Semi-automatic clamp for lathe

A semi-automatic fixture technology, applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems of low clamping efficiency and inconvenient operation for operators, so as to reduce work intensity, improve processing efficiency, clamp reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] This embodiment is a semi-automatic fixture for machine tools. The fixture can clamp multiple workpieces at the same time, automatically clamps, and has a large clamping range, which can not only improve processing efficiency, but also reduce the work intensity of operators.

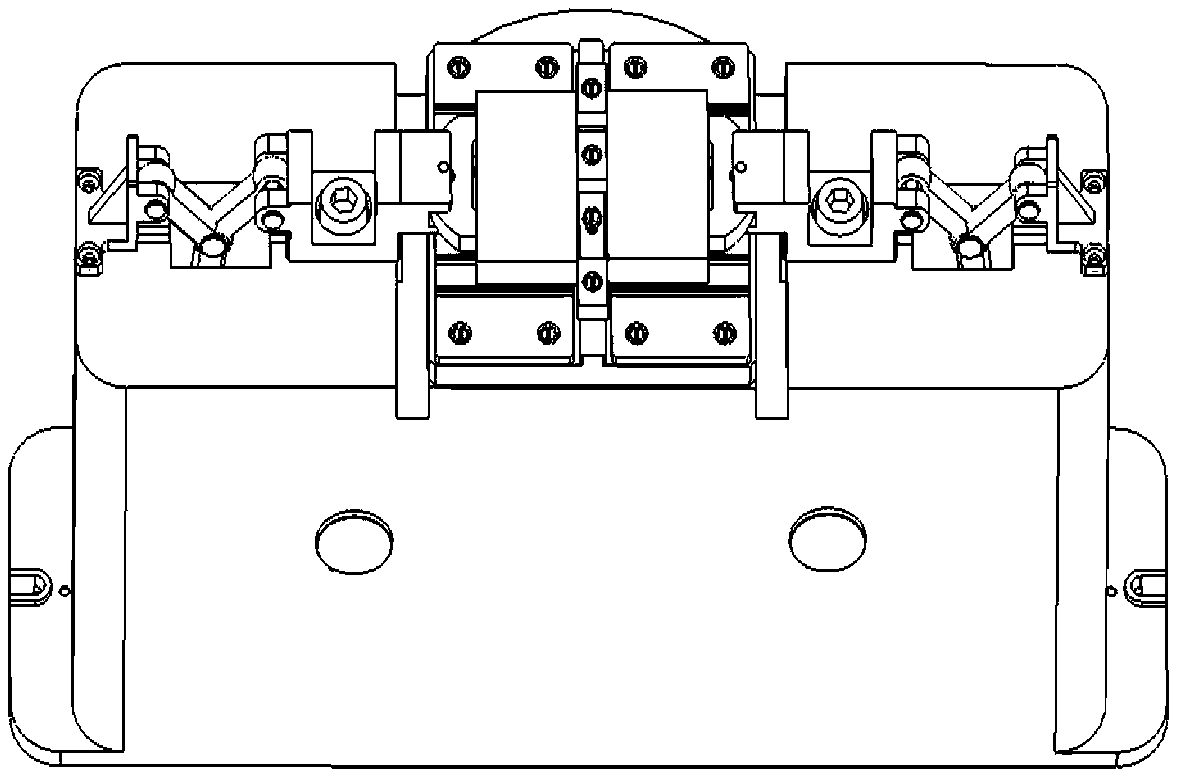

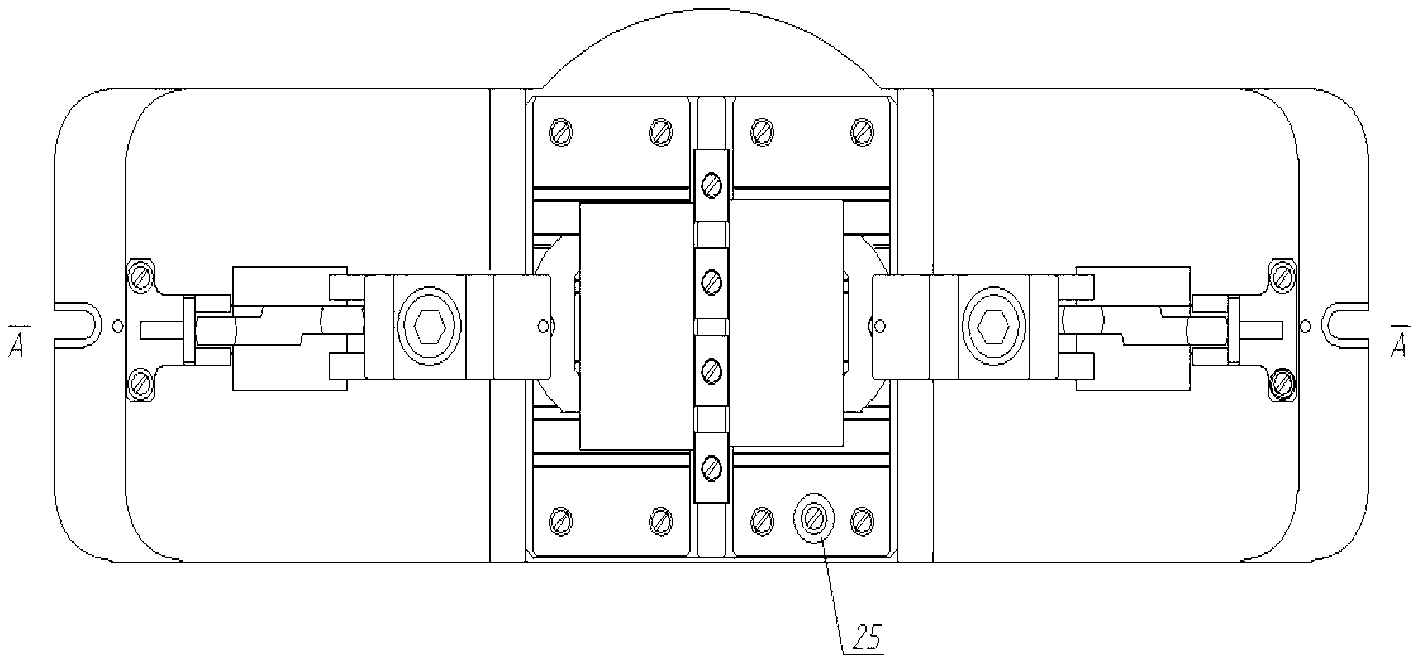

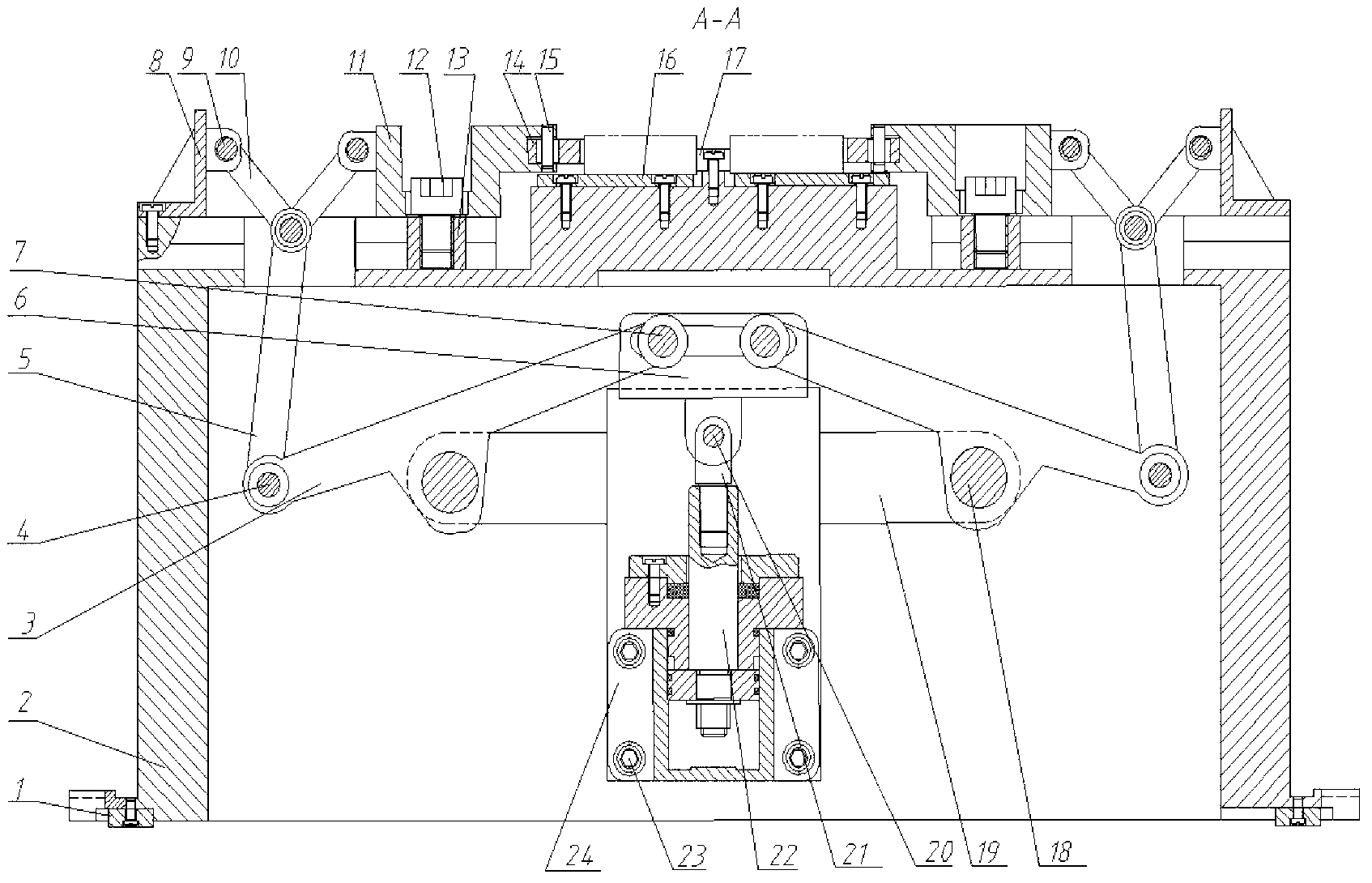

[0024] refer to figure 1 , figure 2 , image 3 , Figure 5 , the present invention takes the clip body as the main support mechanism, including positioning key 1, clip body 2, rotating rod 3, short shaft 4, intermediate connecting rod 5, connecting rod sliding seat 6, sliding shaft 7, connecting rod support 8, long Shaft 9, push rod 10, sliding seat 11, hexagon socket head cap screw 12, T-shaped slider 13, arc-shaped pressing block 14, pin 15, positioning plate 16, positioning block 17, supporting shaft 18, supporting rod 19, hinge shaft 20 , threaded connecting rod 21, piston rod 22, screw 23, foot type hydraulic cylinder 24, tool setting block 25, hydraulic cylinder seat 26; clamp body 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com