Laser, optical equipment and production method

A laser and laser technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of pump light surplus, beam quality degradation, device matching difficulties, etc., achieve high market application value, suppress parasitic oscillation, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

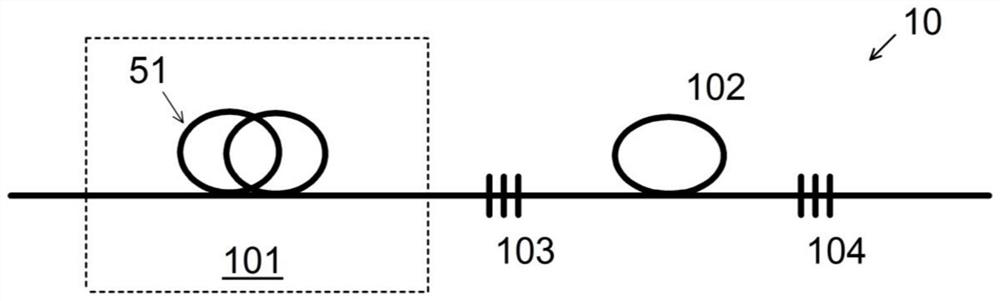

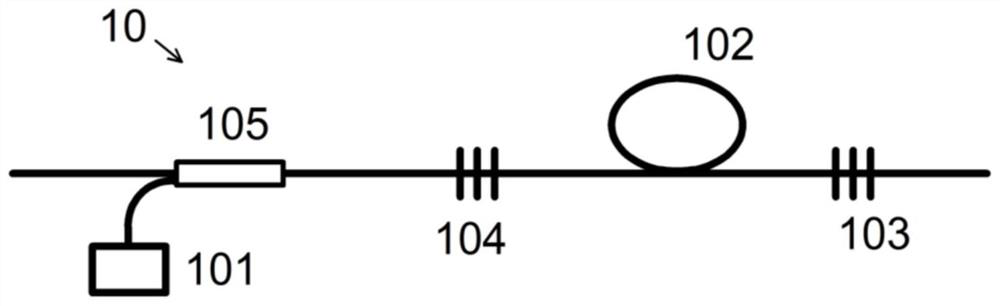

[0049] Lasers that generate laser light near 980nm in the prior art have the problems of low laser efficiency, difficulty in making optical fibers, and inability to output single-mode laser light.

[0050] In order to solve the above technical problems, the prior art proposes a technical approach for pumping ytterbium-doped fibers based on the core of a neodymium-doped fiber laser. The gain of the first signal laser is achieved through an ytterbium-doped fiber amplifier, and the ytterbium-doped fiber is transformed into a glass rod with a tapered structure to increase laser efficiency.

[0051] However, after the applicant's research, the optical fiber amplifier solution needs to consider the problem of return light isolation in the application of the aforementioned high-power single-frequency narrow-linewidth, ultrafast fiber laser, and needs to introduce optical fiber devices such as isolators, which make the 980nm laser The output power of the laser is limited, resulting in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com