Moisture-absorbing quick-drying fabric and preparation method thereof

A moisture-absorbing and quick-drying fabric technology, applied in the textile field, can solve problems such as the adverse effects of evaporation rate, achieve the effect of retaining hydrophilic moisture permeability, enhancing hygroscopicity and quick-drying, and enhancing wearability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

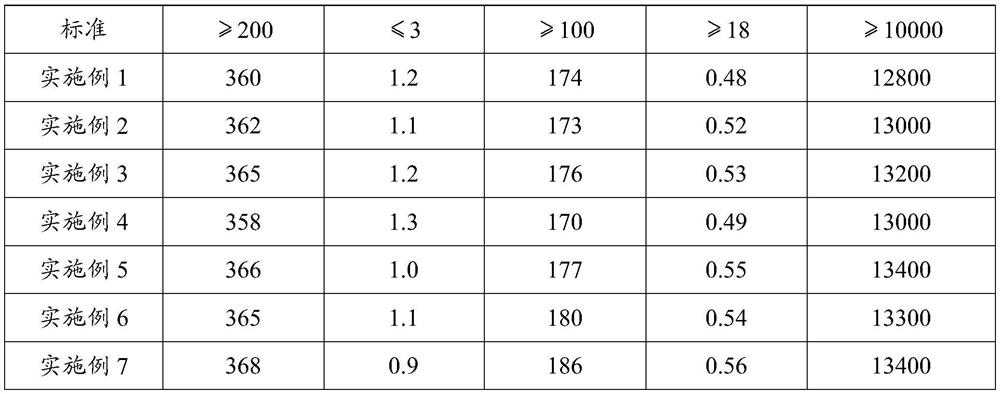

Embodiment 1

[0026] A moisture-absorbing and quick-drying fabric, the fabric includes a hydrophilic inner layer and a quick-drying outer layer, the hydrophilic inner layer is composed of a bottom yarn, the quick-drying outer layer is composed of a veil, and the bottom yarn is combed cotton yarn , the veil is a Y-type superfine denier polyester filament, the yarn fineness of the bottom yarn is 7.5tex, and the F number is 64, and the specification of the veil is 20D, 160F; the preparation method of the fabric is: The base yarn and the veil are woven with a mass ratio of 1:2 and a grammage of 140g / m 2 The weft-knitted double-sided knitted plain gray fabric is obtained through fabric finishing to obtain the moisture-absorbing and quick-drying fabric; the fabric finishing includes alkali treatment and softening treatment, and the alkali treatment condition is: using 1wt.% sodium hydroxide solution , Liquor ratio 1:50, treatment at 90°C for 30min; the softening condition is: using silicone-free ...

Embodiment 2

[0028] A moisture-absorbing and quick-drying fabric, the fabric includes a hydrophilic inner layer and a quick-drying outer layer, the hydrophilic inner layer is composed of a bottom yarn, the quick-drying outer layer is composed of a veil, and the bottom yarn is combed cotton yarn , the veil is a Y-type superfine denier polyester filament, the yarn fineness of the bottom yarn is 9.5tex, and the F number is 78, and the specification of the veil is 25D, 230F; the preparation method of the fabric is: The ground yarn and the veil are woven with a mass ratio of 1:3 and a grammage of 140g / m 2 Weft-knitted double-sided knitted plain gray fabric, and then through fabric finishing to obtain the moisture-absorbing and quick-drying fabric; the fabric finishing includes alkali treatment and softening treatment, and the alkali treatment condition is: using 1.5wt.% sodium hydroxide Solution, bath ratio 1:50, treated at 95°C for 30min; the softening condition is: use silicone-free softening...

Embodiment 3

[0030] A moisture-absorbing and quick-drying fabric, the fabric includes a hydrophilic inner layer and a quick-drying outer layer, the hydrophilic inner layer is composed of a bottom yarn, the quick-drying outer layer is composed of a veil, and the bottom yarn is combed cotton yarn , the veil is a hollow section superfine denier polyester filament, the yarn fineness of the ground yarn is 11.5tex, the F number is 70, and the specification of the veil is 25D, 110F; the preparation method of the fabric is: The base yarn and the veil are woven with a mass ratio of 1:3 and a grammage of 150g / m 2 Weft-knitted double-sided knitted plain gray fabric, and then through fabric finishing to obtain the moisture-absorbing and quick-drying fabric; the fabric finishing includes alkali treatment and softening treatment, and the alkali treatment condition is: using 2.0wt.% sodium hydroxide Solution, bath ratio 1:50, treated at 95°C for 40min; the softening condition is: using silicone-free soft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com