Mercerizing fatliquor as well as preparation method and application thereof

A fatliquor and mercerizing technology, applied in the field of mercerizing fatliquor, can solve the problems of not very strong mercerizing feeling, poor skin oil feeling, easy to burn the suede, etc., and achieve good absorption and penetration effect and anti-aging performance. Strong, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

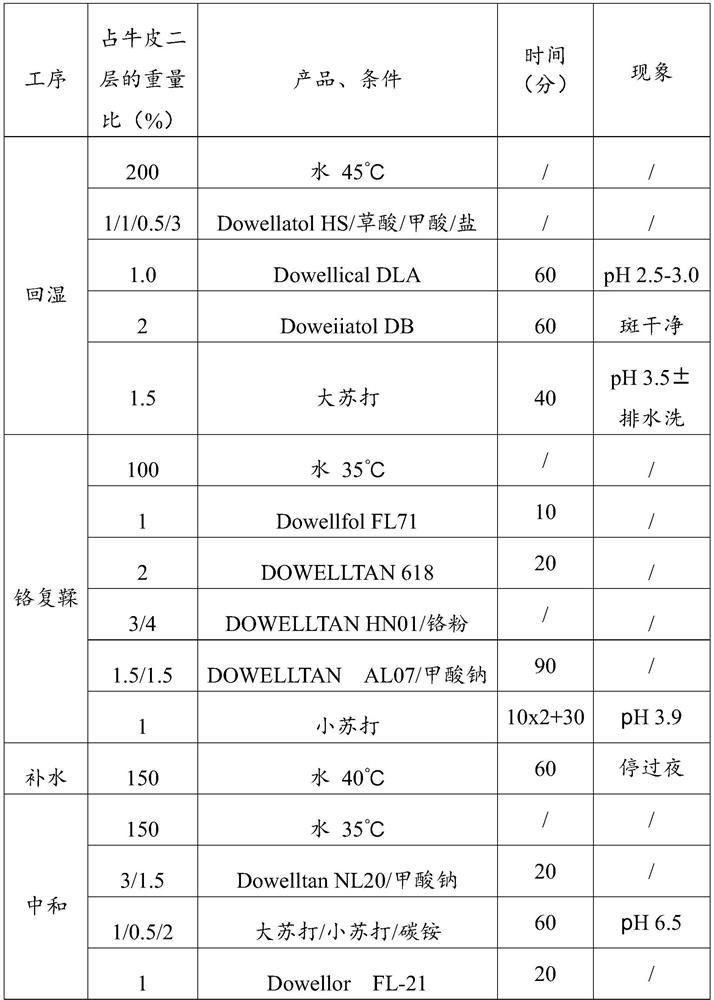

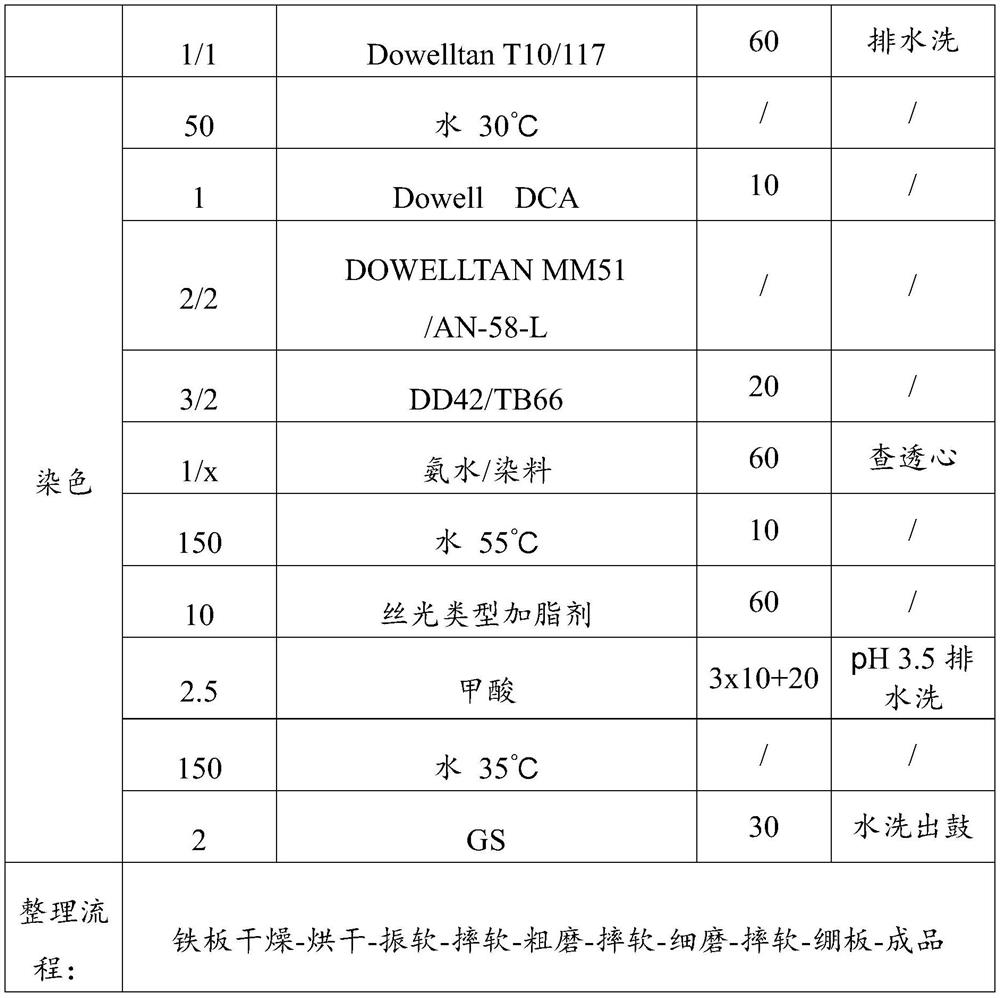

Method used

Image

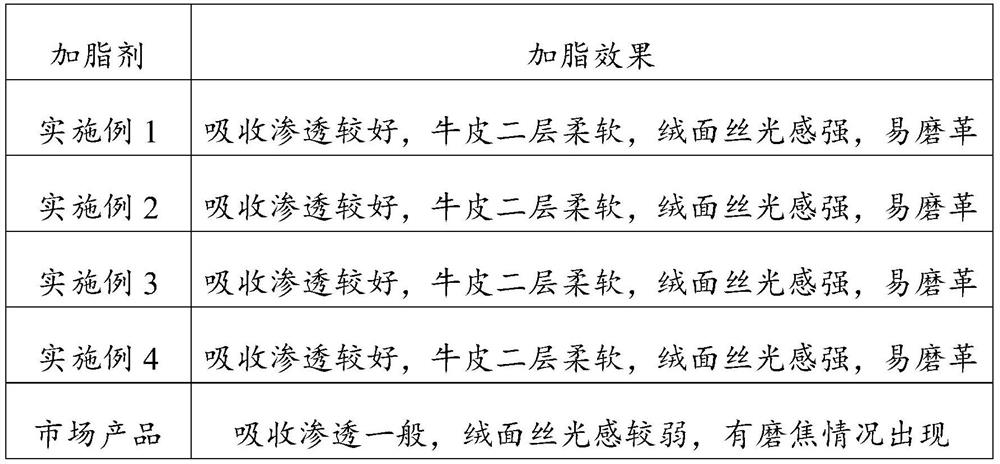

Examples

Embodiment 1

[0024] The mercerized fatliquor of the present embodiment is prepared in the following manner:

[0025] S1: Add 30g of refined lanolin, 70g of refined lard, 15g of diethanolamine, and 0.2g of sodium methoxide into the reaction kettle, heat up to 130-140°C, and react 4-6 under nitrogen as a protective gas. Hours; then lower the temperature to 80-90°C, add 25g of maleic anhydride, react for 1 hour under vacuum conditions (vacuum degree <-0.06MPa), and lower the temperature to 60-65°C to obtain reaction solution A.

[0026] S2: Preparation of sodium metabisulfite mixed solution: After mixing 25 g of sodium metabisulfite and 145 g of water evenly, add 40 g of sodium hydroxide solution with a mass fraction of 30%, the reaction is an exothermic reaction, and the temperature of the mixed solution is controlled not to exceed 40 ° C, pH 7.5 to 8.5, the reaction solution B was obtained.

[0027] S3: Add liquid B evenly to liquid A, keep the temperature stable at 60-65°C, heat it up to ...

Embodiment 2

[0030] The mercerized fatliquor of the present embodiment is prepared in the following manner:

[0031] S1: Add 50g of refined lanolin, 50g of refined lard, 20g of diethanolamine, and 0.3g of sodium methoxide into the reaction kettle, heat up to 130-140°C, and react 4-6 under nitrogen as a protective gas. Hours; then lower the temperature to 80-90°C, add 25g of maleic anhydride, react for 1 hour under vacuum conditions (vacuum degree <-0.06MPa), and lower the temperature to 60-65°C to obtain reaction solution A.

[0032] S2: Preparation of sodium metabisulfite mixed solution: After mixing 25 g of sodium metabisulfite and 145 g of water evenly, add 40 g of sodium hydroxide solution with a mass fraction of 30%, the reaction is an exothermic reaction, and the temperature of the mixed solution is controlled not to exceed 40 ° C, pH 7.5 to 8.5, the reaction solution B was obtained.

[0033] S3: Add liquid B evenly to liquid A, keep the temperature stable at 60-65°C, heat it up to ...

Embodiment 3

[0036] The mercerized fatliquor of the present embodiment is prepared in the following manner:

[0037] S1: Add 30g of refined lanolin, 70g of refined lard, 15g of diethanolamine, and 0.2g of sodium methoxide into the reaction kettle, heat up to 130-140°C, and react 4-6 under nitrogen as a protective gas. Hours; then lower the temperature to 80-90°C, add 25g of maleic anhydride, react for 1 hour under vacuum conditions (vacuum degree <-0.06MPa), and lower the temperature to 60-65°C to obtain reaction solution A.

[0038] S2: Preparation of sodium metabisulfite mixed solution: After mixing 25 g of sodium metabisulfite and 145 g of water evenly, add 40 g of sodium hydroxide solution with a mass fraction of 30%, the reaction is an exothermic reaction, and the temperature of the mixed solution is controlled not to exceed 40 ° C, pH 7.5 to 8.5, the reaction solution B was obtained.

[0039] S3: Add liquid B evenly to liquid A, keep the temperature stable at 60-65°C, heat it up to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com