Decontamination method for radioactive nuclear waste metal

A radioactive nuclear waste and radioactive technology, which is applied in the field of decontamination of radioactive nuclear waste metals, can solve problems such as the inability to meet the minimization of radioactive waste, and achieve the effects of small wear, reduced radiation, and short circulation paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

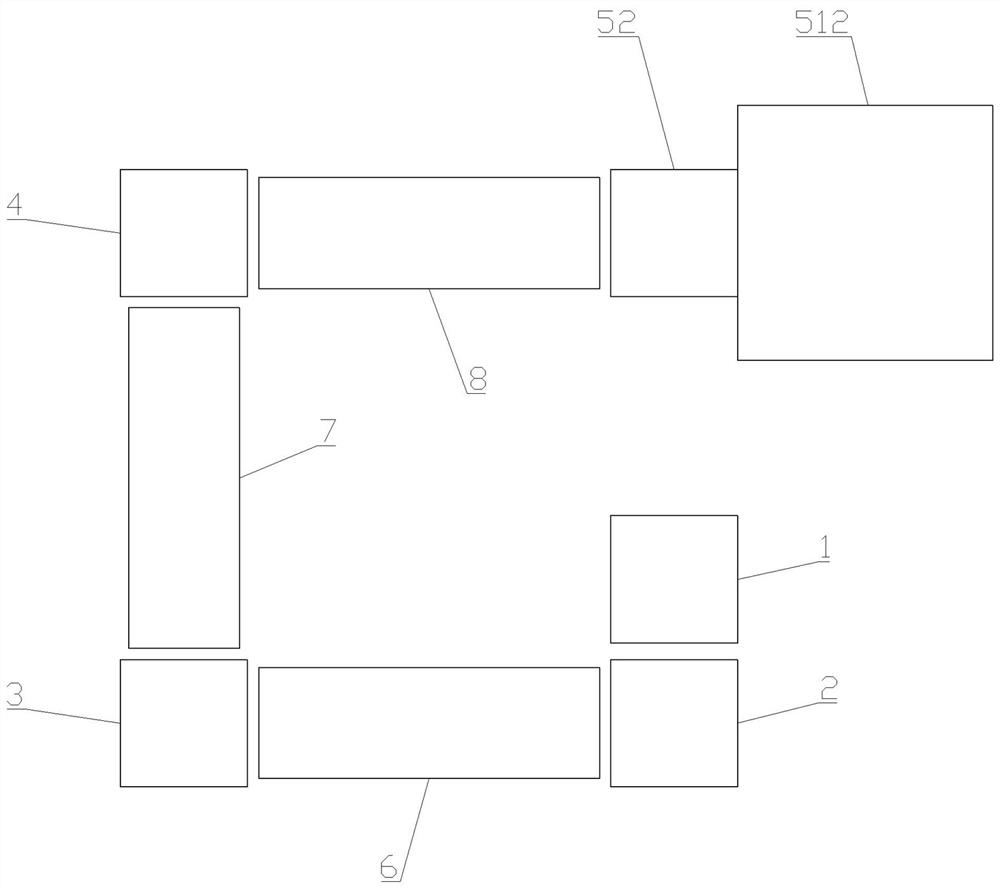

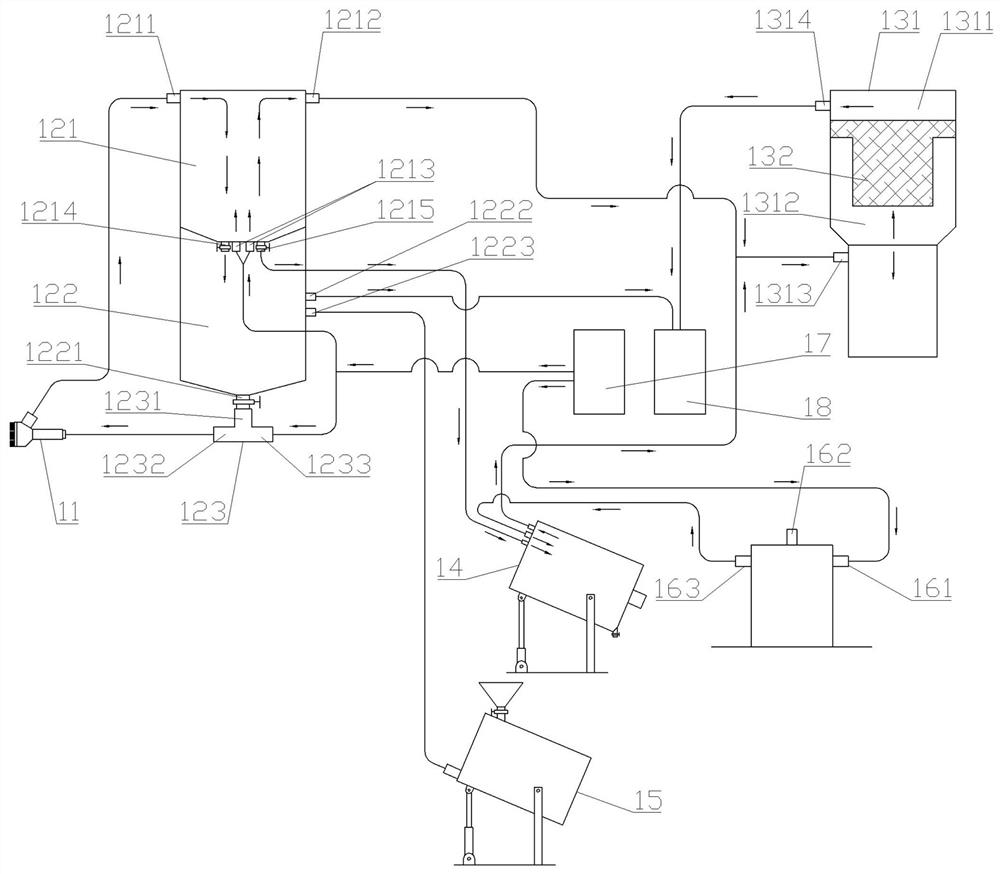

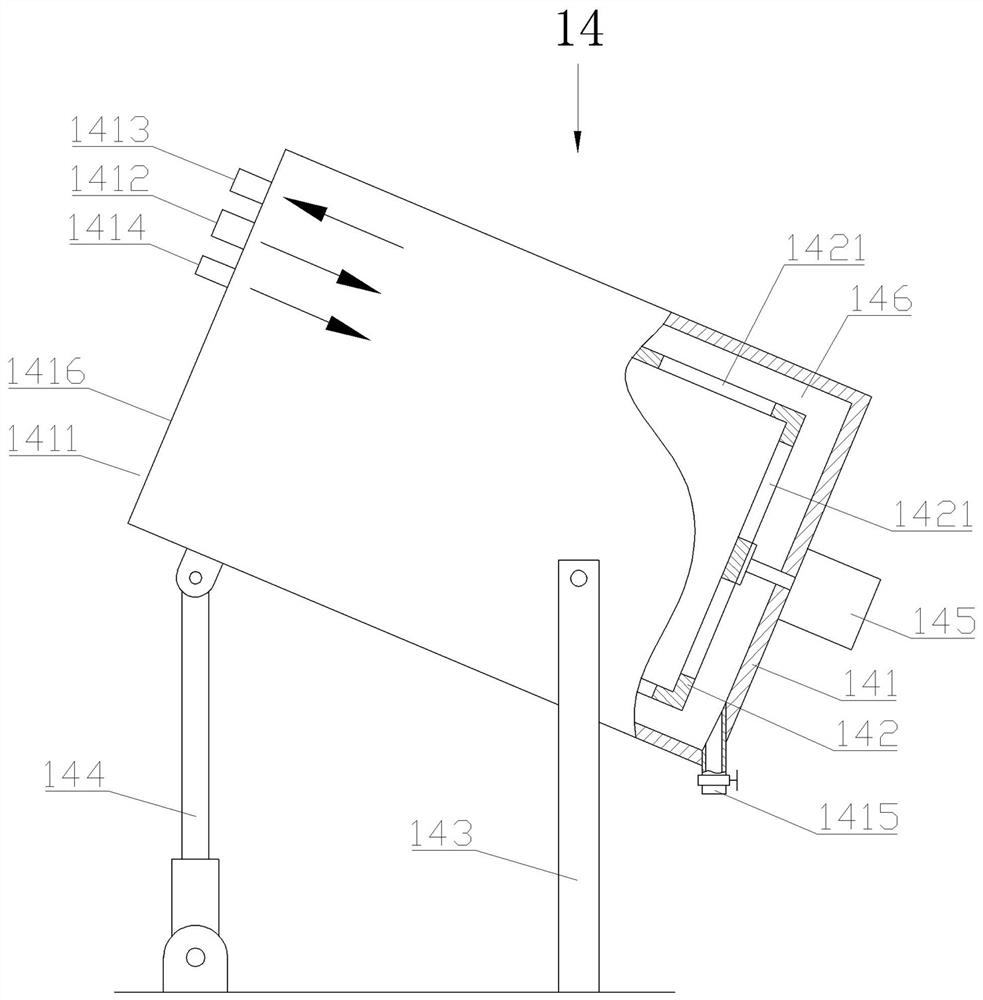

[0141] like Figure 1-12 As shown, the decontamination system for radioactive nuclear waste metal is used for the decontamination of radioactive nuclear waste metal, which includes shot peening decontamination device 1, metal cutting machine 2, metal shredder 3, metal compression baler 4 and metal smelting Feeding assembly.

[0142] The metal shredder 3, the metal compression baler 4 and the metal smelting and feeding assembly are sequentially used in the process of radioactive decontamination of nuclear waste metal. The shot peening decontamination device 1 and the metal cutting machine 2 are used consecutively in the nuclear waste metal decontamination process (continuous use does not limit the sequence of use, it can be cut by the metal cutting machine 2 first, and then decontaminated by the shot blasting decontamination device 1 Dirt, it can also be decontaminated by the shot blasting decontamination device first, and then cut by the metal cutting machine 2). And, the us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com