Method and device for preparing ethylene-vinyl acetate-vinyl alcohol copolymer

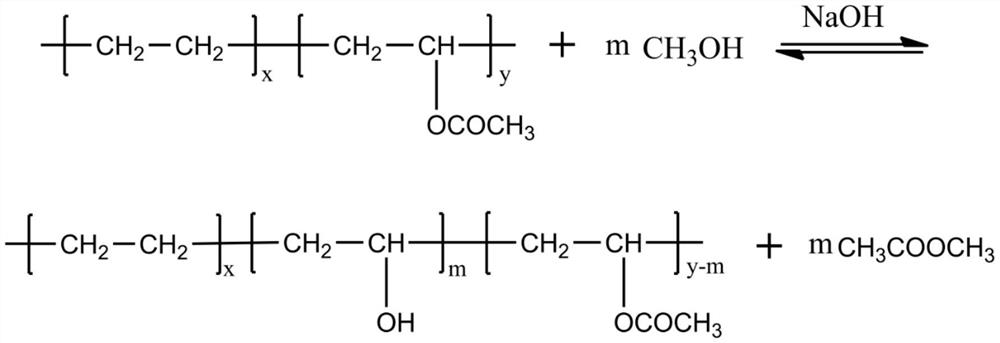

A vinyl acetate copolymer and vinyl acetate technology, which is applied in the field of preparing ethylene-vinyl acetate copolymer, can solve the problems of large consumption of fresh methanol, high equipment investment, complicated operation process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

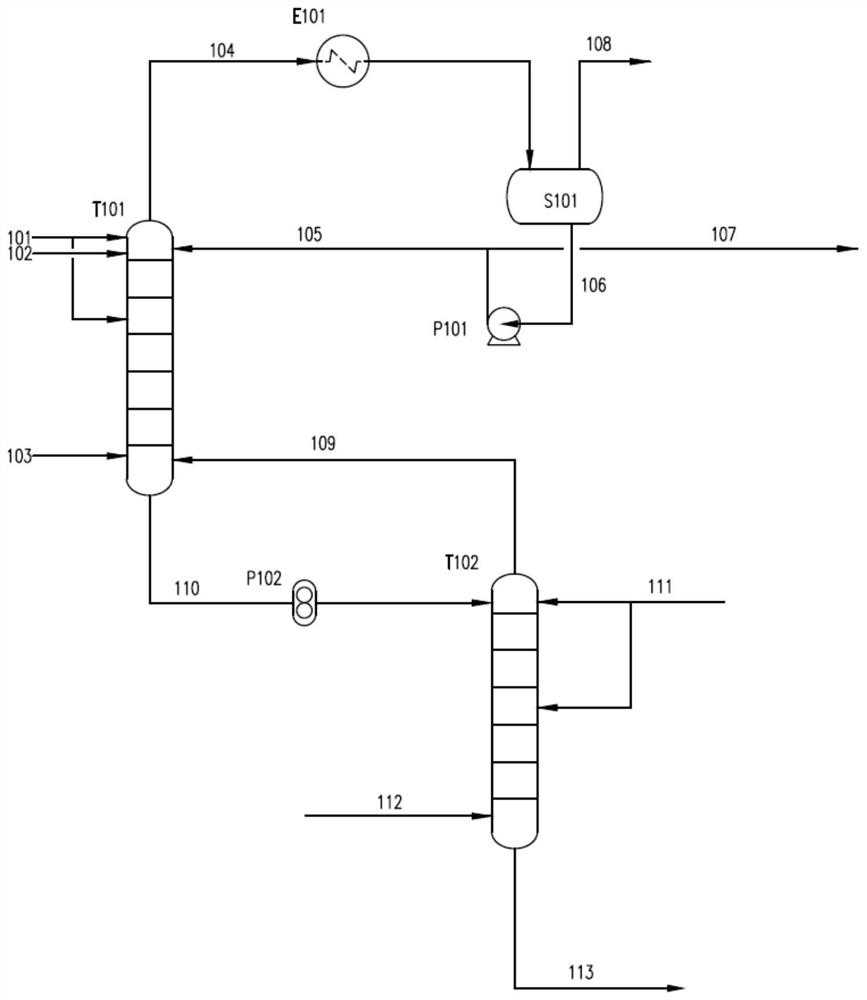

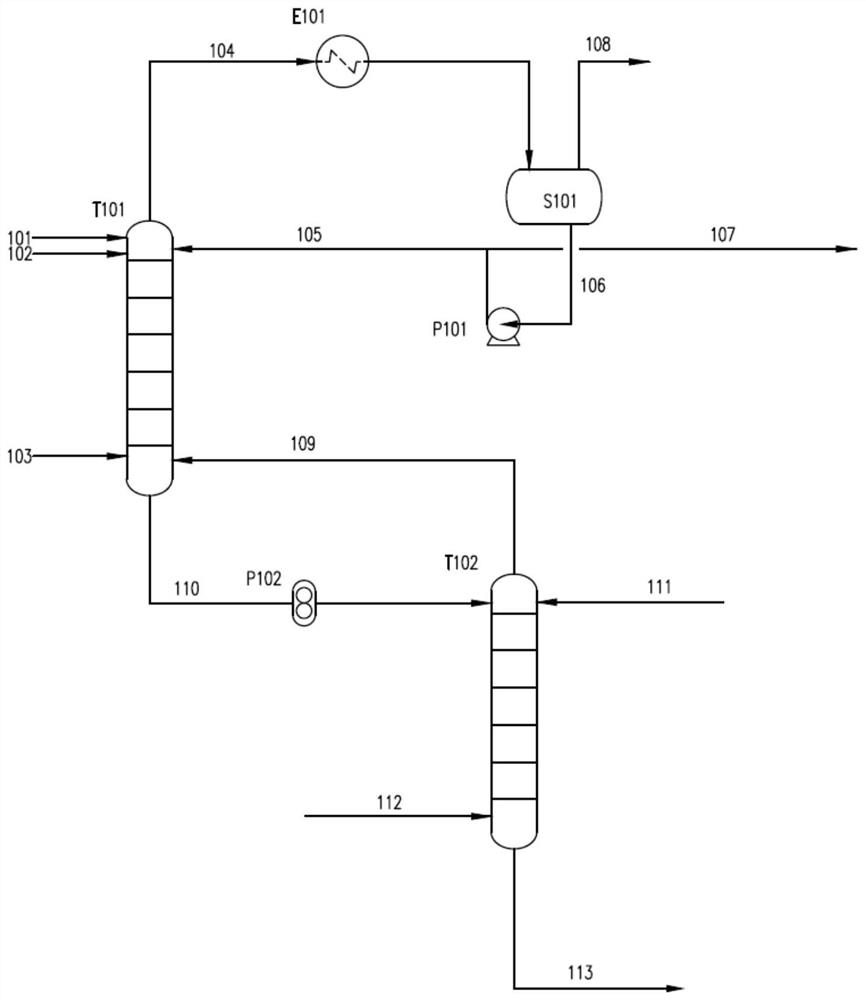

[0099] The technological process of this embodiment is as figure 1 Shown, wherein, alcoholysis tower I and alcoholysis tower II are tray towers.

[0100] In weight percentage, the polymer liquid stream of ethylene-vinyl acetate copolymer contains: 70wt% methanol, 30wt% ethylene-vinyl acetate copolymer, the temperature is 55°C, and the pressure is 0.6MPaG.

[0101] In terms of weight percentage, the concentration of sodium hydroxide lye is 5wt%, and the temperature is 25°C.

[0102] The alcoholysis tower I operating pressure is 0.32MPaG, and the alcoholysis tower I top condensate does not reflux.

[0103] The operating pressure of alcoholysis tower II is 0.57MPaG.

[0104] Alcoholysis tower I consumes fresh methanol vapor stream 103 as 0t / h, and alcoholysis tower II consumes fresh methanol vapor stream 112 as 20t / h, then the degree of alcoholysis of the ethylene-vinyl acetate alcohol copolymer polymer solution in alcoholysis tower I can reach 98.53%, the methyl acetate conte...

Embodiment 2

[0106] Embodiment is the same as embodiment 1, and difference is that alcoholysis tower I consumes fresh methanol vapor stream 103 and is 0t / h, and alcoholysis tower II consumes fresh methanol vapor stream 112 and is 25t / h, then the ethylene-vinyl acetate of alcoholysis tower I The degree of alcoholysis of the alcohol copolymer polymerization liquid can reach 98.63%, and the methyl acetate content of 110% in the tower still stream is 1990ppm. The methyl acetate content is 77ppm, and the molecular weight distribution of the ethylene-vinyl acetate copolymer product is 2.56.

Embodiment 3

[0108] Embodiment is the same as embodiment 1, and difference is that alcoholysis tower I consumes fresh methanol vapor stream 103 and is 0t / h, and alcoholysis tower II consumes fresh methanol vapor stream 112 and is 30t / h, then the ethylene-vinyl acetate of alcoholysis tower I The degree of alcoholysis of the alcohol copolymer polymerization solution can reach 98.71%, and the content of methyl acetate in the column stream 110 is 1905ppm. The methyl acetate content is 48ppm, and the molecular weight distribution of the ethylene-vinyl acetate alcohol copolymer product is 2.25.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com