Taro flavor Maillard reactant as well as preparation method and application thereof

A Maillard reactant and flavor technology, applied in the food field, can solve the problems of unnatural flavor, poor temperature resistance, complicated preparation process, etc., and achieve the effects of mellow and natural aroma, mild reaction conditions, and simple preparation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

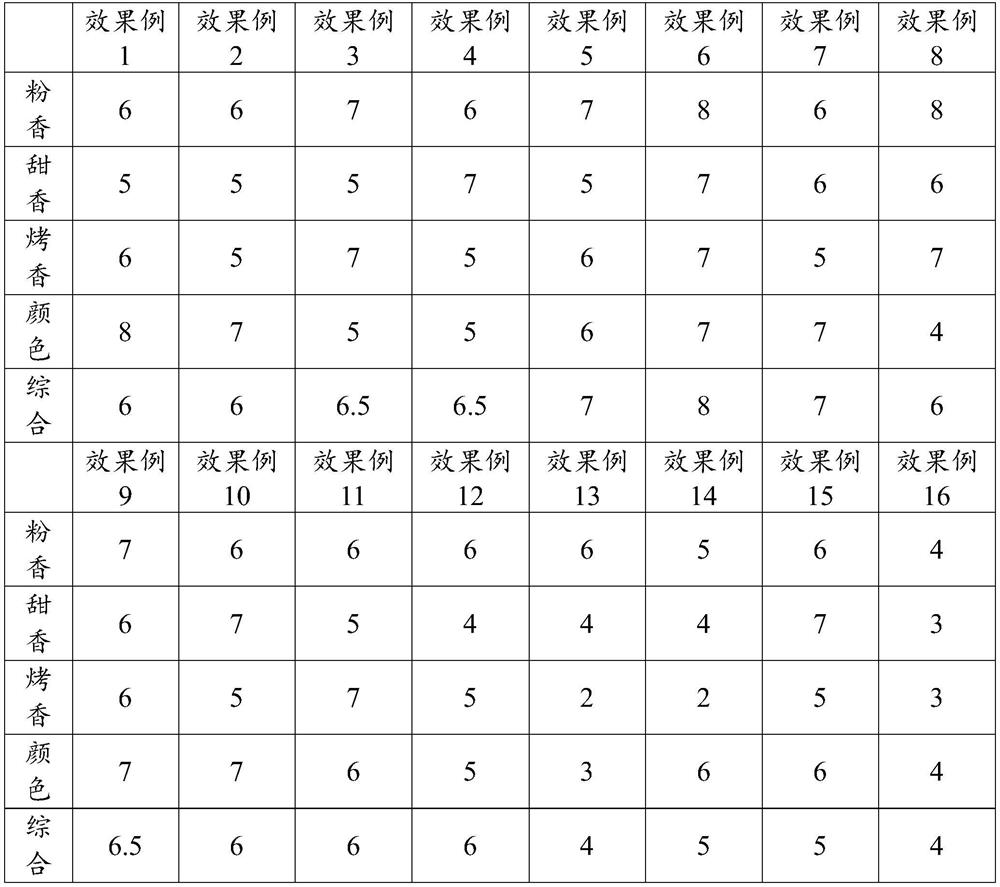

Examples

Embodiment 1

[0025] A taro-flavored Maillard reactant as an embodiment of the present invention comprises the following components by mass percentage: 8% glucose monohydrate, 15% F55 fructose syrup, 4.6% proline, threonine 1.2%, alanine 1.8%, aspartic acid 1.4%, glycerin 18%, white sugar 30%, water 20%. The preparation method of the taro-flavored Maillard reactant of the present embodiment comprises the following steps: (1) weighing: weigh the above-mentioned substances by mass percentage, and put them into the reaction bottle in the order of adding the liquid first and then adding the solid; (2) ) to adjust PH: use sodium hydroxide or hydrochloric acid to adjust the pH value of the system to about 7.5-8; (3) thermal reaction: adjust the temperature of the heating mantle, and react at 100 ° C for 2 hours; (4) cooling: after the reaction is completed, turn off the heating mantle and Stirrer, let cool naturally.

Embodiment 2

[0027] A taro-flavored Maillard reactant as an embodiment of the present invention comprises the following components by mass percentage: 8% fructose, 15% F55 fructose syrup, 4.6% proline, and 1.2% threonine , aspartic acid 2.8%, glycerin 18.4%, white sugar 30%, water 20%. The preparation method of the taro-flavored Maillard reactant of the present embodiment comprises the following steps: (1) weighing: weigh the above-mentioned substances by mass percentage, and put them into the reaction bottle in the order of adding the liquid first and then adding the solid; (2) ) to adjust PH: use sodium hydroxide or hydrochloric acid to adjust the pH value of the system to about 7-7.5; (3) thermal reaction: adjust the temperature of the heating mantle, and react at 102°C for 2 hours; (4) cooling: after the reaction is completed, turn off the heating mantle and Stirrer, let cool naturally.

Embodiment 3

[0029] A taro-flavored Maillard reactant as an embodiment of the present invention comprises the following components in terms of mass percent: glucose monohydrate 10%, F55 fructose syrup 28%, proline 4.6%, threonine 0.35%, lysine 0.6%, methionine 0.05%, cysteine 0.5%, glycerol 18.4%, white sugar 17.5%, water 20%. The preparation method of the taro-flavored Maillard reactant of the present embodiment comprises the following steps: (1) weighing: weigh the above-mentioned substances by mass percentage, and put them into the reaction bottle in the order of adding the liquid first and then adding the solid; (2) ) to adjust PH: use sodium hydroxide or hydrochloric acid to adjust the pH value of the system to about 7-7.5; (3) thermal reaction: adjust the temperature of the heating mantle, and react at 102°C for 2 hours; (4) cooling: after the reaction is completed, turn off the heating mantle and Stirrer, let cool naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com