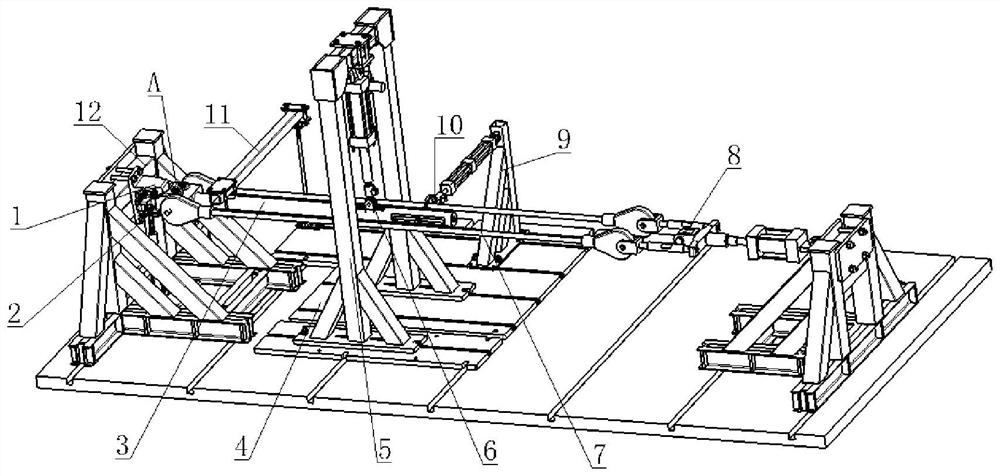

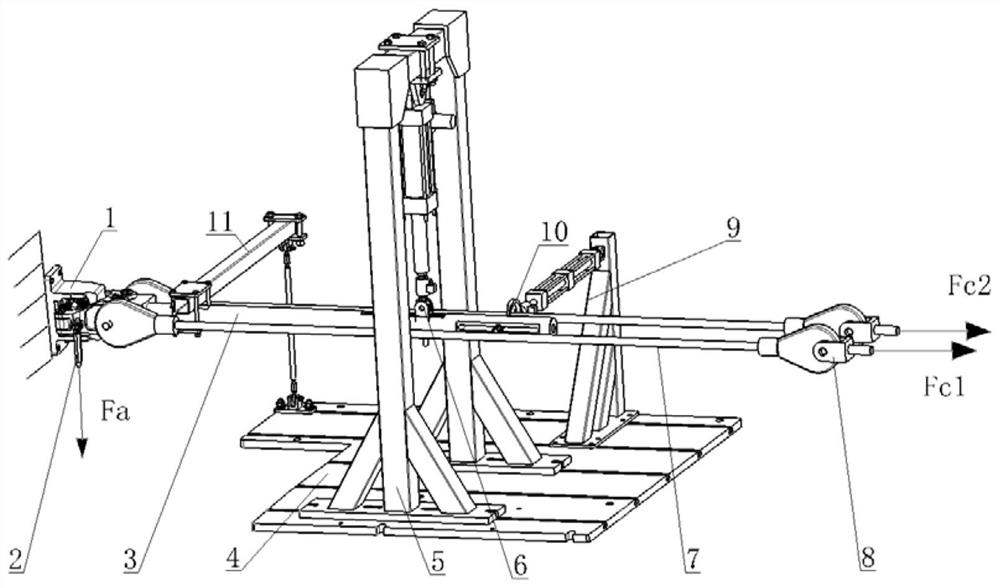

Loading test device for rigid main propeller hub connecting piece

A technology of loading test device and main propeller hub, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., which can solve the problems that rigid main propeller hub connectors cannot be used, shorten working time, and quickly The effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

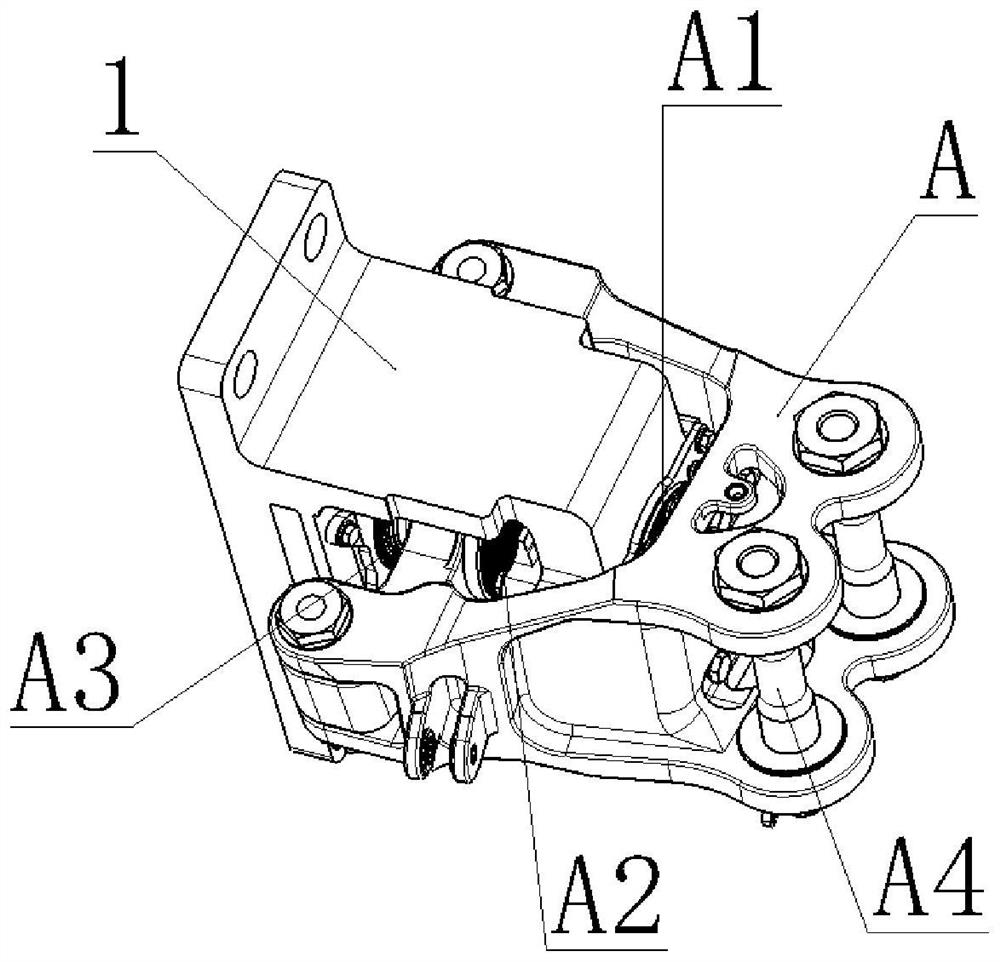

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

[0052] It has been explained in the above-mentioned background technology that the existing fatigue loading test device for the main propeller-hub connector is mainly used for the fatigue life assessment of the third-generation rotor represented by the spherical flexible propeller-hub connector. For the newly developed rigid rotor The above-mentioned existing fatigue loading test device is not applicable.

[0053] However, in the fatigue test, it is necessary to simulate the real boundary conditions of the rigid main rotor hub connection during flight, and apply loads such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com