High-safety lifting platform for ship outer wall detection

A lifting platform and safety technology, which is applied in the field of lifting platforms for ship outer wall detection, can solve problems such as easy swing, insufficient height of lifting platforms, low safety of lifting platforms, etc., to achieve increased stability, low manufacturing cost, and improved safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

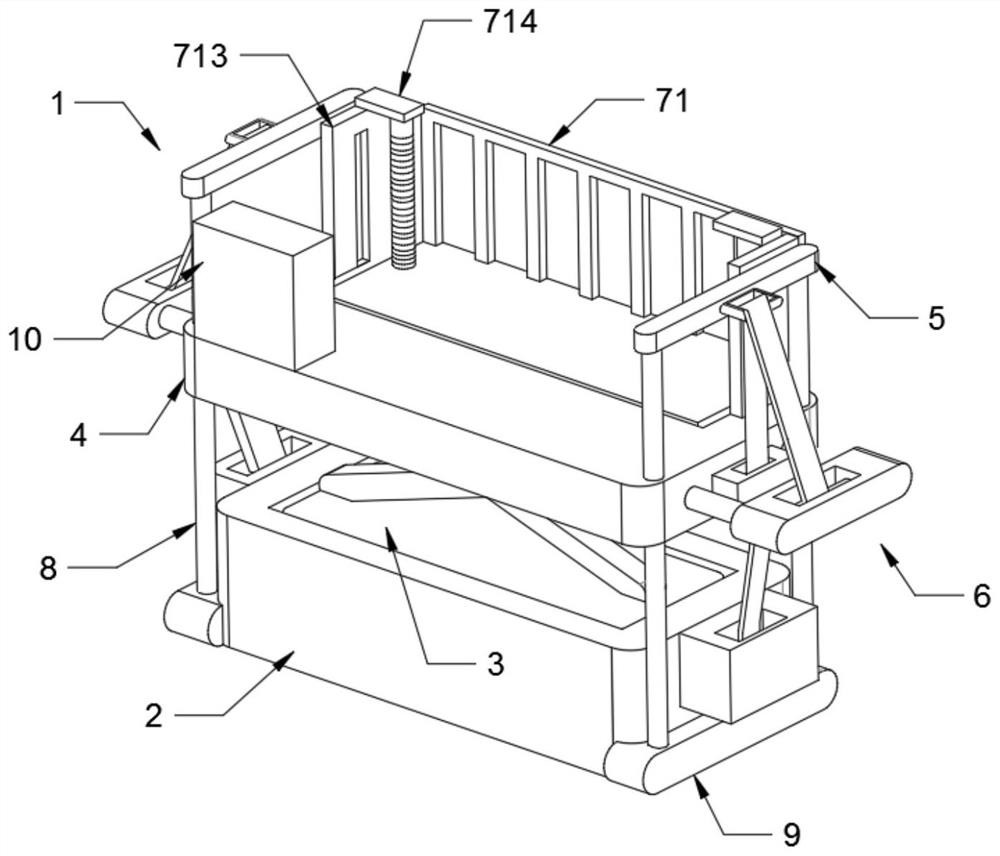

[0028] Refer to attached figure 2 , a highly safe lifting platform for detecting the outer wall of a ship, comprising a lifting device main body 1 and a scissor lift 3, the lifting device main body 1 includes a base 2 for fixedly installing the scissor lift 3, and the lifting device main body 1 also includes The lifting platform 4 fixedly installed on the output end of the scissor lift 3, the base 2 is fixedly installed with a plurality of stabilizing columns 8 running through the lifting platform 4, and the adjacent stabilizing columns 8 are fixedly installed with a maintenance link 5, and the base 2 and the lifting platform are fixedly installed. An auxiliary stabilizing mechanism 6 is provided between both sides of the platform 4, and the auxiliary stabilizing mechanism 6 includes a rope receiving device 61 fixedly installed on the base 2, a first rope receiving platform 62 on the lifting platform 4, a fixed rope platform 63 and a fixed rope receiving platform 63. On the s...

Embodiment 2

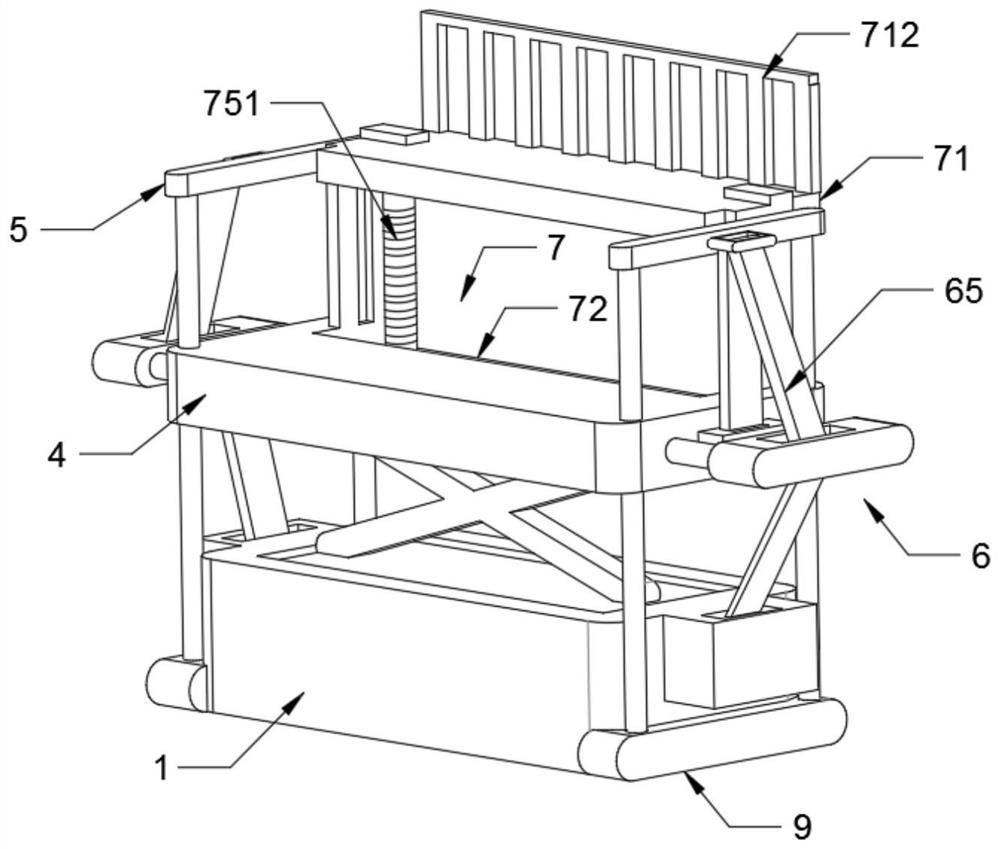

[0032] With reference to the accompanying drawings lifting device main body 1 and base 2, on the basis of Embodiment 1, the auxiliary lifting mechanism 7 includes an auxiliary platform 71 arranged on the lifting platform 4 for lifting, and the auxiliary lifting mechanism 7 also includes a The air outlet assembly 74, the auxiliary lifting mechanism 7 also includes a motor 73 fixedly installed in the lifting platform 4, and the lifting platform 4 also includes two auxiliary driving rollers 76 that are rotatably installed in the lifting platform 4, and the output end of the motor 73 is fixedly installed with Driving roller 731, two auxiliary driving rollers 76 and driving roller 731 are all provided with belt pulley 79, be provided with belt pulley 78 between adjacent belt pulley 79, belt pulley 79 on the driving roller 731 is a double-groove belt pulley, auxiliary driving roller 76 is provided with The driving assembly 75, the driving assembly 75 includes a bevel gear assembly 752 ...

Embodiment 3

[0036] Based on the above-mentioned embodiment one or two, the air outlet assembly 74 includes an installation chamber 741 fixedly installed in the lifting platform 4, and the air outlet assembly 74 also includes two air outlet slots 742 provided on the elevator platform 4, and the installation chamber 741 rotates A rotating rod 743 is installed, and one end of the rotating rod 743 is fixedly connected with the driving roller 731. The driving roller 731 runs through the installation chamber 741, and two auxiliary rotating rods 744 respectively located in the air outlet groove 742 are installed in the air outlet assembly 74 for auxiliary rotation. The fan blade 745 located in the air outlet slot 742 is fixedly installed on the rotating rod 744. In this embodiment, a filter screen is fixedly installed outside the air outlet slot 742, which can prevent foreign matter from entering the air outlet assembly 74 and protect the air outlet assembly. The safety of wind assembly 74, drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com