Dolomite-molybdenum trioxide composite catalyst for preparing acrolein through glycerol dehydration and preparation method of dolomite-molybdenum trioxide composite catalyst

A technology of composite catalyst and dolomite, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., to achieve the effect of low price, simple process equipment and good technical achievements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

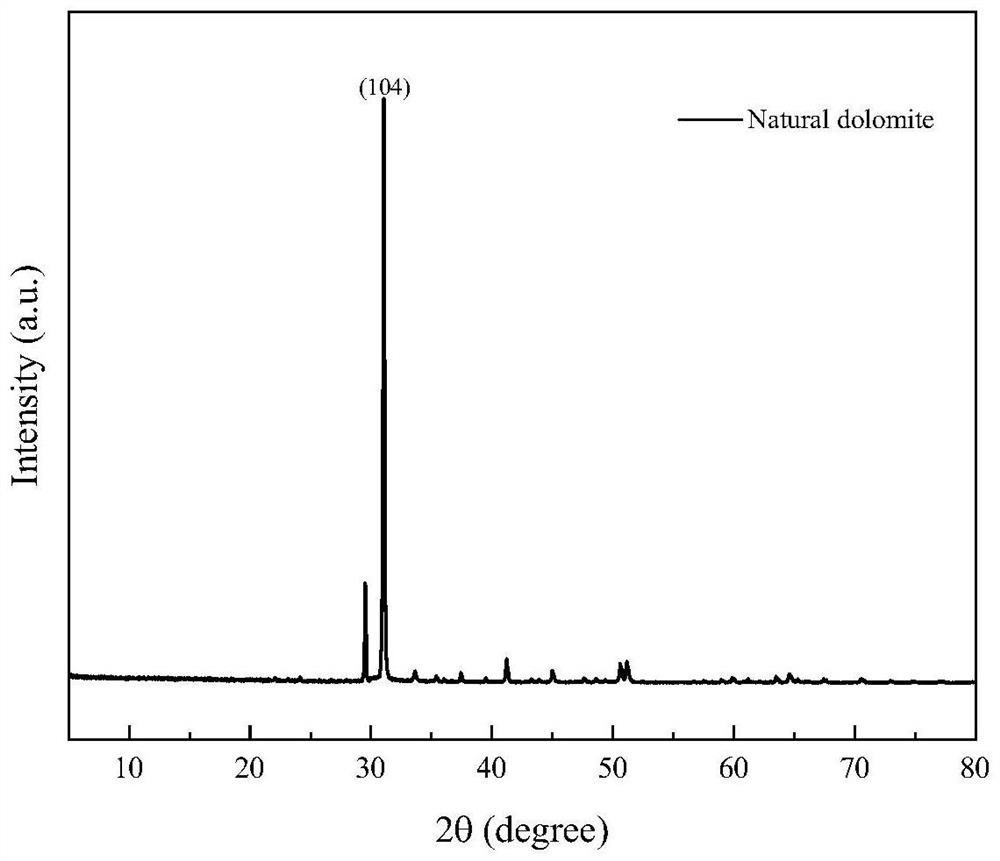

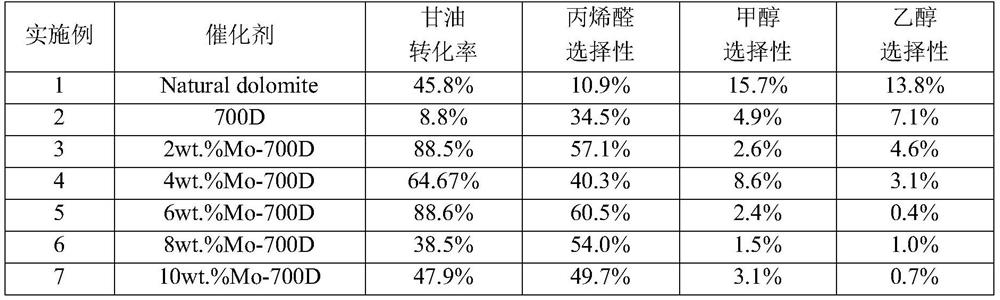

[0034] 20 g of natural dolomite, grinding 60-80 mesh, washed with ethanol, then placed in an oven at 80 ° C for 4 hours to dry it, to obtain a dolomite catalyst, remember to Natural Dolomite.

Embodiment 2

[0036] 20g of 20 g of natural dolomite, ground to 60-80 mesh, washed with ethanol, then put it in an oven at 80 ° C to dry it, and the dried dolomite particles were put into the muffle furnace. Under the 5 ° C / min heating procedure, 700 calcined at 700 ° C for 4 h, resulting in calcination of dolomite, and remembered 700D.

Embodiment 3

[0038] 20g of 20 g of natural dolomite, ground to 60-80 mesh, washed with ethanol, then put it in an oven at 80 ° C to dry it, and the dried dolomite particles were put into the muffle furnace. Under the 5 ° C / min heating procedure, 700 ° C is calcined at 700 to obtain calcined dolomite. Accurately, 0.1000 g of four hydrated molybdate is placed in a 50 ml beaker, add 10 ml of deionized water, stirring it completely dissolved with glass rod, then weighing 4 g is calcined at 700 ° C, added to the above solution, mixed After stirring for 4 h on a magnetic stirrer, stirring at a rate of 300r / min, stirred after 24 h, and then placed in an oven at 80 ° C for 12 h, and finally, the dried sample was placed in a muffle, calcined at 700 ° C. , Temperature rise procedure 10 ° C / min, calcined for 4 h, obtained Dolomite-MOO 3 Composite catalysts contain 2 wt.% MOO 3 Remember 2 wt.% MO-700D.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap