A method for regulating the orientation of liquid crystal molecules through special rod-like molecules or their polymers

A technology of liquid crystal molecules and polymers, applied in liquid crystal materials, chemical instruments and methods, organic chemistry, etc., can solve problems such as complex processes and affect the use of materials, and achieve the effect of simple and easy methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

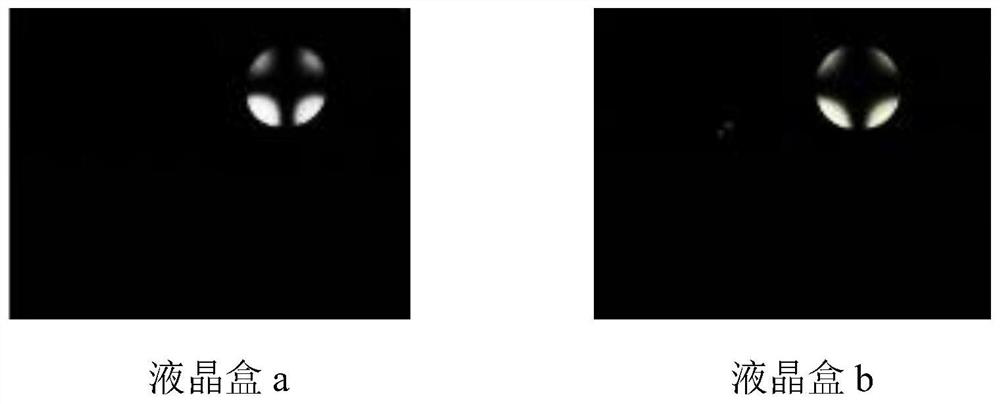

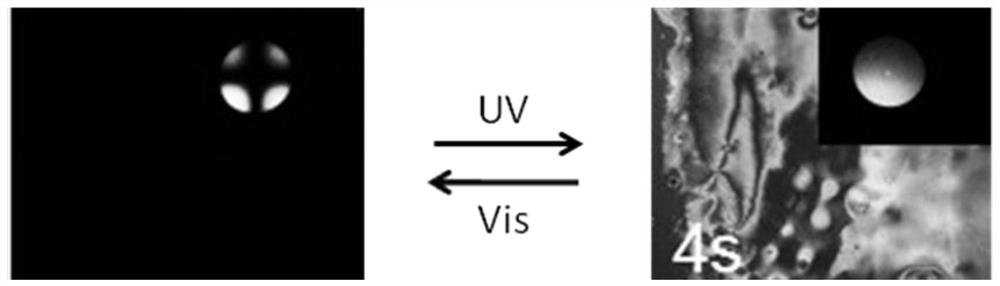

[0037] A method for regulating the alignment of 5CB liquid crystals by special rod-shaped molecules containing azobenzene or polymers thereof, comprising the steps of:

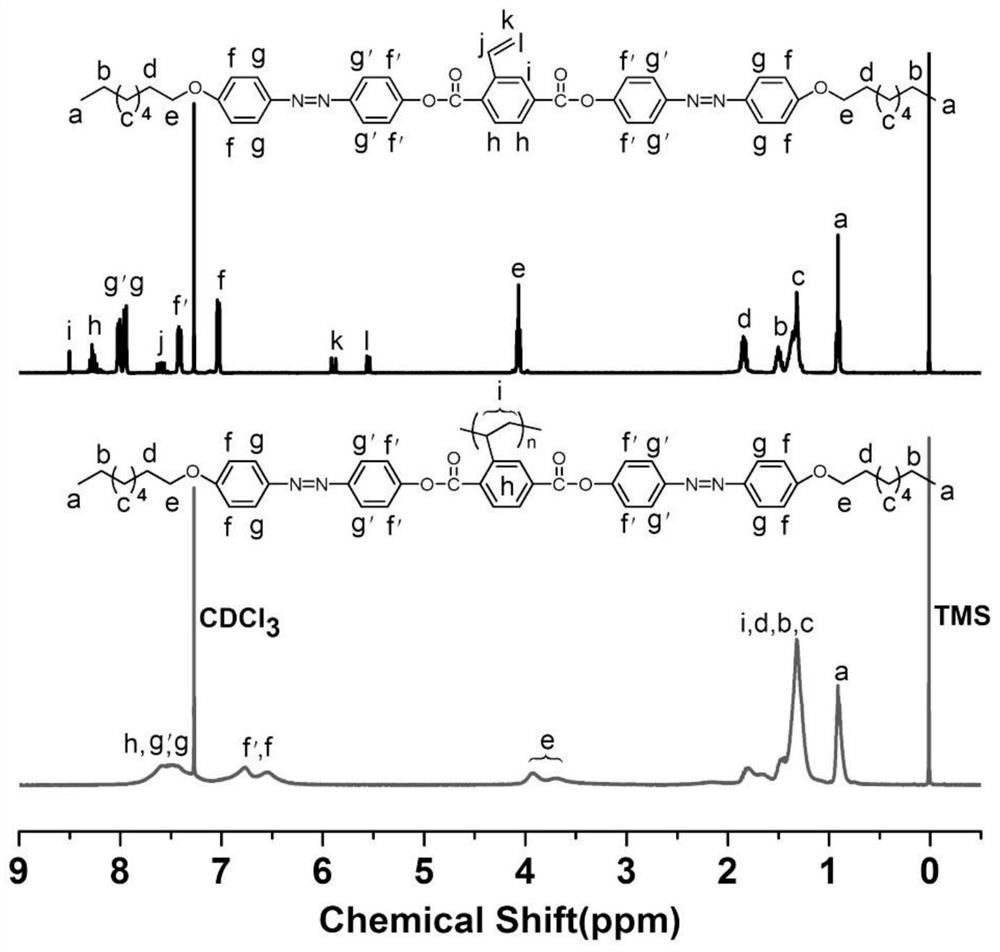

[0038] (1) Preparation of special rod-shaped molecules containing azobenzene and their polymers:

[0039] Raw materials: paracetamol, 1-bromooctane, acetone, anhydrous potassium carbonate, absolute ethanol, sodium hydroxide, potassium nitrite, phenol, hydrochloric acid, terephthalic acid, oxalyl chloride, dichloromethane, tetrahydrofuran ( THF), triethylamine, azobisisobutyronitrile (AIBN), chlorobenzene, dichloromethane.

[0040] Weigh dry raw material vinyl terephthalic acid (1.2g, 7.22mmol), dissolve in 50ml dry dichloromethane and 2ml oxalyl chloride [(COCl) 2 ] in a 100mL round-bottomed flask, placed in a 60°C oil bath, and stirred until clarified. The reaction solution was spin-dried, and then 30 ml of refined tetrahydrofuran was added to obtain an acyl chloride reaction solution, which was set aside. ...

Embodiment 2

[0051] A method for regulating the interval of 5CB liquid crystals through special rod-shaped molecules containing biphenylazo or polymers thereof, comprising the steps of:

[0052] (1) Synthesis of special rod-shaped molecules containing biphenylazo or their polymers:

[0053] Raw materials: 4-(4'-hydroxy)azophenylbiphenol, 1-bromooctane, acetone, anhydrous potassium carbonate, anhydrous ethanol, sodium hydroxide, potassium nitrite, phenol, hydrochloric acid, terephthalic acid, Oxalyl Chloride, Dichloromethane, Tetrahydrofuran (THF), Triethylamine, Azobisisobutyronitrile (AIBN), Chlorobenzene, Dichloromethane.

[0054] Weigh dry raw material vinyl terephthalic acid (1.2g, 7.22mmol), dissolve in 50ml dry dichloromethane and 2ml oxalyl chloride [(COCl) 2 ] in a 100mL round-bottomed flask, placed in a 60°C oil bath, and stirred until clarified. The reaction solution was spin-dried, and then 30 ml of refined tetrahydrofuran was added to obtain an acyl chloride reaction solution...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap