Brittleness-keeping method for physically treating black fungus and black fungus sauce processing technology

A processing technology, technology of black fungus, applied in food heat treatment, food science, fat-containing food ingredients, etc., can solve the problems of not meeting the processing needs of black fungus sauce, lack of black fungus cans, and restricting market demand, etc., to achieve low cost, Crisp taste and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Modification of black fungus: select dry black fungus without insects and moisture content <14%, remove the impurities, put the black fungus in a retort bag (unsealed), each with a sample volume of 250g, and use high-pressure steam Sterilize the pot at 110°C for 30 minutes, and take it out for later use.

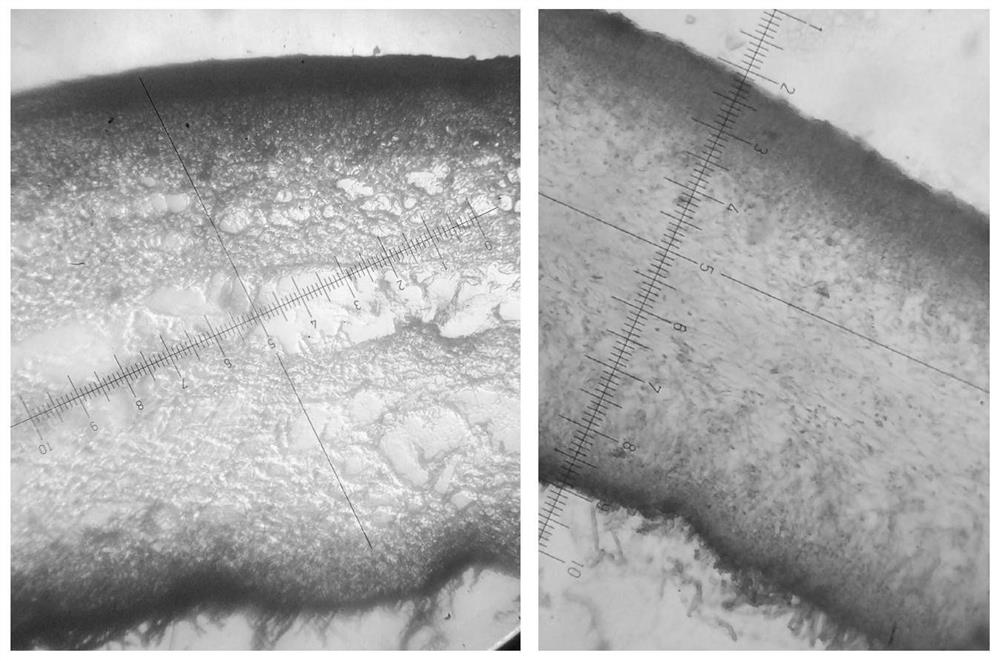

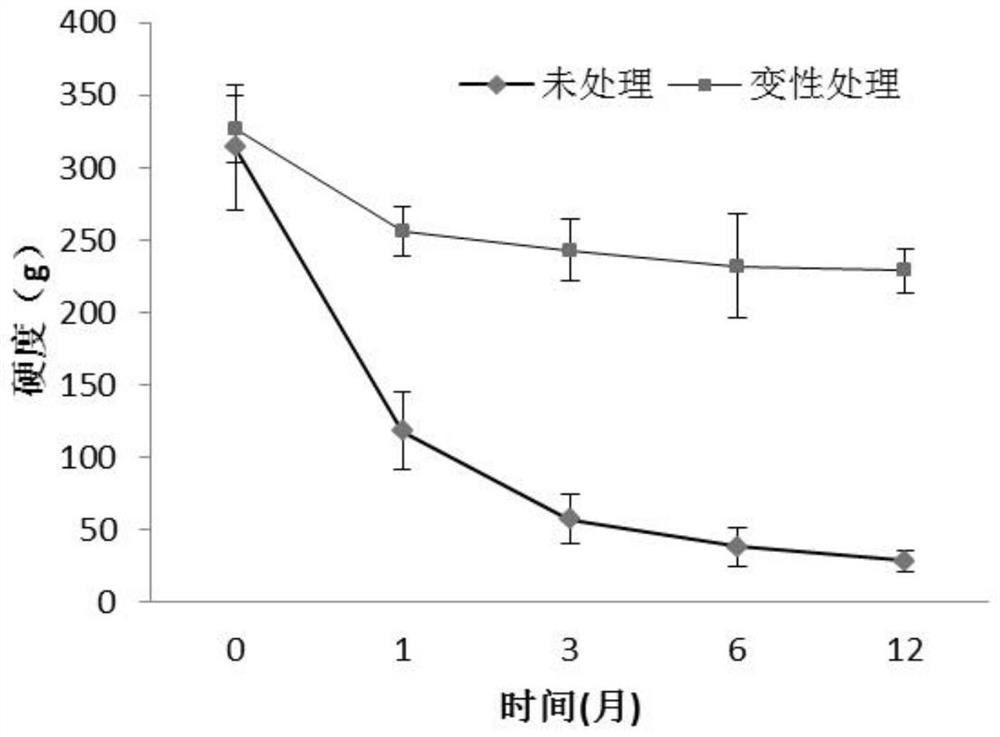

[0034] 2) Rehydration: rehydrate the black fungus obtained in step 1), and the rehydration time is 6 hours. figure 1 It shows that the untreated black fungus has been soft and rotten after storage for 30 days after rehydration, but there is no obvious change after the method of this embodiment is used. figure 2 The microstructure shows that the soft and rotten black fungus has separated from the upper and lower layers, and there is no obvious change through the black fungus modified by the method of the present embodiment. image 3 It is shown that as the storage time prolongs, the hardness of the untreated black fungus decreases rapidly, while the hardness of th...

Embodiment 2

[0036] 1) Modification of black fungus: select dry black fungus without insects and moisture content <14%, remove the impurities, put the black fungus in a retort bag (unsealed), each sample is 300g, and use high-pressure steam Sterilize the pot at 115°C for 30 minutes, and take it out for later use.

[0037] 2) Rehydration: rehydrate the black fungus obtained in step 1), and the rehydration time is 4 hours.

[0038] 3) Frying: Drain the surface moisture of the rehydrated black fungus, and then fry them in edible oil for 8 minutes at a temperature of 130°C, take them out and set aside.

[0039] 4) Stir-fried sauce: Prepare 250g of salad oil, heat the oil in a pan, then add 50g of garlic, 10g of crushed peanuts, 10g of sesame seeds, sauté until fragrant, then add 120g of soybean paste, 120g of Pixian bean paste and 70g of sweet noodle sauce, and fry After the aroma, add 100g of crispy bamboo shoots, 50g of Chaotian pepper, 350g of fried black fungus obtained in step 3, fry for...

Embodiment 3

[0042] 1) Modification of black fungus: select dry black fungus without insects and moisture content <14%, remove the impurities, put the black fungus in a retort bag (unsealed), with a sample size of 500g per portion, and use high pressure steam Sterilize the pot at 121°C for 30 minutes, and take it out for later use.

[0043] 2) Rehydration: rehydrate the black fungus obtained in step 1), and the rehydration time is 5 hours.

[0044] 3) Frying: Drain the surface moisture of the rehydrated black fungus, fry them in cooking oil for 10 minutes, take them out and set aside.

[0045] 4) Stir-fried sauce: Prepare 250g of salad oil, heat the oil in a pan, then add 50g of garlic, 10g of crushed peanuts, 10g of sesame seeds, sauté until fragrant, then add 120g of soybean paste, 120g of Pixian bean paste and 70g of sweet noodle sauce, and fry After the aroma, add 100g of crispy bamboo shoots, 50g of Chaotian pepper, 350g of fried black fungus obtained in step 3, fry for 5 minutes, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com