Industrial steam cleaning equipment

A technology for cleaning equipment and steam, used in steam generation, steam boilers, steam boiler accessories, etc., can solve problems such as being unsuitable for large-scale promotion, long initial steam output time, and low energy utilization rate, to improve energy utilization rate, The effect of high energy utilization and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

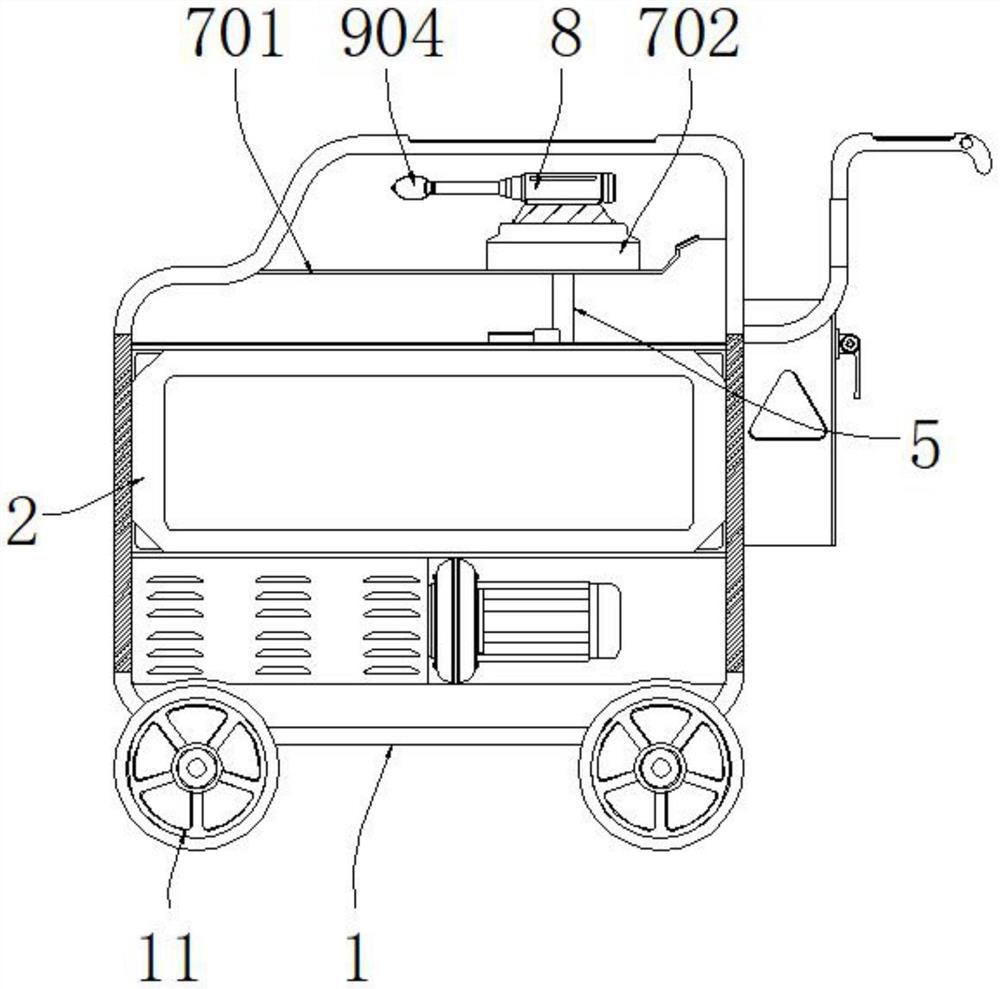

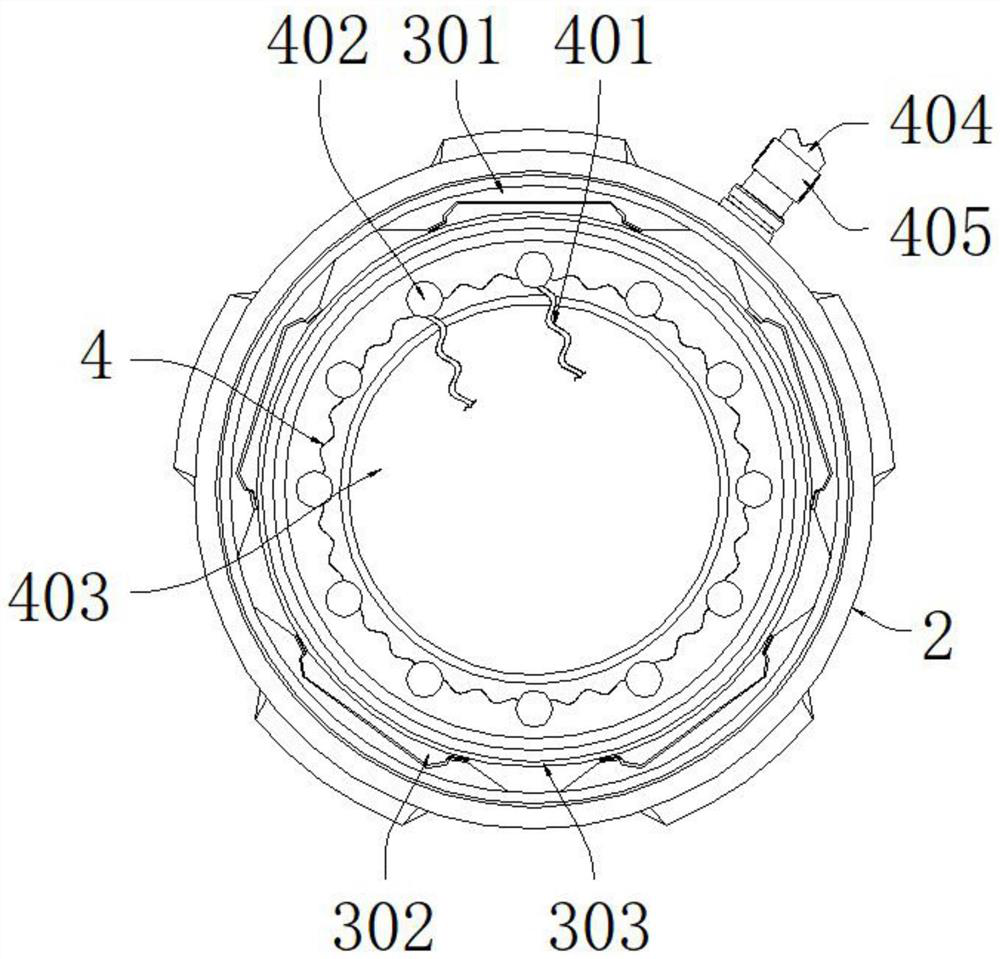

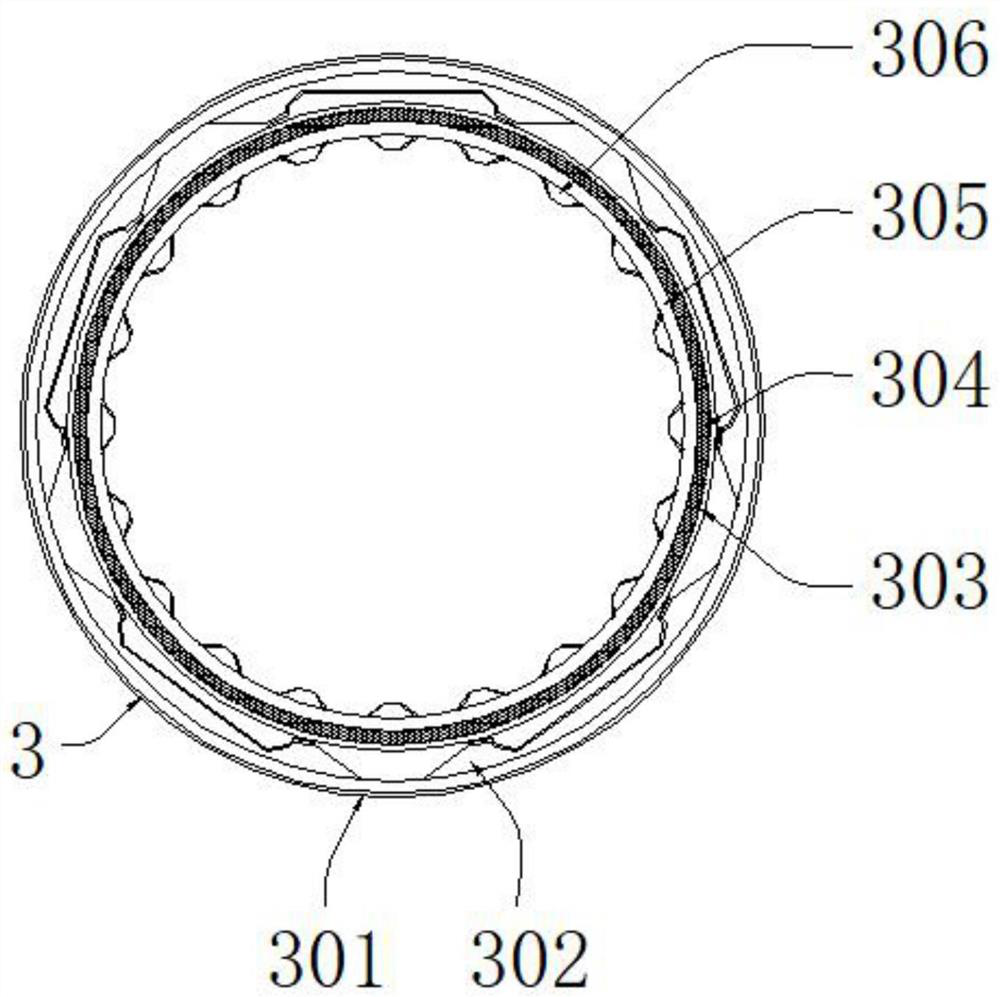

[0029] see Figure 1-7 , the present invention provides a technical solution: an industrial steam cleaning equipment, including a vehicle frame 1 and a limit assembly 7, a moving wheel 11 is installed at the bottom of the vehicle frame 1, and a steam box 2 is installed in the middle of the vehicle frame 1, and the steam box 2 The inner wall is provided with a thermal insulation component 3, and the inner side of the thermal insulation component 3 is provided with a steam adding component 4, and one side of the steam adding component 4 is connected with a conduit 5, and a winding component 6 is arranged outside the conduit 5, and the steam component 4 includes an electric cable 401, High-frequency induction electric heating steam generator 402, water storage metal tank 403, water inlet 404 and filter box 405, the output end of energized cable 401 is connected with high-frequency induction electric heating steam generator 402, and high-frequency induction electric heating A wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com