Optical probe mounting and debugging device for machining center and use method of optical probe mounting and debugging device

A technology for optical probes and machining centers, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the complex structure of optical measurement equipment and the inability to realize the cumbersome process of changing, installing, debugging, and maintaining multiple machining centers and other problems, to achieve the effect of simple and fast debugging process, wide range of use and wide range of angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The structure of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments. It should be noted that this embodiment is illustrative rather than limiting.

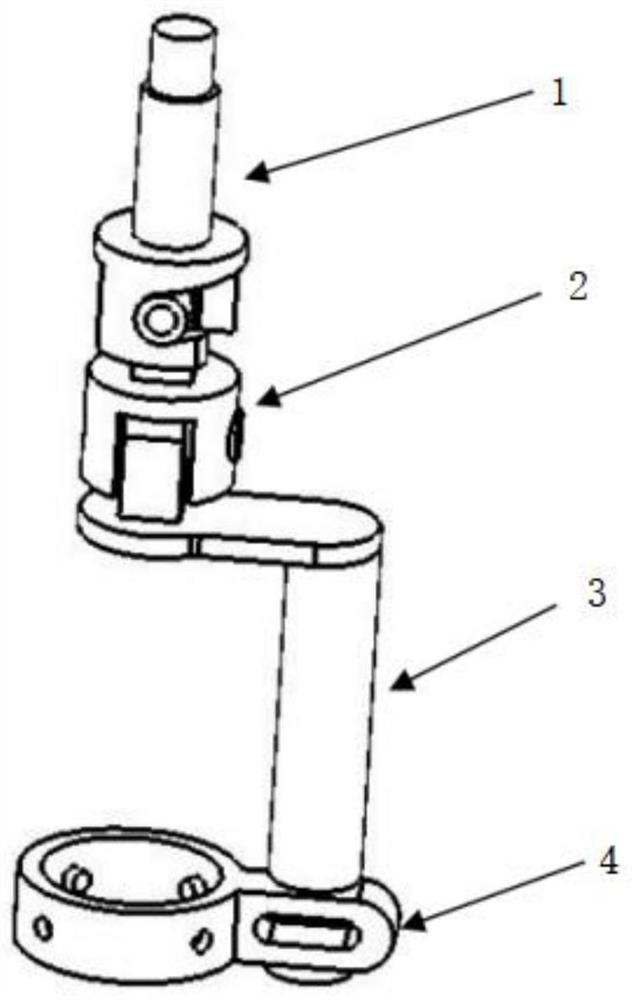

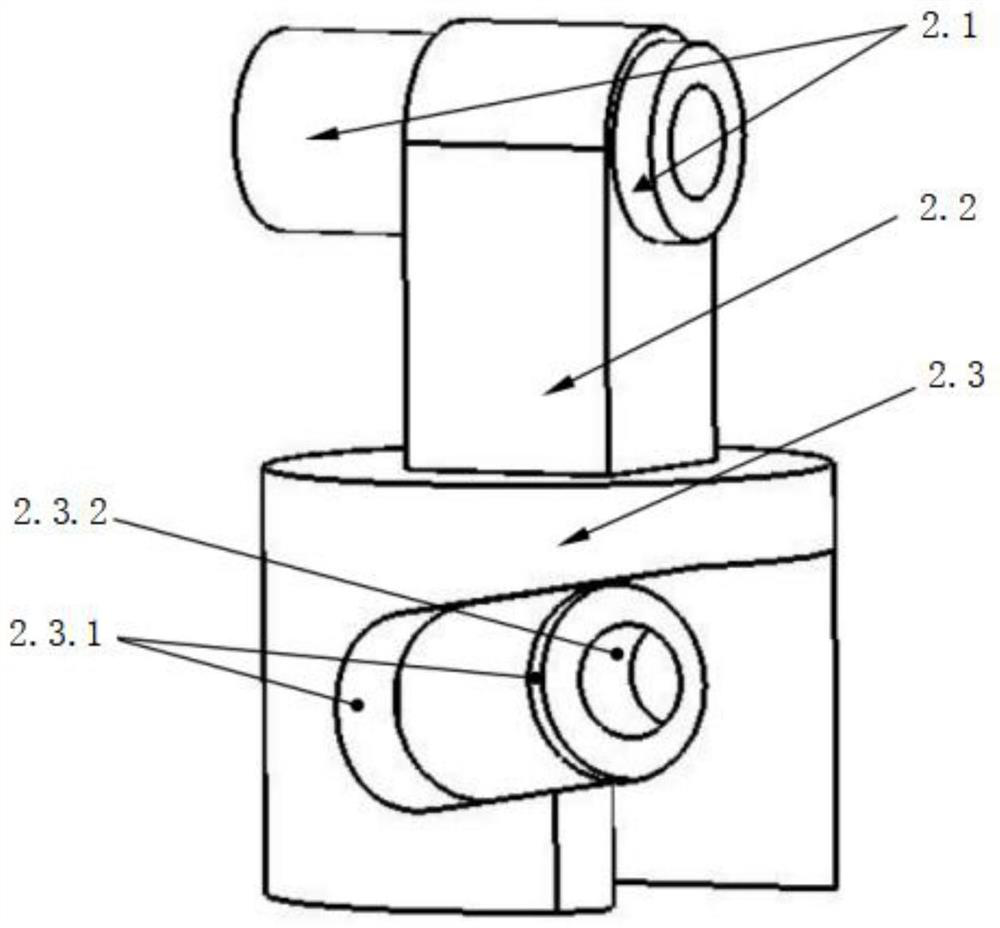

[0049] A device for installing and debugging an optical probe on a machining center, please refer to Figure 1-5 , including a mounting head 1 , a first rotating adjustment member 2 , a second rotating adjusting member 3 and an optical probe fixing member 4 .

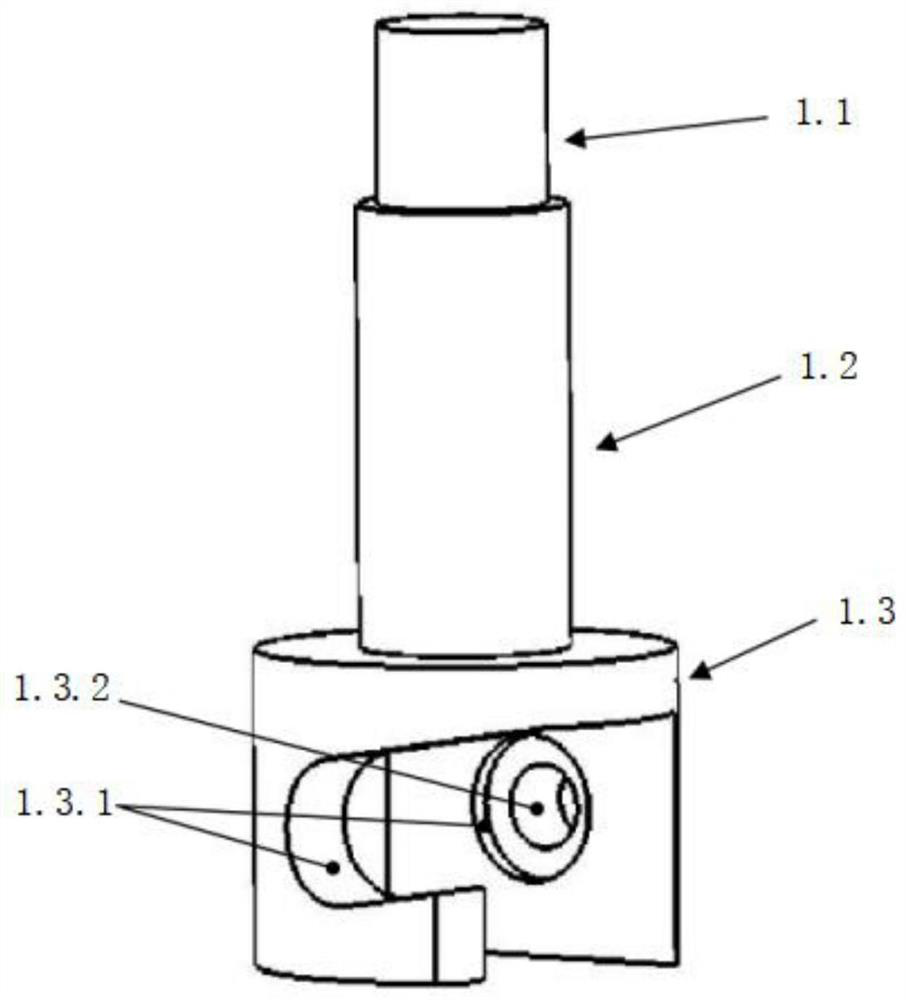

[0050] The installation head is a three-stage structure, the top 1.1 of the installation head is an external thread column structure that can be fixedly connected with the magnetic table base, the middle part 1.2 of the installation head is a general tool handle installation column structure, and the bottom 1.3 of the installation head is provided with The hollow cylinder structure with side openings is provided with a circular positioning groove 1.3.1 along the Y-axis direction on the hollow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com