High-temperature-resistant holographic information alumite material for cloth cover hot stamping and preparation method and application thereof

A holographic information and anodized aluminum technology, which is applied in the field of high-temperature resistant holographic information anodized aluminum materials for cloth hot stamping and its preparation, can solve the problems of blurred images and texts, lack of hot stamping patterns, exposed bottom, etc., and achieves clear and crisp details. The hot stamping pattern is clear and the reflection brightness is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The holographic information anodized aluminum material of this embodiment is prepared through the following steps:

[0044] (1) Coating the liquid raw material of the release layer on the clean PET substrate layer by a coating machine, drying to form the release layer;

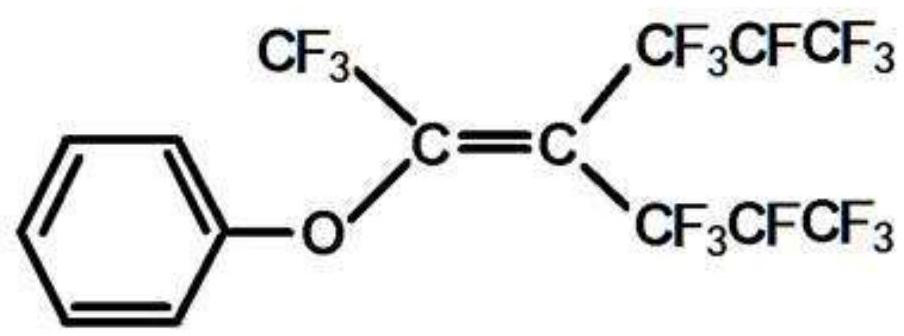

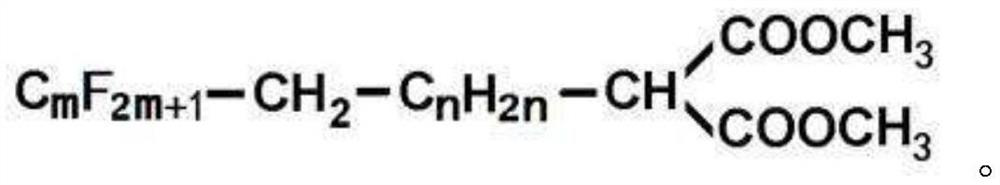

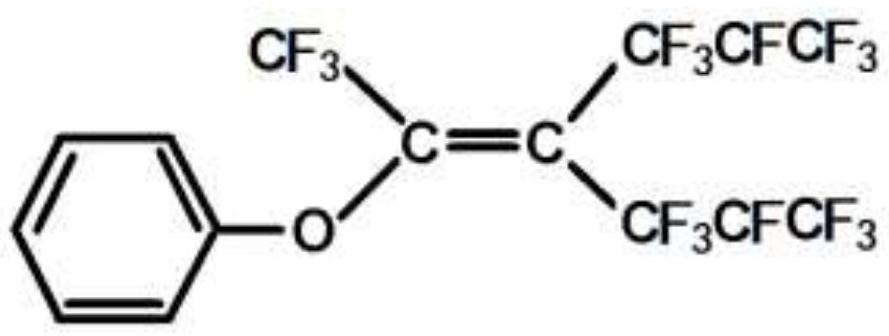

[0045] (2) Mix the liquid raw materials of polymethyl methacrylate, the liquid raw materials of fluororesin A, and the liquid raw materials of fluororesin B according to the required ratio to make a liquid coating, and apply it on the separator by a coating machine. Outside the pattern layer, dry to form the imaging material layer, which must be used for the composite material tape of step (3);

[0046] (3) single-mode pressing the composite strip under the condition of double hard rolls, the imaging material layer is molded by a nickel plate, and another hard roll presses the substrate layer to form a holographic imaging layer;

[0047] (4) Print two-dimensional codes, digital information and graphic ...

Embodiment 2-5、 comparative example 1-7

[0058] Basically according to the steps (1)-(7) of Example 1, prepare the electrochemical aluminum materials of each embodiment and comparative example, the difference is that in step (2), the liquid raw material of polymethyl methacrylate used and the amount of fluorine-containing resin Liquid raw materials, the batching ratio by resin is listed in Table 2 successively, but according to the actual need to add or subtract the feeding amount of each raw material, wherein comparative example 8 adopts the polyvinylidene fluoride water-based coating of relative molecular weight 5000 (800 after evaporation to dryness). ℃ Ash≤0.1m%).

[0059] The compatibility of each emulsion batching in embodiment 2-5, comparative example 1-10 is all very good, is all easy to mix, after mixing, it is all very stable in storage at room temperature within 2 days, and in use; use the 300 mesh The effect of anilox roll coating is better, and the coating speed, drying conditions, and dry coating amount...

Embodiment 6-8

[0066] Basically according to the steps (1)-(7) of Example 5, the anodized aluminum materials of each Example 6-8 were prepared, the difference being the temperature, pressure, and line speed conditions during molding in step (3), as listed in Table 2 below .

[0067] Temperature, pressure, line speed conditions during molding in table 2 step (3)

[0068] temperature °C pressure MPa Linear speedm / min Example 5 180 0.8 45 Example 6 180 1.0 50 Example 7 180 0.6 35 Example 8 160 0.8 20 Example 9 200 0.3 50

[0069] The anodized aluminum materials obtained in Examples 6-8 above have high reflective brightness, clear and crisp holographic details, and clear and sharp digital information and graphic characters, all of which have reached the quality level in these aspects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com