Corrugated board column-to-column die cutting machine

A technology of corrugated cardboard and round pressing, which is applied in the field of corrugated cardboard round pressing and round die-cutting machines, can solve the problems of waste and leftover material penetration, high labor intensity of personnel, and difficult processing work, so as to avoid the safety of personnel and the environment, and reduce the Labor intensity, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

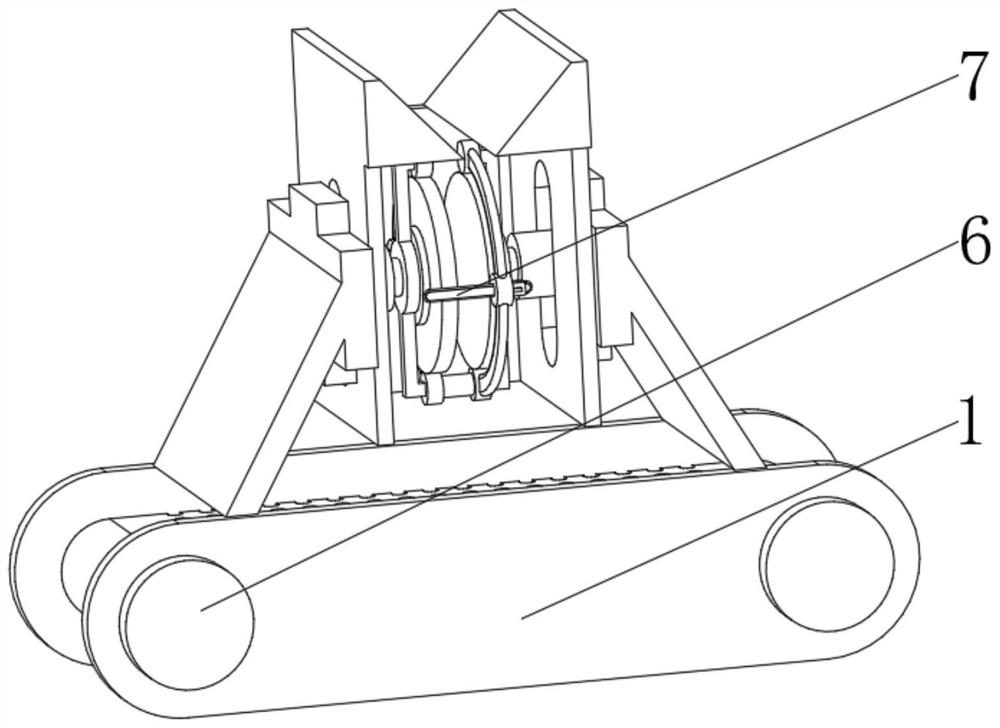

[0039] see Figure 1-3 , the present invention provides a technical solution: a corrugated cardboard rotary die-cutting machine, specifically comprising:

[0040] Support frame 1, the support frame 1 has a round end plate body, and a protective bottom plate 2 installed in the middle of the bottom of the inner cavity of the round end plate, and a T-shaped dust suction fan 3 installed on the top of the protective bottom plate 2, and a T-shaped dust suction fan 3 installed on the round end The rotating shaft 4 on both sides of the inner cavity of the plate, the feeding belt 5 installed on the outer surface of the rotating shaft 4, and the drive motor 6 installed on the outside of the round end plate body and at the position of the rotating shaft 4, and installed on the top of the round end plate body The circular die-cutting device 7 can absorb the airflow through the design of the T-shaped dust suction fan 3, and the strong negative air pressure can collect the powder generated ...

Embodiment 2

[0047] see Figure 1-4 On the basis of Embodiment 1, the present invention provides a technical solution: the die-cutting device 77 includes:

[0048] Rotating motor 771, this rotating motor 771 has cylindrical main body, and is installed in cylindrical main body away from the rotating connecting plate 772 of electric telescoping rod 76 side, and is installed in rotating connecting plate 772 and is away from the circular pressing plate 773 of cylindrical main body side, and is installed in The auxiliary rod 774 on both sides of the outer surface of the cylindrical main body, and the fitting guide wheel 775 that is installed on the auxiliary rod 774 away from the end of the cylindrical main body, and the semicircle mounting rod 776 that is installed on the outer surface of the fitting guide wheel 775, and is installed on the semicircle mounting rod The cutting device 777 in the middle position of 776 is installed on the pressure switch 778 that is located at the front of the ci...

Embodiment 3

[0053] see Figure 1-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the cutting device 777 includes:

[0054] Positioning column 7771, the positioning column 7771 has a cylinder, and an L-shaped fixed frame 7772 installed on the top of the cylinder, and a lifting driver 7773 installed on the top of the L-shaped fixed frame 7772, and a rod-shaped rod installed in the middle of the lifting driver 7773 Cutter 7774. Through the design of the lifting driver 7773, the processing distance of the rod cutter 7774 can be adjusted, which is suitable for die-cutting of corrugated cardboard with different thicknesses. At the same time, the distance adjustment of the rod cutter 7774 assists the blade of the rod cutter 7774 to loosen , to avoid the occurrence of cutting jamming.

[0055] One end of the rod-shaped cutter 7774 away from the lifting driver 7773 runs through the positioning column 7771 and extends to the side of the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com