Electrochemical crosslinking type high-performance electrochromic film as well as preparation method and application thereof

An electrochromic, high-performance technology, applied in hybrid capacitor electrolytes, optics, nonlinear optics, etc., can solve the problems of difficult material synthesis and rising raw material production costs, and achieve excellent photoelectric activity, thermal stability, and good controllability , The effect of simple film making method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

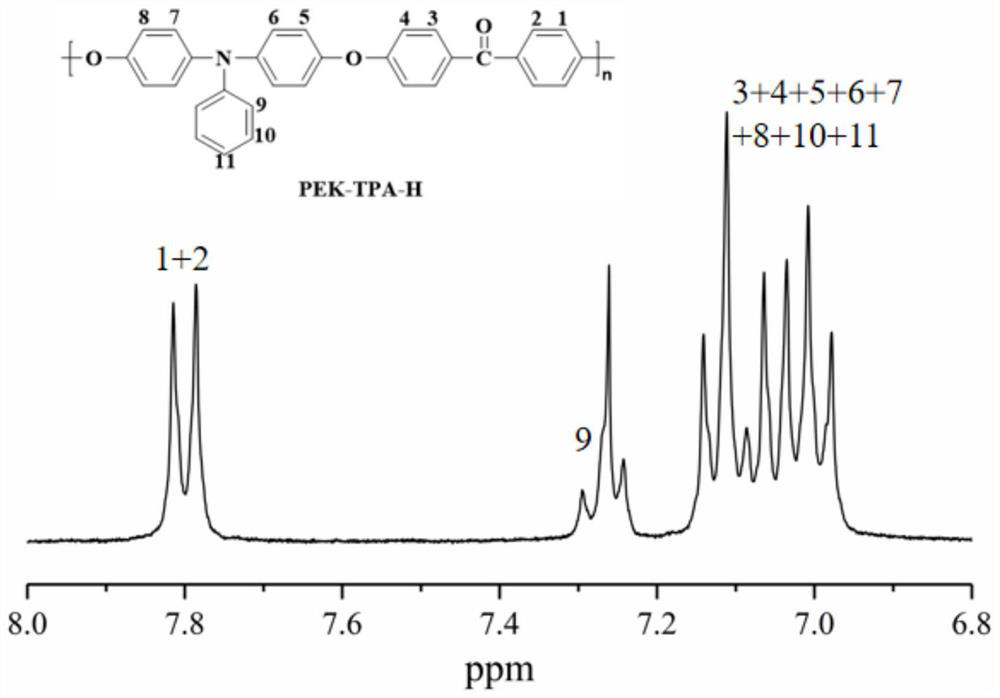

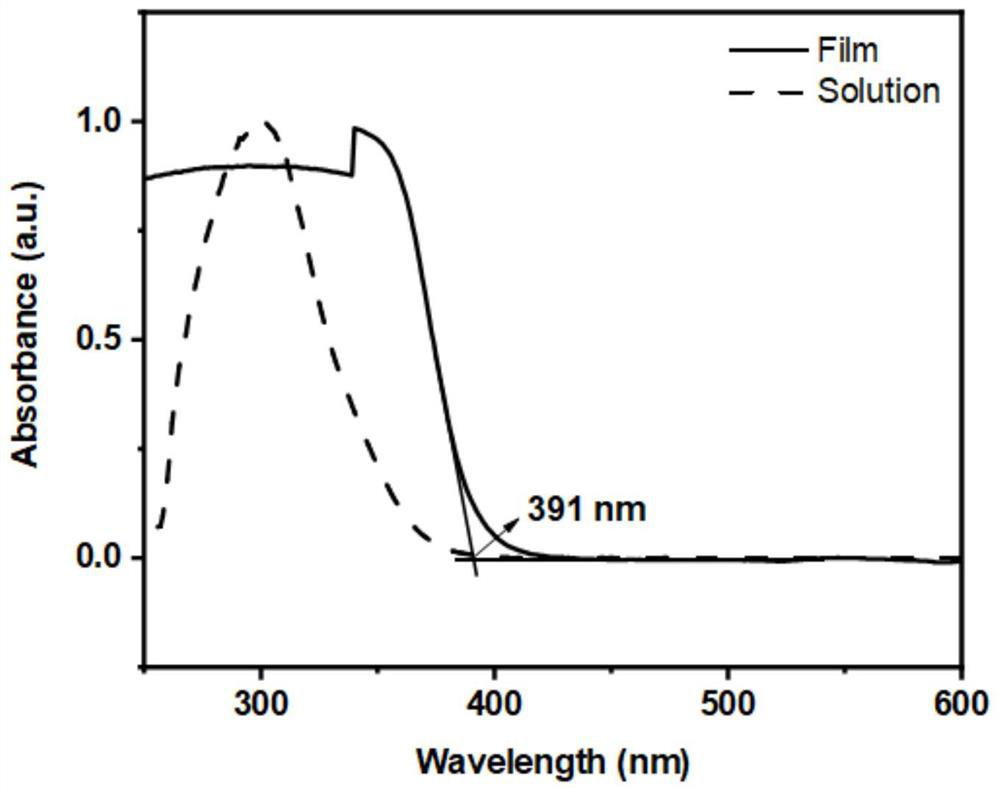

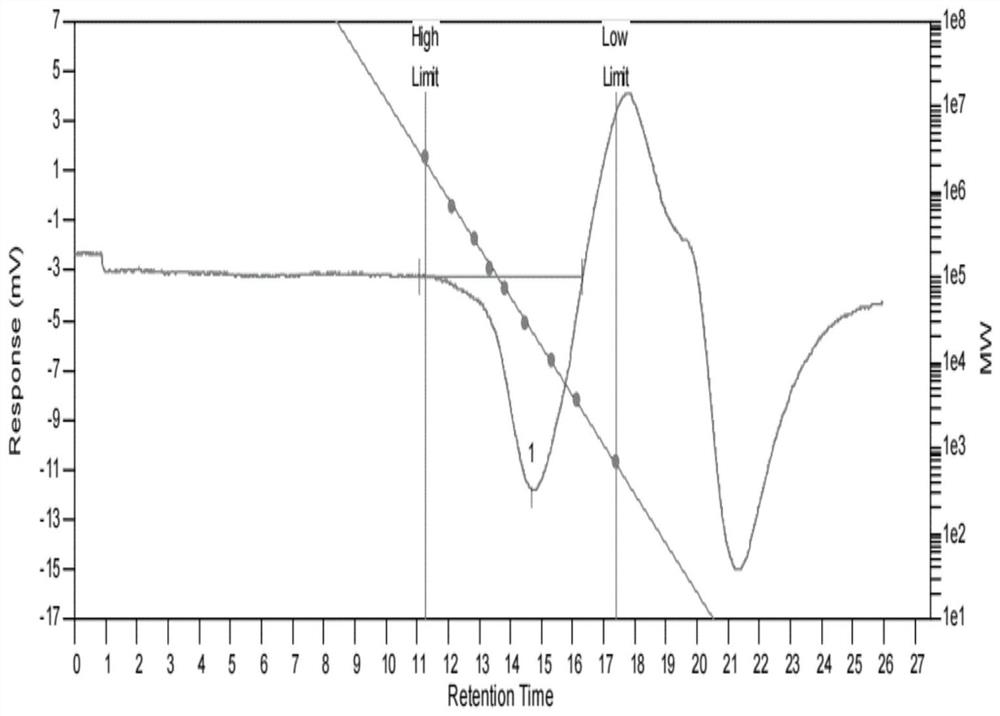

Embodiment 1

[0092]Example 1: Polymer P1 is obtained by polymerizing the precursor monomer 4,4'-(phenylureadiyl)biphenol and 4,4'-difluorobenzophenone. The specific operation is as follows: commercially available triphenylamine Add the monomer 4,4'-(phenylureadiyl)biphenol, 4,4'-difluorobenzophenone, potassium carbonate, sulfolane and toluene into the three-necked flask in a certain proportion, install the thermometer, tetrafluoroethylene Stirring paddle and oil-water separator and condenser tube. Toluene is selected as the oil-water separation reagent, and toluene is added to the separator until it is flush with the outlet of the branch pipe. Under the condition of continuously feeding argon gas protection, the temperature of the oil bath is controlled to be 145 degrees Celsius, and the mixture is heated and stirred. Start timing when the liquid in the oil-water separator has obvious droplets or becomes turbid, and take water for 3 hours to remove the water in the flask. When the two-ph...

Embodiment 2

[0101] Example 2: Preparation of a cross-linked polymer film by cyclic voltammetry: a standard three-electrode system is used, that is, ITO spin-coated with a polymer film is used as a working electrode; a silver / silver ion electrode is used as a reference; a platinum wire is used as a counter electrode. The electrolytic solution is an acetonitrile solution of tetrabutylammonium perchlorate with a concentration of 0.1 mole per liter. The start and stop voltages are 0 volts and 0.8 volts, respectively. Select 500 circles for the number of circles. After electrification, rinse the ITO electrode three times with acetonitrile and water respectively, and then put it into a vacuum drying oven at 120 degrees Celsius for 4 hours to obtain a cross-linked polymer film prepared by cyclic voltammetry.

Embodiment 3

[0102] Example 3: Preparation of cross-linked polymer film by constant voltage method: a standard three-electrode system was used, that is, ITO spin-coated with a polymer film was used as a working electrode; silver / silver ion electrode was used as a reference; platinum wire was used as a counter electrode. The electrolytic solution is an acetonitrile solution of tetrabutylammonium perchlorate with a concentration of 0.1 mole per liter. The voltage selection is 0.8 volts. Select 400 seconds as the power-on time. After energizing, wash the ITO electrode three times with acetonitrile and water respectively, and then put it in a vacuum drying oven at 120 degrees Celsius for 4 hours to obtain a cross-linked polymer film prepared by a constant voltage method.

[0103] Both of the above crosslinking methods can be used Figure 8 The flow representation shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap