Radiation refrigeration coating containing high refractive index difference particle combination as well as preparation method and application of radiation refrigeration coating

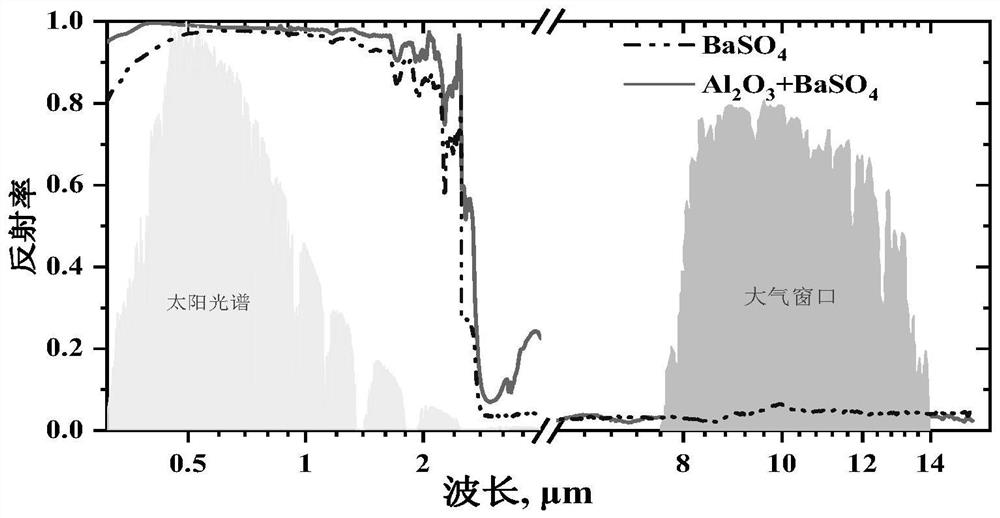

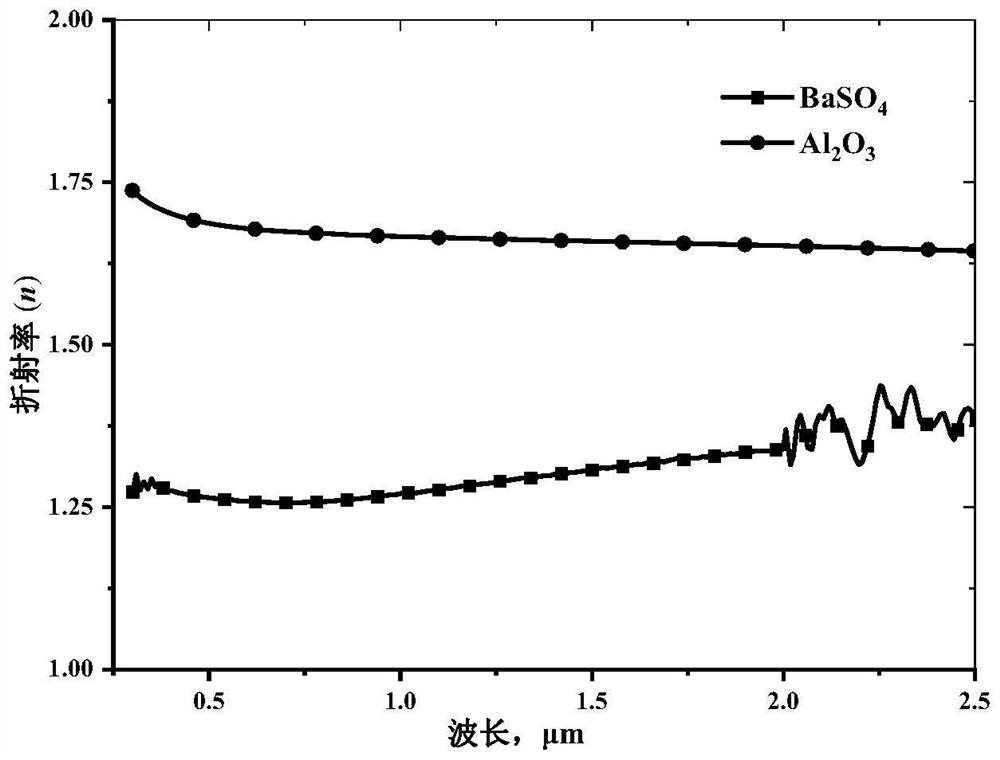

A technology with high refractive index difference and radiative cooling, applied in reflection/signal coatings, coatings, sustainable manufacturing/processing, etc., to achieve enhanced solar reflection, improved radiative cooling, and high solar reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a radiation refrigeration coating containing a combination of high refractive index difference particles, including the following components by mass: BaSO 4 25 parts, Al 2 o 3 5 parts, SiO 2 25 parts, 25 parts of fluorocarbon water-based resin, 30 parts of water, 4 parts of dispersant aminopropylamine dioleate, 3 parts of coalescent propylene glycol phenyl ether, 1.5 parts of defoamer tributyl phosphate, thickener carboxymethyl Base cellulose 3 parts and leveling agent acrylate homopolymer 3 parts, of which BaSO 4 and Al 2 o 3 The particle size of SiO is 300~500nm; 2 The particle size is 3-5μm.

[0026] The preparation method of the radiant cooling coating containing the combination of high refractive index difference particles in this embodiment: the BaSO 4 and Al 2 o 3 Grinding to a particle size of 300-500nm, the SiO 2 Grind to a particle size of 3-5 μm, mix it into the mixed system of fluorocarbon water-based resin and water, th...

Embodiment 2

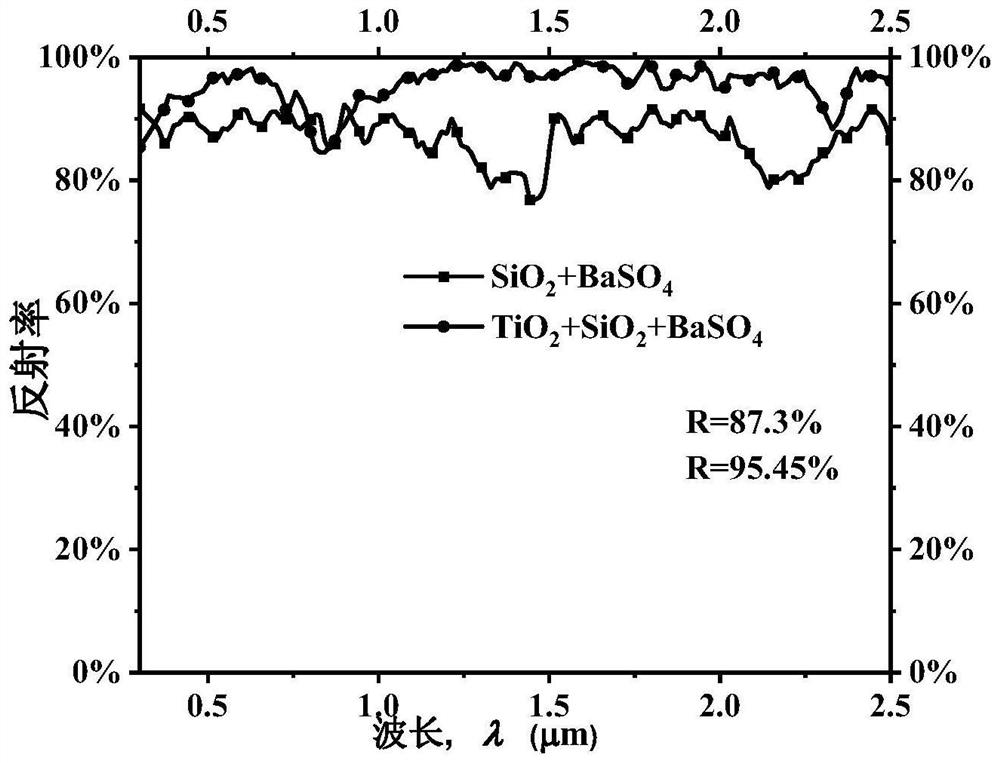

[0028] This embodiment provides a radiation refrigeration coating containing a combination of high refractive index difference particles, including the following components by mass: BaSO 4 22 parts, TiO 2 3 parts, SiO 2 15 parts, 15 parts of fluorocarbon water-based resin, 20 parts of water, 0.5 part of dispersant alkyl quaternary ammonium salt, 0.5 part of film-forming aid ethylene glycol butyl ether, 0.5 part of defoamer polyether defoamer, thickener 1 part of hydroxyethyl cellulose and 1 part of leveling agent cellulose acetate, in which BaSO 4 and TiO 2 The particle size of SiO is 300~500nm; 2 The particle size is 3-5μm.

[0029] The preparation method of the radiant cooling coating containing the combination of high refractive index difference particles in this embodiment: the BaSO 4 and TiO 2Grinding to a particle size of 300-500nm, the SiO 2 Grind to a particle size of 3-5 μm, mix it into the mixed system of fluorocarbon water-based resin and water, then add d...

Embodiment 3

[0031] This embodiment provides a radiation refrigeration coating containing a combination of high refractive index difference particles, including the following components by mass: BaSO 4 22 parts, ZnO 7 parts, Si 3 N 4 20 parts, 20 parts of water-based modified silicone resin, 25 parts of water, 2 parts of dispersant polycarboxylate sodium salt, 2 parts of film-forming aid benzyl alcohol, 1.0 parts of defoamer silicone defoamer, thickener A 2 parts of base cellulose and 2 parts of leveling agent silicone, of which BaSO 4 The particle size of ZnO and ZnO are both 300~500nm; Si 3 N 4 The particle size is 3-5μm.

[0032] The preparation method of the radiant cooling coating containing the combination of high refractive index difference particles in this embodiment: the BaSO 4 and ZnO to a particle size of 300-500nm, Si 3 N 4 Grind to a particle size of 3-5 μm, mix it into the mixed system of water-based modified silicone resin and water, then add dispersant, film-formi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com