Magnesium-based multifunctional composite active coating as well as preparation method and application thereof

An active coating and functional technology, applied in the field of magnesium-based multifunctional composite active coating and its preparation, can solve the problems of implants losing mechanical integrity, poor biocompatibility, and rapid corrosion, and achieve good cell compatibility Good adhesion, good adhesion, corrosion inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A kind of preparation method of magnesium-based multifunctional composite active coating of the present invention comprises the following steps:

[0047] (1) Prepare ammonium trifluorotitanate active coating on magnesium-based surface by hydrothermal reaction method;

[0048] (2) Using a hydrothermal reaction method to modify the ammonium trifluorotitanate active coating with functional organic molecules;

[0049] (3) Constructing a metal-organic framework active coating on the surface of functional organic molecules by a solvothermal method, and the functional organic molecule layer is used to improve the heterogeneous nucleation of metal-organic framework grains on the surface of the ammonium trifluorotitanate layer .

[0050] In some embodiments, step (1) adopts hydrothermal reaction method to prepare NTiF coating on magnesium-based surface:

[0051] First, use 400#, 1000#, 2000# sandpaper to The surface was polished and ultrasonically cleaned in ethanol and acet...

Embodiment 1

[0067] Step 1, adopting hydrothermal reaction method to prepare NTiF coating on magnesium-based surface;

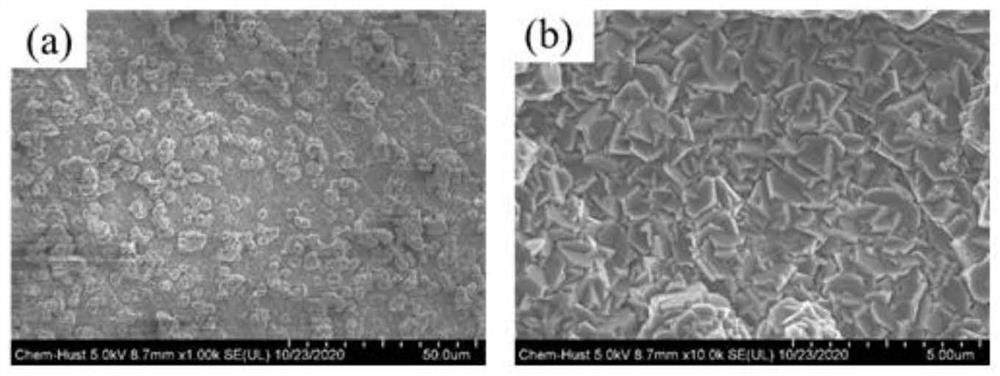

[0068] First, use 400#, 1000#, 2000# sandpaper to The surface was polished and ultrasonically cleaned in ethanol and acetone in turn, and dried for use. Configure 0.3mol / L NH 4 F aqueous solution, take the prepared 250μL NH 4 F solution and 300μL 40% HF solution were added to 15mL absolute ethanol, mixed completely under magnetic stirring for 10min, then added 500μL tetraisopropyl titanate (TBOT), and magnetically stirred again for 15min, after TBOT was fully hydrolyzed, together with The surface-treated magnesium-based material was placed in a 50mL polytetrafluoroethylene reactor liner for hydrothermal reaction. The hydrothermal temperature was 160°C and the hydrothermal time was 8h. After cooling to room temperature, the samples were taken out and rinsed with ethanol and acetone respectively. Dry for later use to obtain NTiF coating, such as figure 1 shown.

[006...

Embodiment 2

[0074] Step 1, adopting hydrothermal reaction method to prepare NTiF coating on magnesium-based surface;

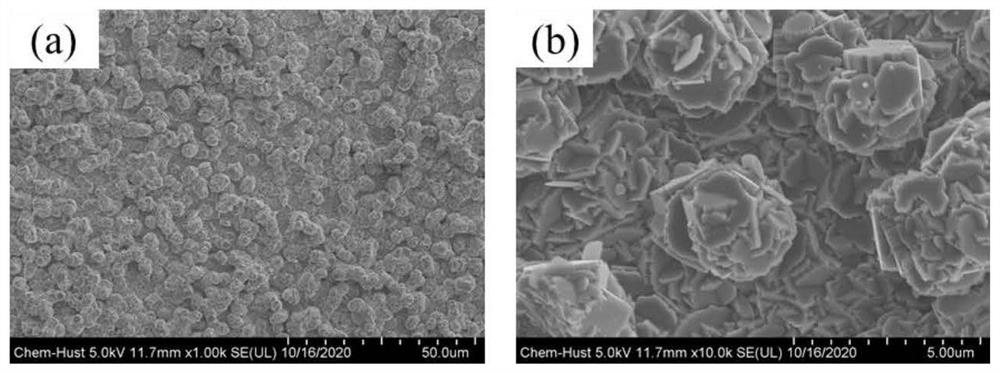

[0075] First, use 400#, 1000#, 2000# sandpaper to The surface was polished and ultrasonically cleaned in ethanol and acetone in turn, and dried for use. Configure 0.3mol / L NH 4 F aqueous solution, take the prepared 250μL NH 4 F solution and 300μL 40% HF solution were added to 15mL absolute ethanol, mixed completely under magnetic stirring for 10min, then added 500μL tetraisopropyl titanate (TBOT), and magnetically stirred again for 15min, after TBOT was fully hydrolyzed, together with The surface-treated magnesium-based material was placed in a 50mL polytetrafluoroethylene reactor liner for hydrothermal reaction. The hydrothermal temperature was 140°C and the hydrothermal time was 6h. After cooling to room temperature, the samples were taken out and rinsed with ethanol and acetone respectively. Dry for later use to obtain NTiF coating, such as figure 2 shown.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com