Material smashing and stirring device with abnormal smell treatment function based on organic fertilizer processing

A technology for odor treatment and organic fertilizer, applied in grain treatment, disperse particle separation, chemical instruments and methods, etc., can solve problems such as adverse environmental impact, scattering, and difficulty in achieving pulverization, preventing interference, ensuring utilization, High crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

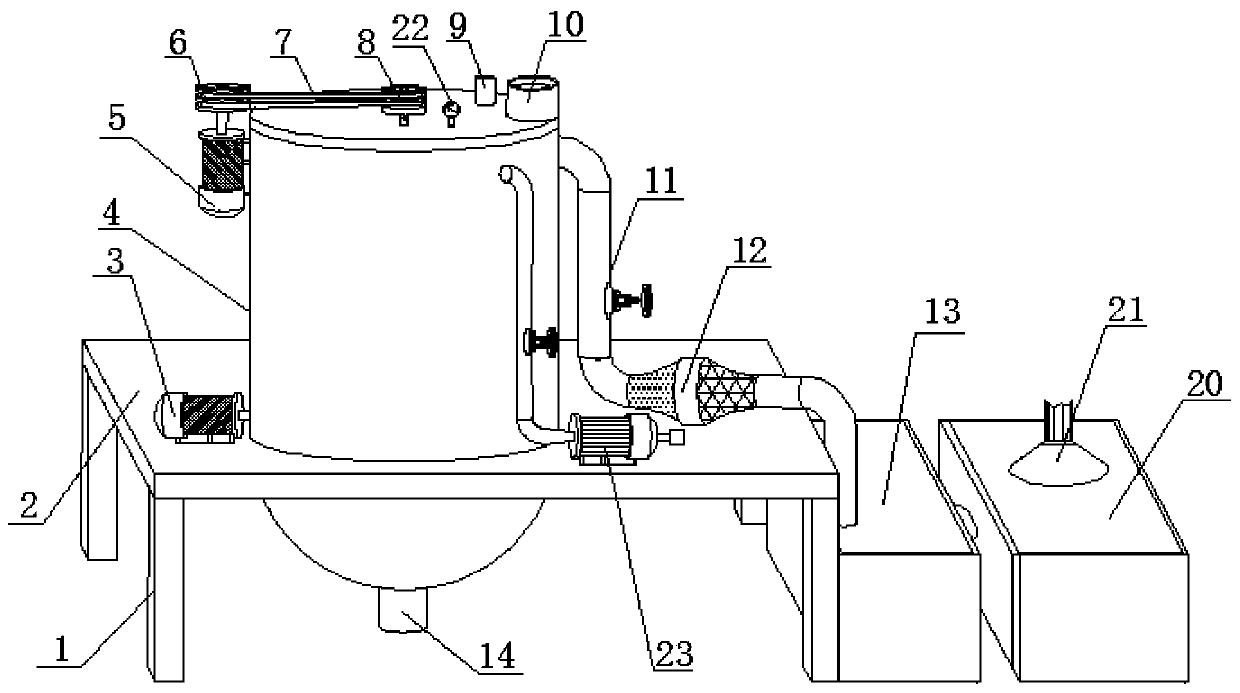

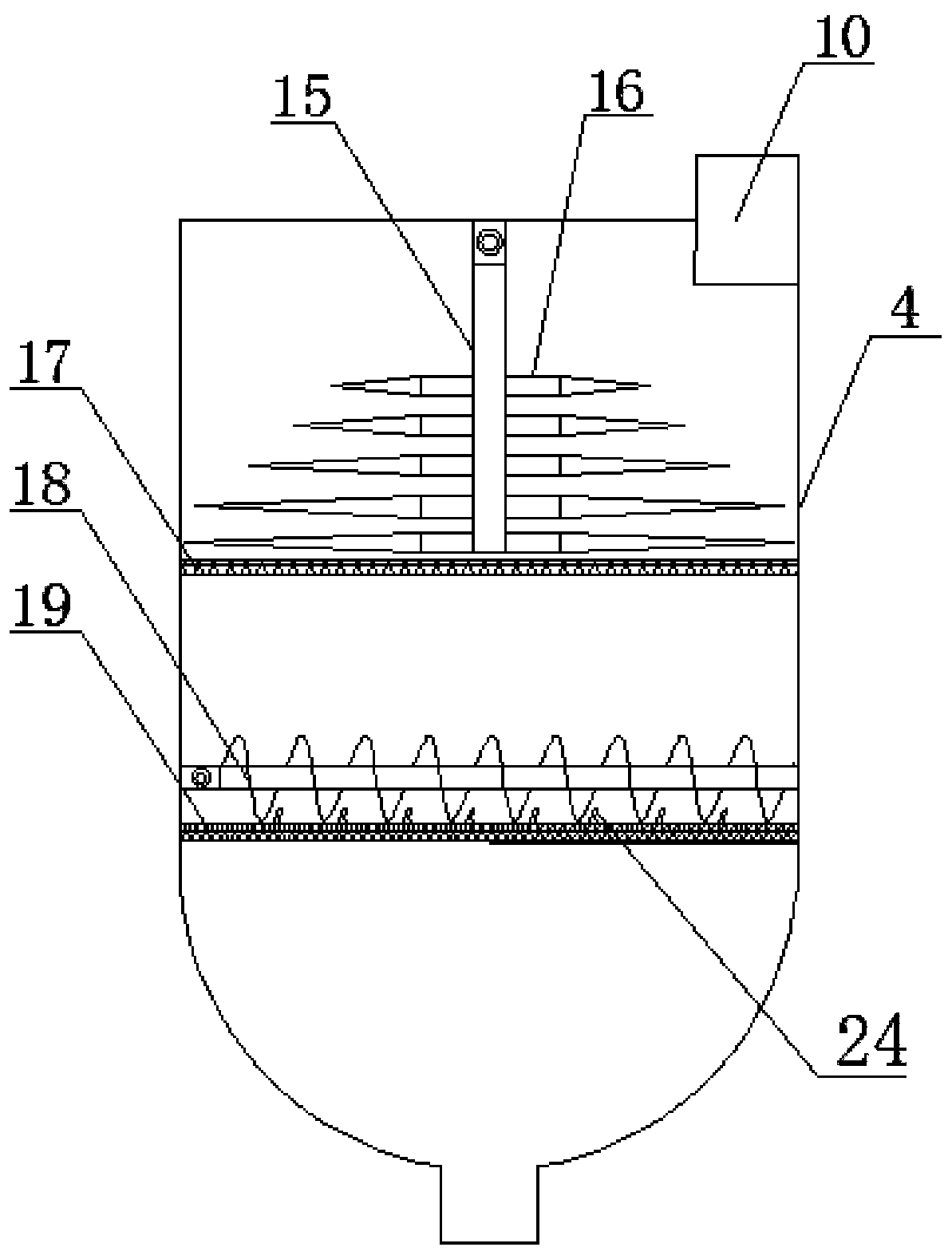

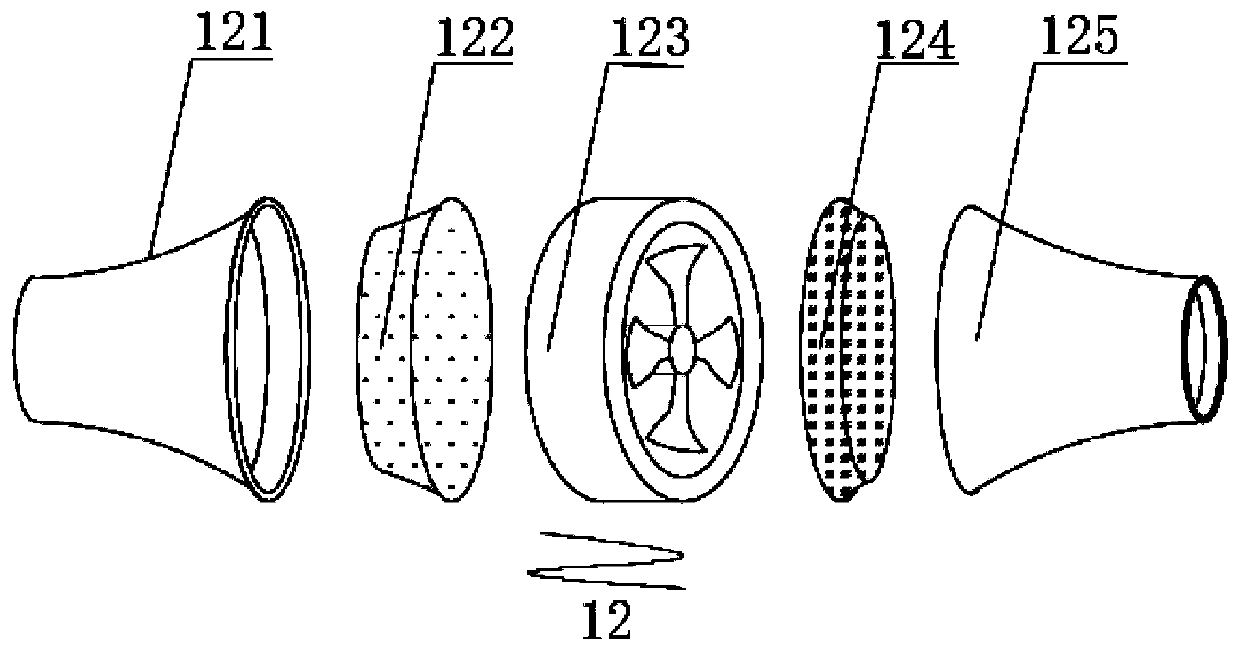

[0021] see Figure 1~3 , in an embodiment of the present invention, a material crushing and stirring device with odor treatment based on organic fertilizer processing includes a tank body 4, a crushing mechanism, an odor treatment mechanism and an air pump 23, wherein the tank body 4 is a sealed structure , the tank body is provided with the crushing mechanism, and the odor treatment mechanism and the air pump are also connected to the tank body; it is characterized in that, before the material is crushed, the air pump 23 first The tank body is subjected to air extraction treatment so that a certain negative pressure is formed in the tank body relative to the external environment, and then the materials in the tank body are crushed under negative pressure. Pressure gauge (22).

[0022] In this embodiment, before the material is pulverized, the pressure inside the tank is 65%-85% of the external atmospheric pressure.

[0023] As a preferred embodiment, the crushing mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com