Middle-high voltage circuit breaker capable of expelling products between isolated contacts

A technology for isolating contacts and products, which is applied to circuit breaker parts, circuit breaker contacts, protective switch operation/release mechanisms, etc., which can solve the problems of metal oxidation and hardening on the surface of contacts, high-temperature fires in circuits, and shortened service life, etc. problem, to achieve the effect of reducing the induced current, avoiding splashing, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] use Figure 1-Figure 9 A medium and high voltage circuit breaker with the drive-off of products between isolation contacts according to an embodiment of the present invention is described as follows.

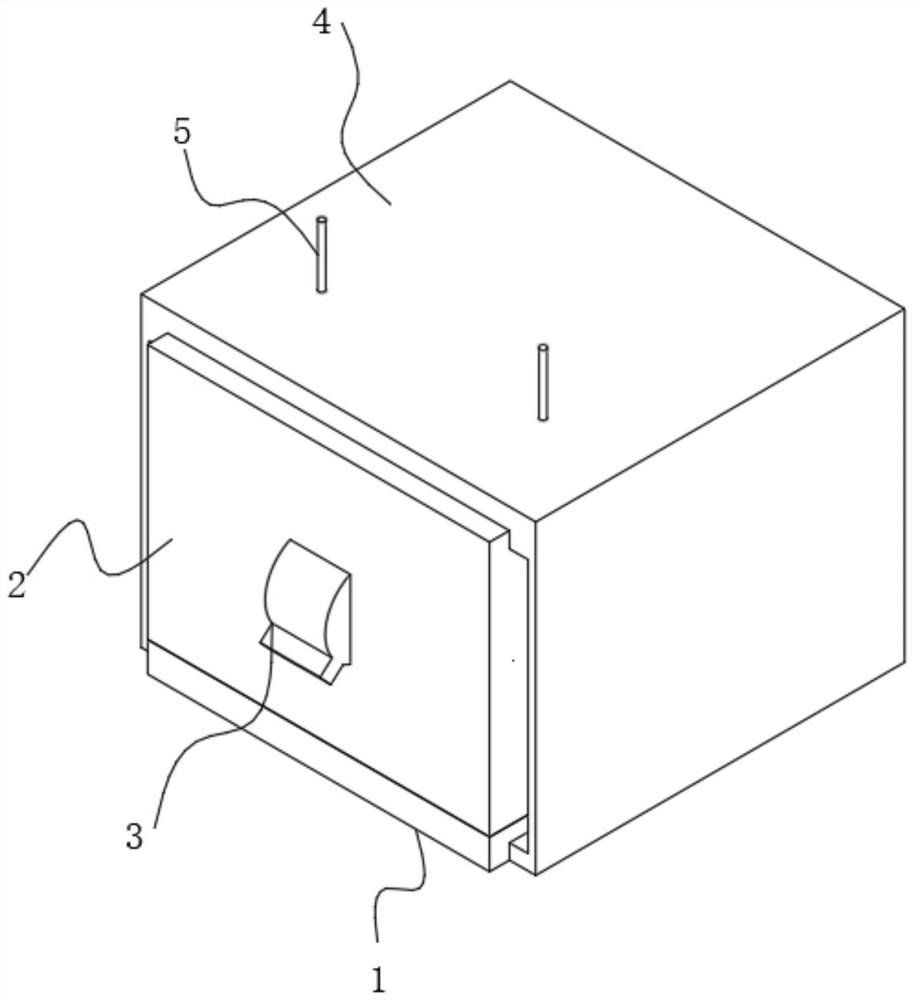

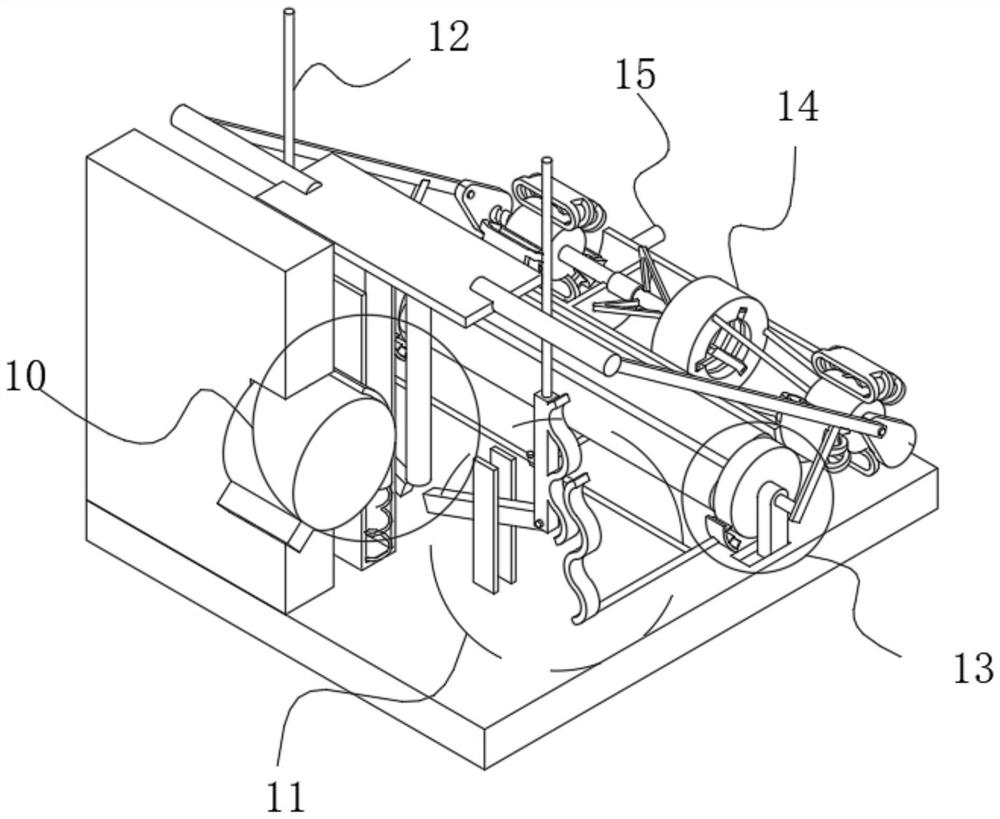

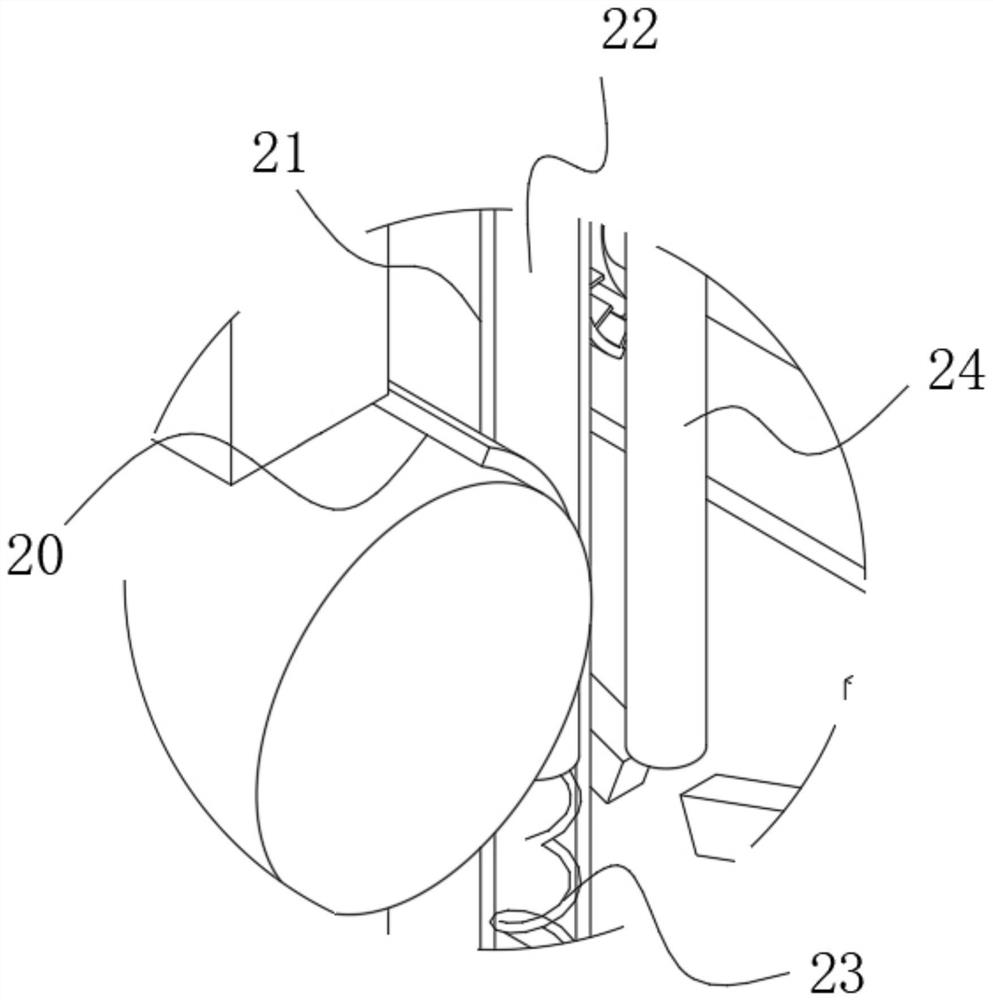

[0028] Such as Figure 1-Figure 9 As shown in the present invention, a medium and high voltage circuit breaker with the drive-off of products between isolated contacts includes a bottom plate 1; the upper surface of the bottom plate 1 is fixedly connected with a front cover 2, and the inner surface of the front cover 2 is rotatably connected with a Adjust the switch 3, the back of the front cover 2 is fixedly connected with the cover plate 4, the upper surface of the cover plate 4 is fixedly connected with the outlet wire 5, the bottom of the outlet wire 5 is provided with an adjustment mechanism 10, and the adjustment mechanism 10 is located inside the cover plate 4, The back side of the adjustment mechanism 10 is movably connected with a secondary closing mechanism 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com