Polishing pad

A polishing pad and polishing layer technology, which is applied in the field of polishing pads, can solve problems such as performance degradation, recovery performance degradation, and uneven grinding rate, and achieve high yield, small fluctuations, and stable manufacturing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of the above polyurethane resin is as follows: put the polyfunctional isocyanate into a 1L three-necked bottle, increase the reaction temperature to 70°C to 90°C within 30 to 60 minutes, and after the polyfunctional isocyanate is completely melted, start the agitator, and the stirring speed 300-500 rpm. The first polyol is dissolved and added dropwise to the polyfunctional isocyanate, and the dropping time is controlled within 1.5-3 hours. After the dropwise addition is complete, add the catalyst, continue the heat preservation reaction at 80°C to 110°C for 2 to 5 hours, and then perform defoaming treatment on the reactant, and control the vacuum degree of defoaming to -0.096MPa, 80°C, 60 minutes , to obtain a prepolymer, the free -NCO mass percentage is 6.5-9.6%; add a chain extender and a solvent to the above-mentioned prepolymer, mix well, and react at 80°C for 200min-300min to obtain a polyurethane resin The solution, after removing the solve...

Embodiment

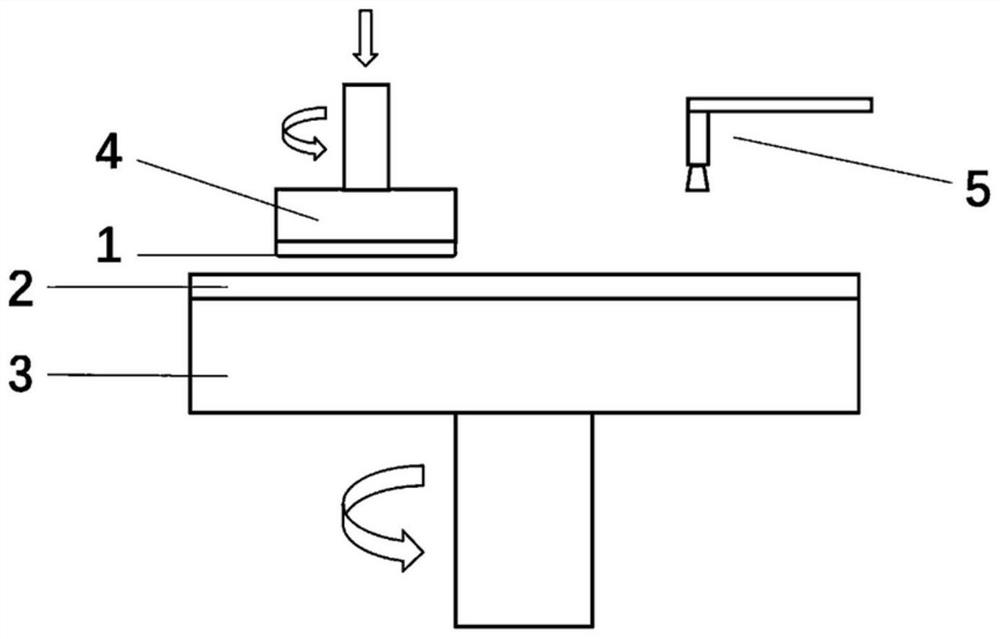

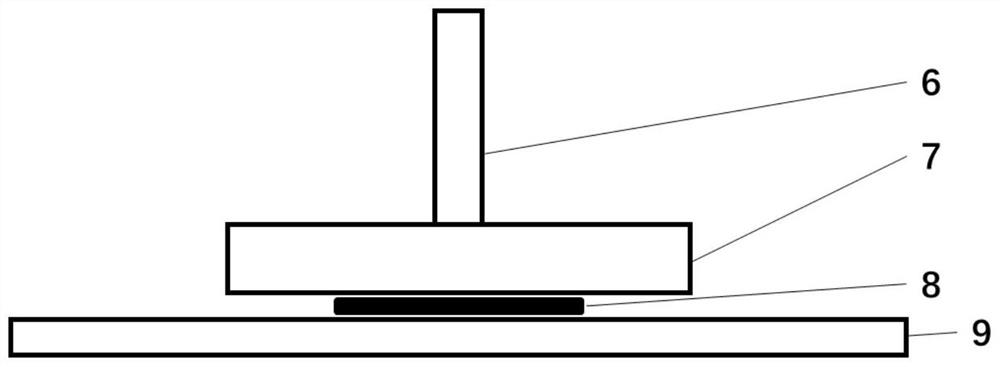

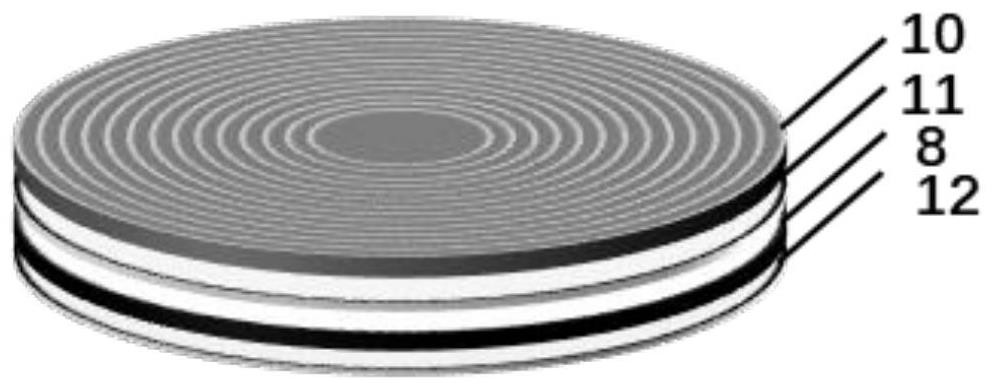

[0104] The present invention will be further described below with reference to the schematic examples shown in the accompanying drawings. Through the following description, the advantages of various aspects of the present invention will be more obvious. In the accompanying drawings, the same reference numerals refer to the same components. In the schematic drawings The shape and size of each component are for illustration only, and cannot be recognized as reflecting the actual shape, size and absolute position.

[0105] DMF: N,N-dimethylformamide;

[0106] MDI: diphenylmethane diisocyanate;

[0107] TDI: toluene diisocyanate;

[0108] PU: foamed polyurethane;

Synthetic example 1

[0109] Polyurethane resin synthesis example 1-A1

[0110] Put 6 parts by mass of TDI and 17.5 parts by mass of MDI into a 1L three-necked flask, raise the reaction temperature to 70°C within 30 minutes, and after the TDI and MDI are completely melted, start the stirrer at a stirring speed of 300 rpm. After dissolving 57 parts by mass of polyester polyol Kurapol P-2010 and 3.4 parts by mass of polyether polyol PPG3000, they were added dropwise to TDI and MDI, and the dropping time was controlled at 1.5 hours. After the dropwise addition is completed, add 0.005 parts by mass of dibutyltin dilaurate, continue to keep warm at 80°C for 2 hours, and then perform defoaming treatment on the reactant. , 60 minutes, to obtain the prepolymer, its free -NCO mass percentage is 7.5%; add 6.2 mass parts of 1,4-butanediol and 47 mass parts of DMF to the above prepolymer, after mixing uniformly, React at 80°C for 200 minutes to obtain the desired polyurethane resin solution, and then remove t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com