Waste molasses-based high-strength environment-friendly formaldehyde-free adhesive as well as preparation method and application thereof

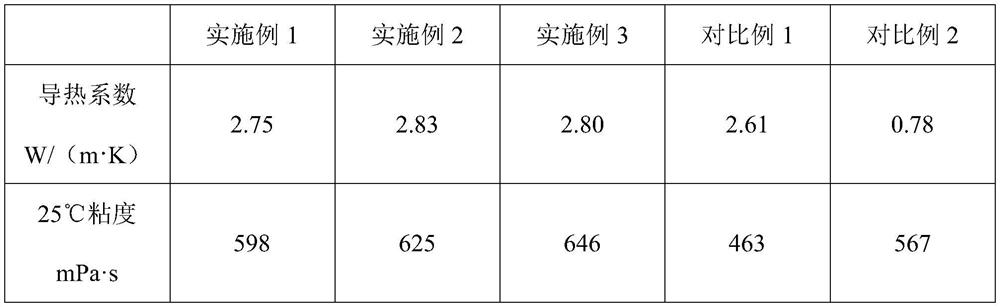

A formaldehyde-free adhesive and waste molasses technology, applied in the preparation of animal glue or gelatin, adhesives, adhesive additives, etc., can solve the problems of low thermal conductivity and poor bonding strength of adhesives, and improve thermal conductivity Poor, improve the bonding strength, improve the effect of heat curing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of waste molasses-based high-strength environmental-friendly formaldehyde-free adhesive, comprising the steps of:

[0029] Mix 100g of waste molasses, 0.5g of phosphoric acid and 40g of water evenly, stir and react at 70°C and 160r / min for 1h, then add 40g of wheat gluten, 4g of carbon nanotubes and 10g of graphene fibers to it, at 60°C, Stir and react at 160r / min for 1h, then add 5g of silica microspheres and 6gKH560 silane coupling agent to it, stir and react at 30°C for 1h at 160r / min, then add 3g of sodium sulfite to it, at 80°C, Stir and react at 400r / min for 1h, then cool to room temperature, add 2g of polyacrylamide thereto, and stir at 160r / min for 1h to obtain an adhesive.

Embodiment 2

[0031] A preparation method of waste molasses-based high-strength environmental-friendly formaldehyde-free adhesive, comprising the steps of:

[0032] Mix 80g of waste molasses, 1g of phosphoric acid and 45g of water evenly, stir and react at 70°C and 160r / min for 1h, then add 50g of wheat gluten, 4g of carbon nanotubes and 10g of graphene fibers to it, and stir at 60°C and 160r / min Stir the reaction at a speed of 1 / min for 1 h, then add 8 g of silica microspheres and 8 g of KH560 silane coupling agent to it, stir and react for 1 h at 30°C and 160r / min, then add 4g of sodium sulfite to it, at 80°C, 400r The mixture was stirred and reacted at a speed of 160r / min for 1h, then cooled to room temperature, 3g of polyacrylamide was added thereto, and stirred at a speed of 160r / min for 1h to obtain an adhesive.

Embodiment 3

[0034] A preparation method of waste molasses-based high-strength environmental-friendly formaldehyde-free adhesive, comprising the steps of:

[0035] Mix 100g of waste molasses, 2g of phosphoric acid and 50g of water evenly, stir and react at 70°C and 160r / min for 1h, then add 60g of wheat gluten, 5g of carbon nanotubes and 12g of graphene fibers to it, and stir at 60°C and 160r / min Stir the reaction at a speed of 1 / min for 1 h, then add 5 g of silica microspheres and 8 g of KH560 silane coupling agent to it, stir and react for 1 h at 30 °C and a speed of 160 r / min, then add 4 g of sodium sulfite to it, at 80 °C, 400 r The mixture was stirred and reacted at a speed of 160r / min for 1h, then cooled to room temperature, 2g of polyacrylamide was added thereto, and stirred at a speed of 160r / min for 1h to obtain an adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com