A kind of semiconductor core optical fiber preparation method

A technology of semiconductor and core optical fiber, applied in cladding optical fiber, optical waveguide and light guide, etc., can solve the problems of undeveloped multi-combination and multi-structure optical fiber semiconductor devices, single structure, etc., achieve orderly structure, low preparation cost, and process short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

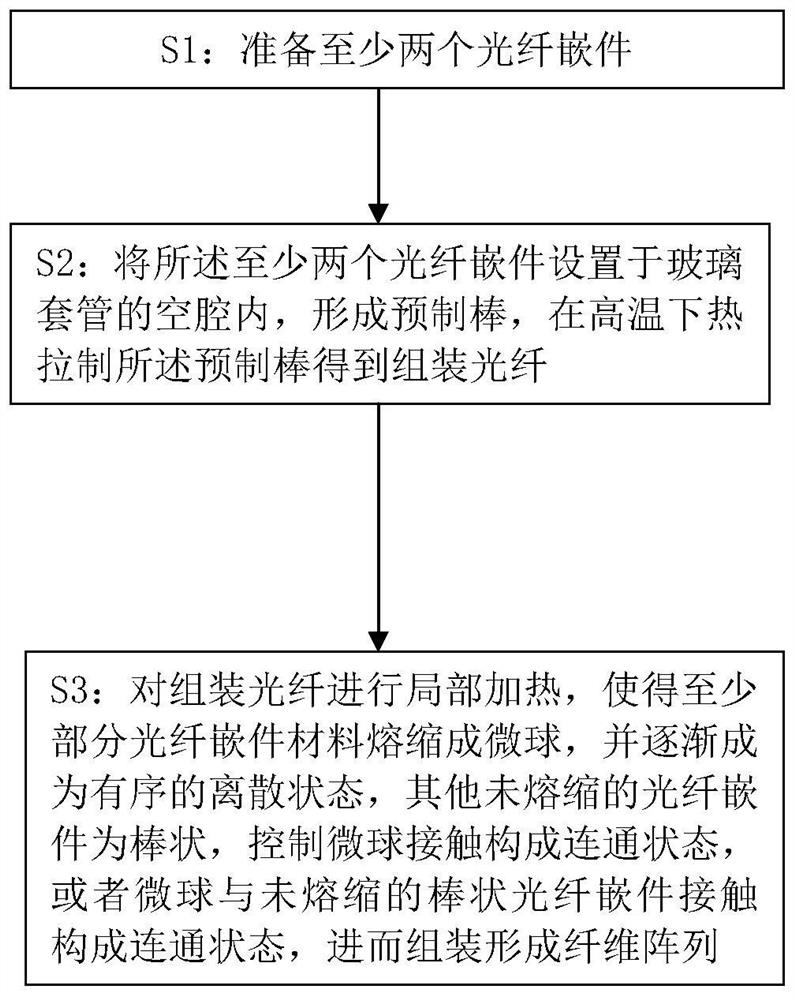

[0065] A method for preparing a semiconductor core optical fiber, comprising the steps of:

[0066] S1: Prepare at least two fiber inserts, the at least two fiber inserts are semiconductor single-core optical fiber, semiconductor material core rod, metal material core rod, composite core rod of multiple metal materials, combination of semiconductor material and metal material at least one of the mandrels;

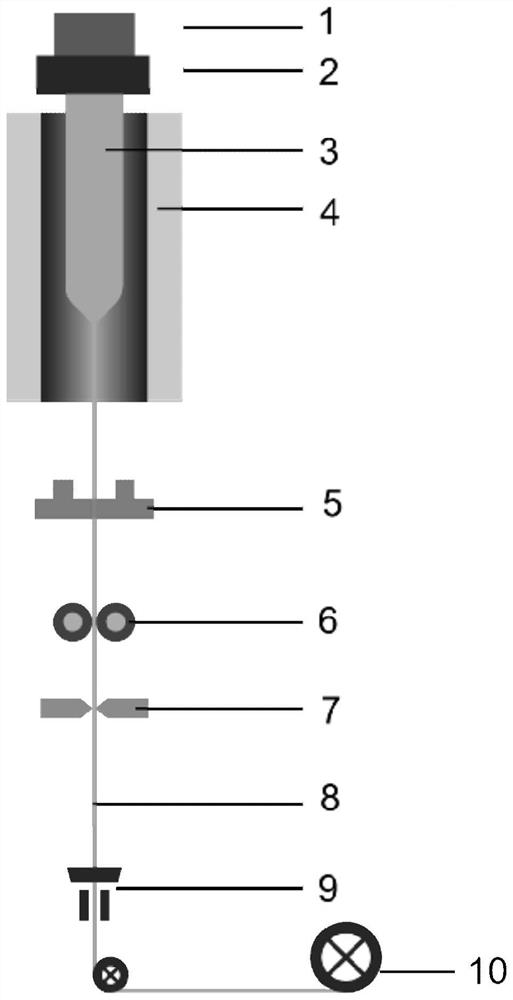

[0067] S2: disposing the at least two optical fiber inserts in the cavity of the glass sleeve to form a preform, and hot drawing the preform at high temperature to obtain an assembled optical fiber;

[0068] S3: Locally heating the assembled optical fiber, so that at least part of the fiber insert material is condensed into microspheres, and gradually becomes an orderly discrete state, and other unmelted fiber inserts are rod-shaped, and the contact of the microspheres is controlled to form a connected state. Or the contact between the microspheres and the unshrunk rod-sha...

Embodiment 1

[0074] Embodiment 1 of the present invention provides a method for preparing an optical fiber, such as Figure 4As shown, the outer layer of the optical fiber is quartz glass, and the inner layer is a Si / Ge double-sphere array structure.

[0075] The preparation method of the optical fiber is specifically as follows:

[0076] S1: Prepare an optical fiber insert, the optical fiber insert in this embodiment is a semiconductor single-core optical fiber, specifically the preparation method is

[0077] Such as Figure 3a , 3b As shown, get the silicon rod 11 and the germanium rod 14 with an outer diameter of 2 mm and a length of 4 cm, two quartz glass rods with an outer diameter of 2 mm and a length of 5 cm, and two quartz tubes with an inner diameter of 2.1 mm, an outer diameter of 40 mm, and a length of 30 cm. Two frosted quartz tubes with an outer diameter of 40mm and an inner diameter of 30mm, after welding the quartz tube and the frosted quartz tube with a flame gun, place ...

Embodiment 2

[0086] Such as Figure 7a , 7b As shown, the assembled optical fiber to be processed in this embodiment has an outer layer of quartz glass and an inner layer of a Si / Ge / Si heterogeneous lateral array structure.

[0087] S1: preparing an optical fiber insert, the optical fiber insert in this embodiment is to prepare a silicon core optical fiber 13 and a germanium core optical fiber 15 by preliminary drawing,

[0088] S2: disposing the at least two optical fiber inserts in the cavity of the glass sleeve to form a preform, and hot drawing at a high temperature to obtain an assembled optical fiber. Specifically, after welding the quartz tube with outer diameter: inner diameter = 11: 5.8mm and the frosted quartz tube with a flame gun, take a quartz glass rod with an outer diameter of 5.7 mm and a length of 5 cm and place it at the lower end of the quartz tube, and use a flame gun to melt the quartz tube. The bottom end is heated and melted. The purpose is to adjust the process p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap