Mechanical stripping method for preparing high-concentration graphene slurry from graphite and application of mechanical stripping method in preparation of polar plate material

A mechanical exfoliation and graphene technology, applied in graphene, chemical instruments and methods, fuel cells, etc., can solve the problems of difficult molding process, poor corrosion resistance, and difficult machining, and achieve convenient size adjustment, low equipment requirements, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

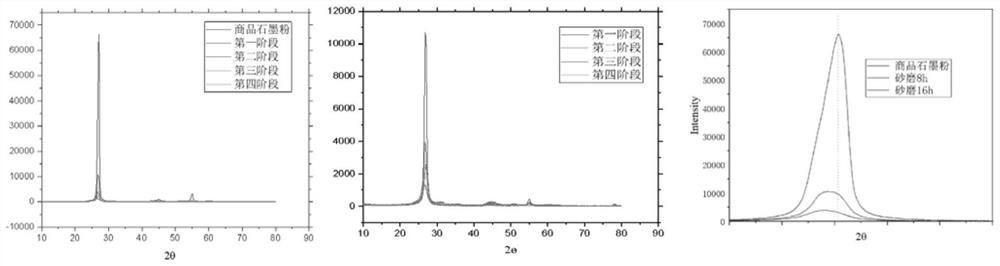

[0057] Embodiment 1: the mechanical exfoliation method of graphene prepared from graphite

[0058] Weigh 360g of commercial graphite powder, 15g of polyacrylic acid, 5g of sodium carboxymethylcellulose (CMC), 10g of lithium chloride and 5g of sodium borohydride into the barrel of the sand mill, then add 1800ml of deionized water, and start stirring The paddle rotates slowly first to pre-mix the deionized water and the material in the bucket to form a slurry, and then adjust the rotation speed of the stirring paddle so that the slurry can be stirred evenly at a faster speed (rotation speed is 200-300r / min), and the slurry is fully stirred 30min; Weigh 1.3kg of zirconium beads with a diameter of 0.8mm and add them into the grinding chamber. min until the rotation speed reaches 2400r / min; record the grinding time (about 8h, the first grinding time can be extended appropriately).

[0059] After 8 hours, turn off the sand mill, take part of the grinding slurry in a petri dish, sea...

Embodiment 2

[0062] Embodiment 2: the mechanical exfoliation method of graphene prepared from graphite

[0063] Take by weighing 360g commercial graphite powder, 10g polyacrylic acid, 5g water-based polyurethane (water-based polyurethane uses water as solvent, no pollution, safe and reliable, excellent mechanical properties, good compatibility and easy modification) and 5g sodium carboxymethyl cellulose ( CMC), 10g of lithium chloride and 5g of sodium borohydride are put into the barrel of the sand mill, then add 1800ml of deionized water, turn on the stirring paddle and rotate slowly so that the deionized water and the material in the barrel are pre-mixed into a slurry , finally adjust the rotating speed of the stirring paddle so that the slurry can be evenly stirred faster (rotating speed is 200-300r / min), fully stir the slurry for 30min; take 1.3kg of zirconium beads with a diameter of 0.8mm and add them into the grinding chamber, First set the rotation speed to 400r / min, adjust the pum...

Embodiment 3

[0067] Embodiment 3: graphite prepares the mechanical exfoliation method of graphene

[0068] Take by weighing 180g commercial graphite powder, 10g polyacrylic acid and 10g sodium carboxymethyl cellulose (CMC), polyvinyl alcohol 2g, lithium chloride 10g and sodium borohydride 5g are put into the feed bucket of sand mill, add 1800ml behind to remove For ionized water, turn on the stirring paddle to rotate slowly to pre-mix the deionized water and the material in the bucket into a slurry, and then adjust the speed of the stirring paddle so that the slurry can be stirred evenly and quickly (rotating speed is 200-300r / min), Fully stir the slurry for 30 minutes; weigh 1.3kg of zirconium beads with a diameter of 0.8mm and put them into the grinding chamber, first set the speed at 400r / min, adjust the pump to start working (about 4 to 5s for one pumping), and then every Increase the rotation speed by 500r / min until the rotation speed reaches 2400r / min; record the grinding time (about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com