Flue fan control method based on dynamic decarburization rate of molten pool of combined blown converter

A control method and technology of molten pool, which are applied in the direction of improving process efficiency, steel manufacturing process, manufacturing converter, etc., can solve the problems of less recovery amount, matching of decarburization rate of molten pool, unfavorable improvement of calorific value of recovered gas, etc. , to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

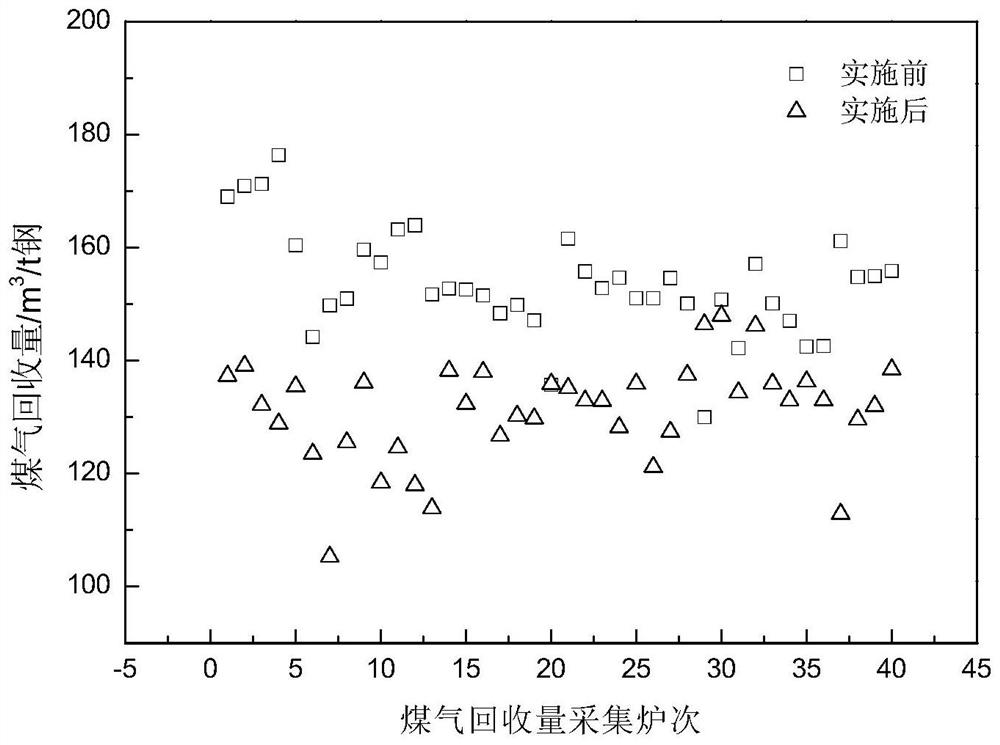

[0061] The invention provides a flue fan control method based on the dynamic decarburization rate of the double blowing converter molten pool. The method first collects blowing parameters and measured data, and establishes the relationship between the molten pool motion characteristics, the decarburization rate, and the amount of flue gas generated. , during the normal blowing process of the converter, combined with the linkage matching of the flue system and the adjustment characteristics of the fan, the micro-positive pressure of the converter mouth is precisely controlled throughout the smelting process, reducing the air intake of the converter mouth, reducing the air combustion coefficient of the flue gas, and improving recovery Gas quality (calorific value).

[0062] Processing step of the present invention is as follows:

[0063] a. Collect the equipment parameters, process parameters, and raw and auxiliary material parameters of the re-blowing converter to establish a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com