Multifunctional punching device for motor production and machining

A punching device and multi-functional technology, applied in electromechanical devices, positioning devices, metal processing equipment, etc., can solve the problems of inability to quickly detect motor casings, improve the difficulty of operation by staff, and inability to quickly eliminate defective products, and achieve protection. The effect is good, the operation difficulty is reduced, and the processing accuracy is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

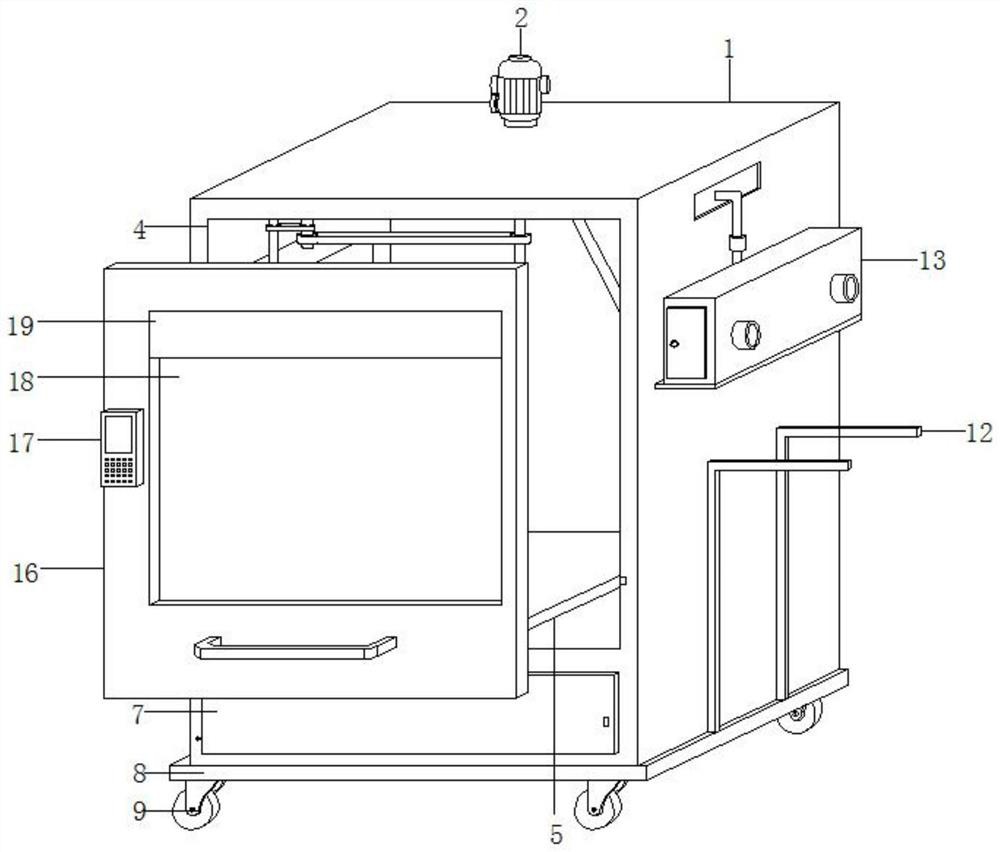

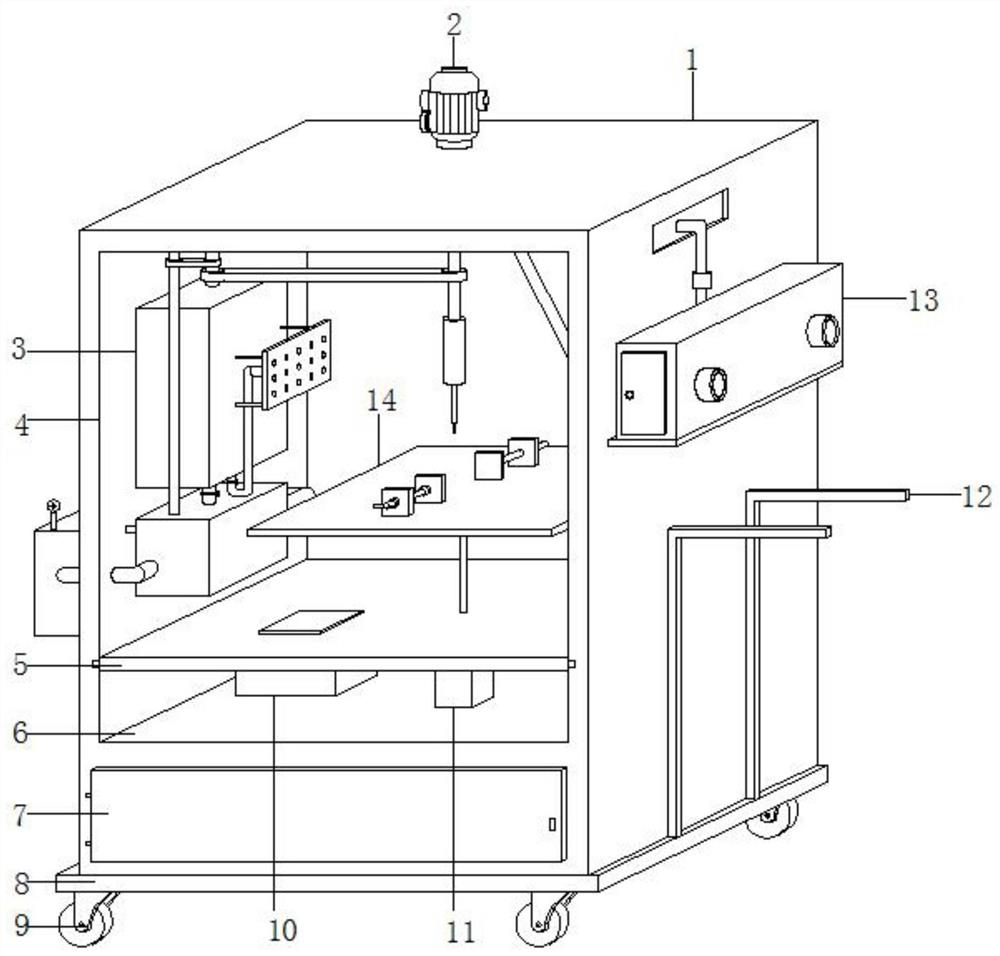

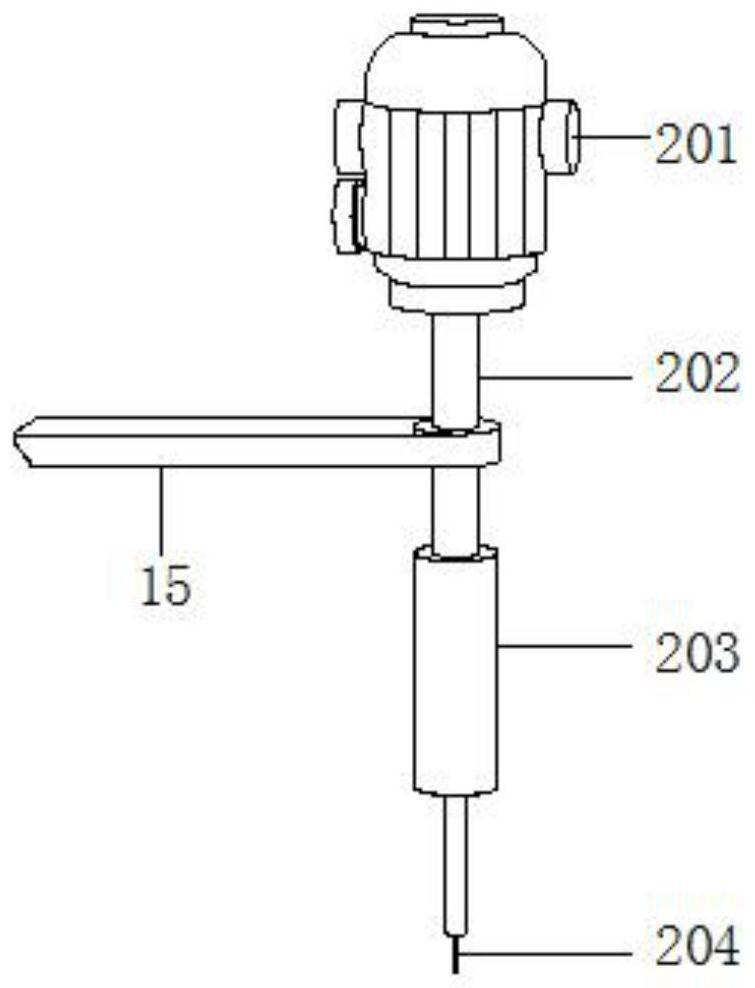

[0046] refer to figure 1 , 2 , 3, 11, 12, a multifunctional punching device for motor production and processing, including a device shell 1, an operation port 4 is provided at the front end of the device shell 1, a punching assembly 2 is fixedly installed in the middle of the upper end of the device shell 1, and the punching The lower end of the hole assembly 2 runs through the device casing 1 and extends to the inside of the device casing 1. The installation platform 5 is slidably installed on the inner wall of the device casing 1 through the slide rail. 16 is arranged at the operation port 4, and the front end of the door panel 16 is fixedly equipped with a transparent observation window 18, a display screen 19 and a control panel 17, and the display screen 19 is located above the transparent observation window 18, and the control panel 17 is located on the left side of the transparent observation window 18. The lower end of the table 5 is fixed with a measuring mechanism 1...

Embodiment 2

[0052] refer to Figure 4-7 , a multifunctional punching device for motor production and processing. Compared with Embodiment 1, this embodiment also includes an auxiliary punching mechanism 3, and the auxiliary punching mechanism 3 includes a first mounting shell 301, a second mounting shell 309 and a third mounting shell. The installation shell 312, the first installation shell 301 and the second installation shell 309 are fixedly installed on the left end surface inside the device shell 1, and are all located above the installation platform 5, the first installation shell 301 is located above the second installation shell 309, and the third installation shell 312 is fixedly installed on the left end surface of the device casing 1, and the middle part of the upper end of the first installation casing 301 is movable through a connecting shaft 304. The connecting shaft 304 is arranged along the vertical direction, and the lower end of the connecting shaft 304 extends to the ins...

Embodiment 3

[0058] refer to Figure 8-9 , a multifunctional punching device for motor production and processing. Compared with Embodiment 1, this embodiment also includes a measuring mechanism 10. The measuring mechanism 10 includes a fixed shell 1001. The fixed shell 1001 is fixedly installed on the lower end of the mounting table 5. The fixed shell 1001 A pressure sensor 1004 is fixedly installed at the inner bottom, and a pressure guide bump 1002 is attached to the sensing end of the pressure sensor 1004. The upper end of the pressure guide bump 1002 runs through the fixed shell 1001, and a measuring board 1003 is installed on the upper end of the measuring board 1003. The activity runs through the installation platform 5 and extends above the installation platform 5;

[0059] The pressure guiding protrusion 1002 is slidably attached to the inner wall of the fixed shell 1001 along the vertical direction.

[0060] Working principle: The motor casing after punching can be put on the mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com