Curing and backfilling construction method for waste mud of deep foundation pit building

A technology for discarded mud and deep foundation pits, applied in chemical instruments and methods, filling, chemical/physical processes, etc., can solve problems such as backfilling is not compact, high backfilling cost, maintenance and removal problems, etc., to achieve fast construction speed, The effect of high strength and controllable quality of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

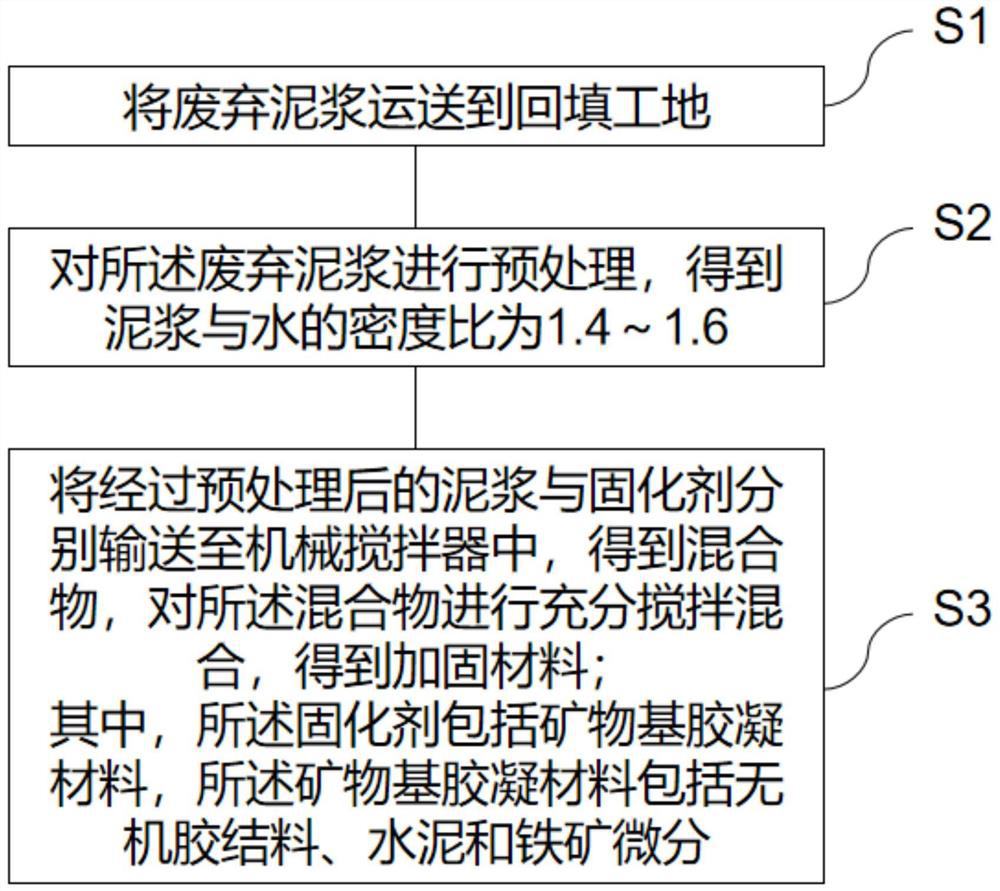

Method used

Image

Examples

Embodiment 1

[0075] Reconstruction and expansion of the original site of a certain obstetrics and gynecology hospital, the project site is located in the core area of the urban center, the surrounding environment is relatively complex, surrounded by existing buildings, and the southwest side is adjacent to the operation section of a subway line (the foundation pit is only 8.9m).

[0076] The original backfilling plan was compaction of lime soil or plain soil. Due to environmental protection requirements, lime soil mixing on site is not allowed, and because the project is located in the center of Heping District, it is difficult to transport soil to the project site and backfill and compact it on site. In order to ensure the construction period and backfill quality, the second basement floor is all backfilled with plain concrete.

[0077] After considering the cost and environmental protection, it is decided to backfill with the construction method of the embodiment of the present applica...

Embodiment 2

[0079] A commercial building project is located in the science and technology business district of a certain city. The foundation pit is surrounded by existing roads and many pipelines. The overall excavation depth of the foundation pit is 10m ~ 11m, and the design of the foundation pit support adopts two anchor rods. Due to the narrow project site, the foundation pit support is close to the red line wall, which cannot meet the requirements of the vehicle dealer, and the foundation pit fertilizer tank is deep , The width is narrow, it is difficult to transport soil to the project site and backfill and tamp the site, the quality of the backfill is difficult to guarantee, and it is easy to leave hidden dangers in the later stage, so the construction method of this application is used for backfilling.

[0080] Due to the high strength of the backfill soil and the large reaction force provided by the passive zone, the brace strips were not replaced when the bolts were removed, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com