Thin film, preparation method thereof and battery

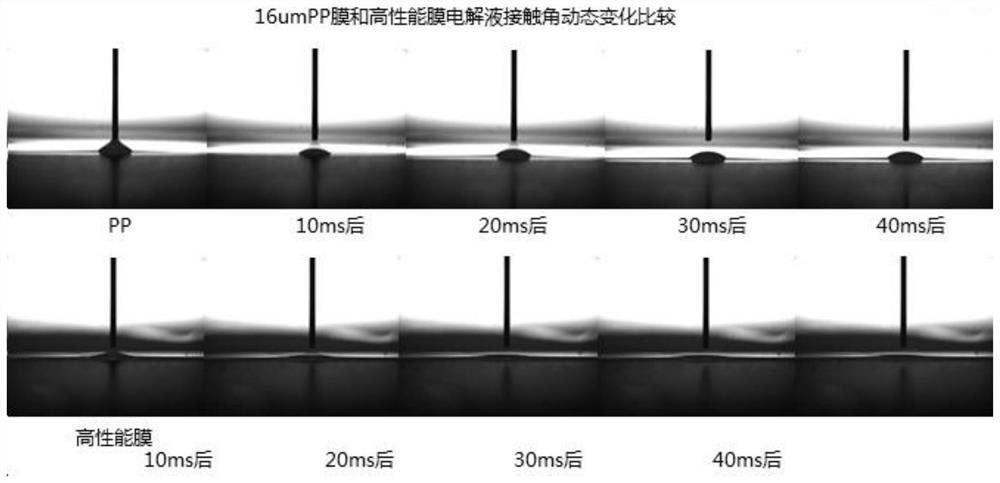

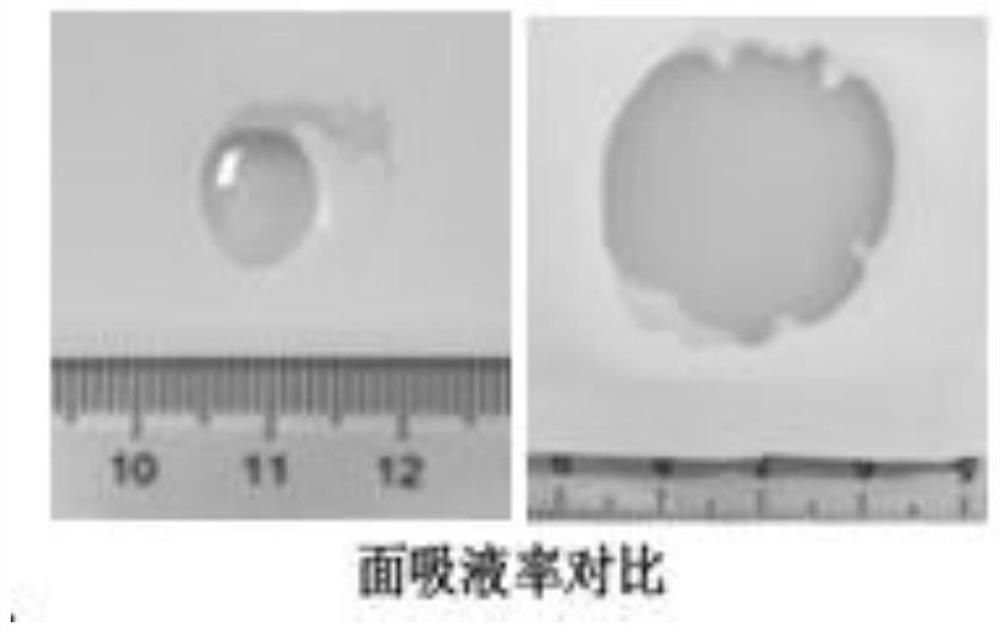

A thin-film and dry-process technology, applied in secondary batteries, battery components, circuits, etc., can solve problems affecting battery performance, poor adhesion, coating peeling, etc., to improve lyophilicity and reduce crystallinity , The effect of improving battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] In this embodiment, the raw material used to prepare the middle layer of the film is polypropylene with a weight average molecular weight of 500,000 and a melt index of 0.5 g / 10 min.

[0064] The raw materials used to prepare the surface layer of the film are polypropylene and maleic anhydride. By mass, polypropylene:maleic anhydride=60:40, the weight average molecular weight of polypropylene is 400,000, and the melt index is 1.2g / 10min.

[0065] The thin film preparation method of embodiment 1~7 is as follows:

[0066] 1. Casting: Feed thermoplastic resin particles and modified substances into a single-screw extruder (one extruder, two melting and plasticizing runners for melting the surface layer raw materials and the middle layer raw materials respectively) through the feeding system, Melt extrusion, the extrusion temperature is 140-280°C, after the melt passes through the primary filter and the secondary filter, it passes through the three-layer splitter, enters the...

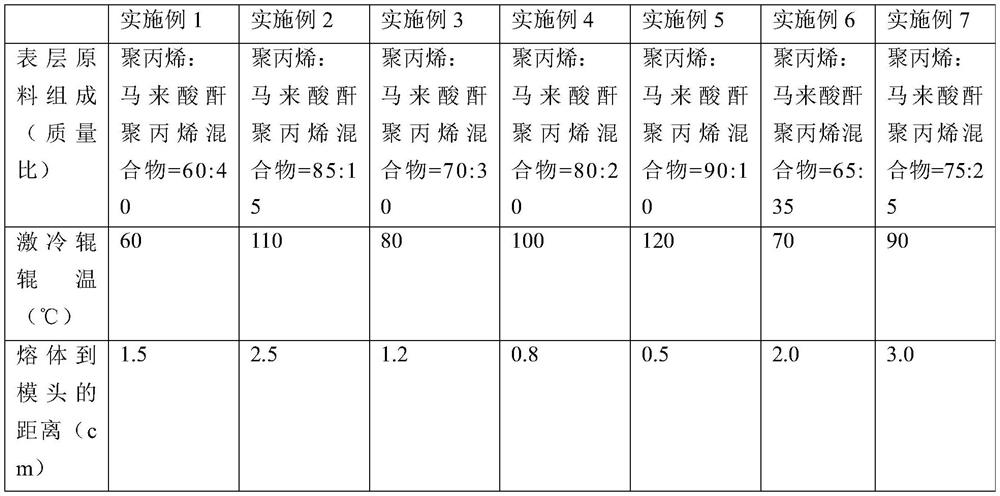

Embodiment 2~7

[0074] Examples 2-7 were carried out with reference to Example 1. The differences are shown in Table 1 and Table 2. The differences include the different thicknesses of the prepared separators. The specific thicknesses are shown in Table 2. The specific process parameters of each embodiment are shown in Table 1.

[0075] Table 1

[0076]

[0077]

[0078] The basic physical and chemical performance indicators of the high-performance multilayer lithium-ion battery separators of Examples 1-7 are shown in Table 2.

[0079] Table 2

[0080]

[0081] The thickness test method is carried out according to "GB / T 6672-2001 Mechanical Measurement Method for Thickness Determination of Plastic Films and Sheets". It is measured by a Marr thickness gauge with a flat contact head. Before the measurement, the instrument is calibrated and cleared, and the contact surface is kept clean. The TD direction of the film is measured at intervals of 5 cm, and the average value of the 5 point...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com