hydroxyacrylic primary dispersion resin 18, Wetting and leveling agent 0.1-0.5, surfactant 0.5, metal catalyst 0.3, modified composite inorganic anti-settling thixotropic agent 1, polyurethane low shear thickener 0.2 and polyurethane medium shear thickener 0.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com