UHPC (Ultra High Performance Concrete) material for reinforcing existing whole rubble wall and reinforcing method thereof

A technology for rubble and walls, which is applied in the field of strengthening UHPC materials for existing whole rubble walls and its reinforcement field. It can solve the problems of low strength, severe weathering, and insufficient fullness of mortar, etc., and achieve improved earthquake resistance and good fullness. , Increase the effect of mobility and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

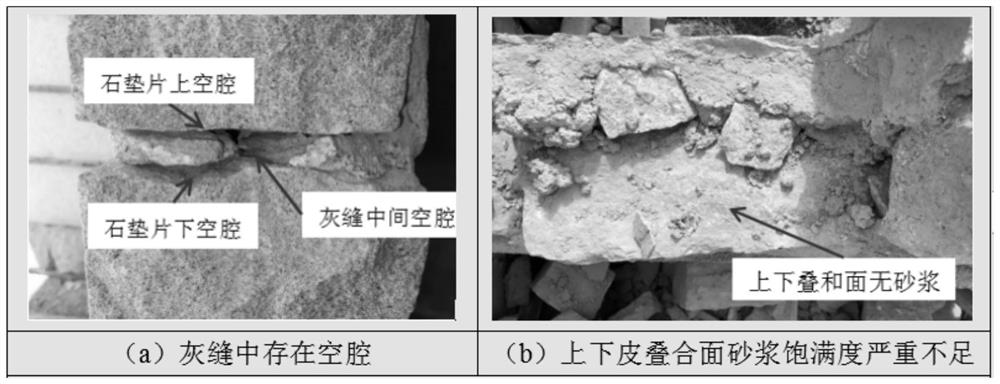

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This example provides a reinforcement method for existing solid stone walls, including the following steps:

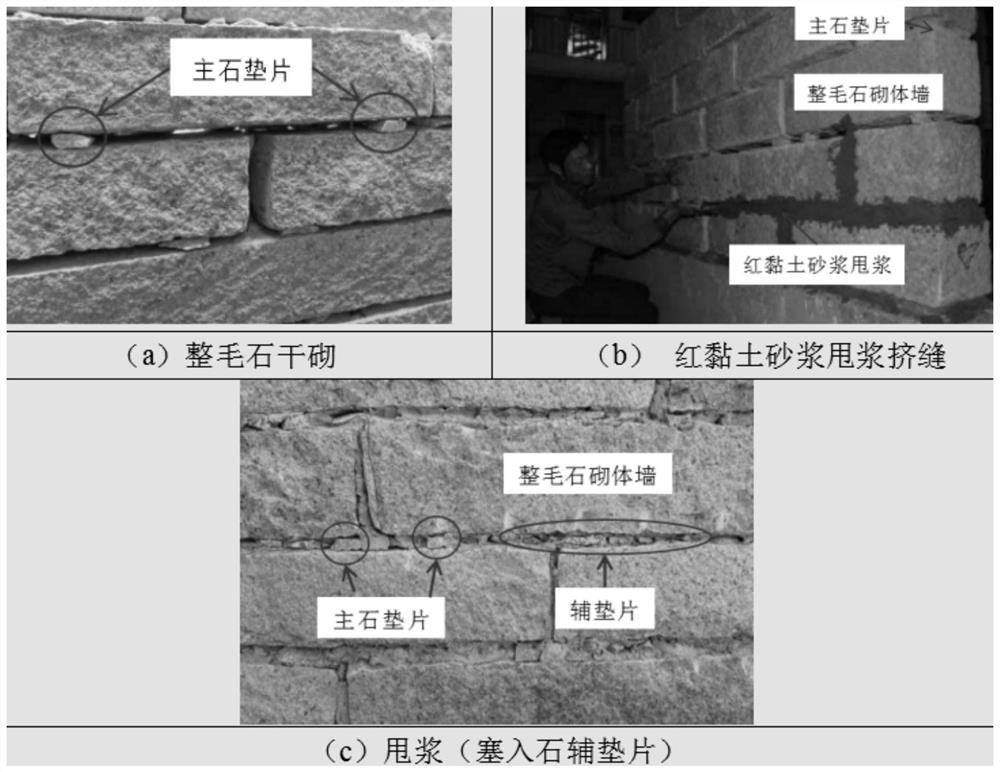

[0045] Step (1): Carry out pretreatment on the existing solid stone wall to be reinforced, including: determine the position of the main gasket, protect the main gasket, and use a chisel) to remove some auxiliary stone gaskets (keep the auxiliary stone gaskets that are difficult to remove ), take out part of the laterite mortar in the ash joint; clean up the dust in the ash joint, and apply a layer of cement slurry on the surface of the wall to be reinforced to enhance the interface bonding performance between the wall and the reinforced surface;

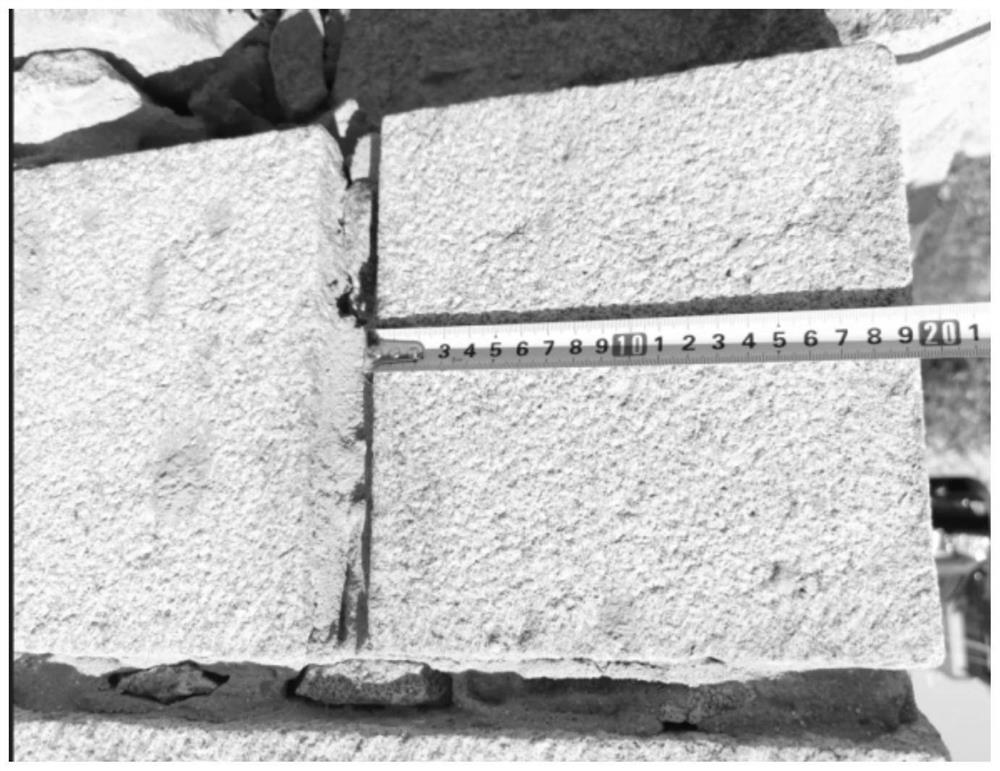

[0046] Step (2): Use the steel bar binding method to tighten and reinforce the existing solid stone wall pretreated in step (1) in a horizontal and vertical manner; the specific process is: horizontally and vertically Tighten and reinforce. Use steel bars (15mm in diameter) to pass through the mortar joints of the wa...

Embodiment 2

[0053] This example provides a method for strengthening the existing solid stone wall. The difference from Example 1 is that the UHPC material used for strengthening the existing solid stone wall includes: Portland cement 550kg / m 3 , white silica fume 200kg / m 3 , limestone powder 530kg / m 3 , Quartz sand 735kg / m 3 , iron ore tailings particles 75kg / m 3 , pumice particles 60kg / m 3 , polycarboxylate water reducing agent 30kg / m 3 , water 255kg / m 3 and POM fiber 25kg / m 3 ; The rest of the steps and parameters are the same.

Embodiment 3

[0055] This example provides a method for strengthening the existing solid stone wall. The difference from Example 1 is that the UHPC material used for strengthening the existing solid stone wall includes: Portland cement 600kg / m 3 , white silica fume 180kg / m 3 , limestone powder 510kg / m 3 , Quartz sand 715kg / m 3 , iron ore tailings particles 60kg / m 3 , pumice particles 50kg / m 3 , polycarboxylate water reducer 15kg / m 3 , water 230kg / m 3 and POM fiber 35kg / m 3 ; The rest of the steps and parameters are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com