Reactor based on full-ceramic dispersion micro-packaging fuel and silicon carbide cladding

A micro-encapsulation and reactor technology, applied in the field of reactors, can solve the problems that the safety mechanism has not broken through the pressurized water reactor, and has not fundamentally realized inherent safety, etc., to achieve the effect of eliminating release risks, eliminating serious accidents, and strong tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

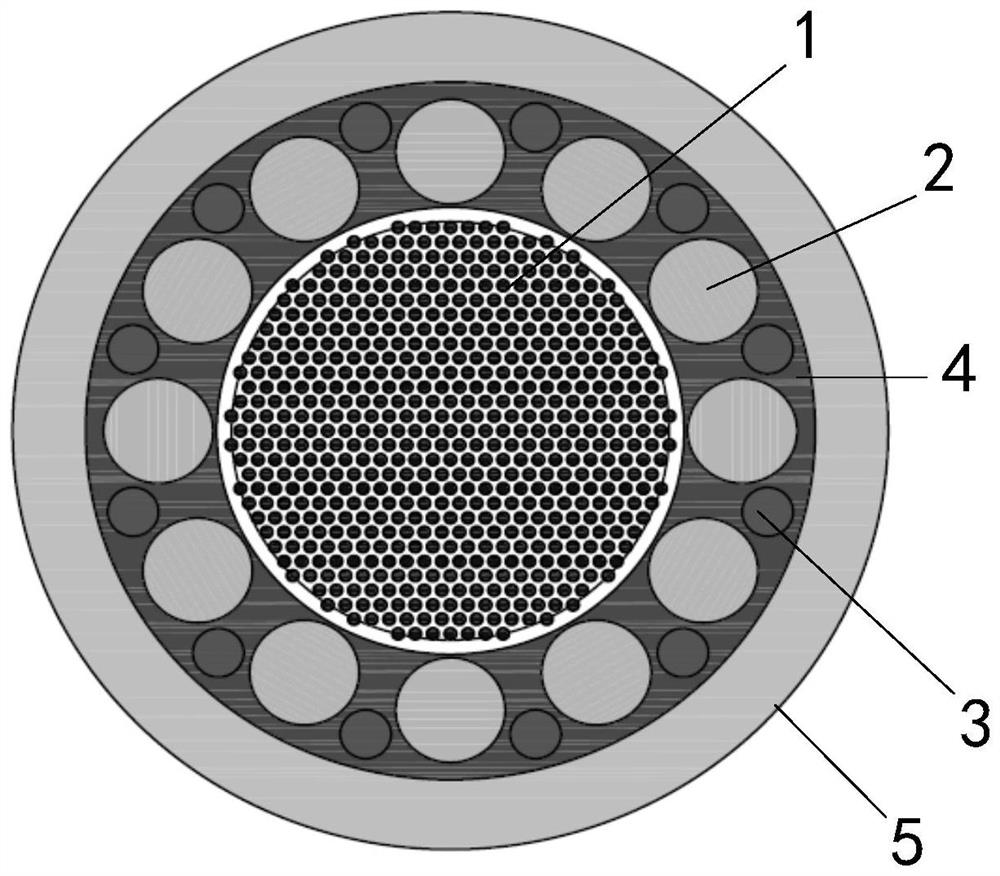

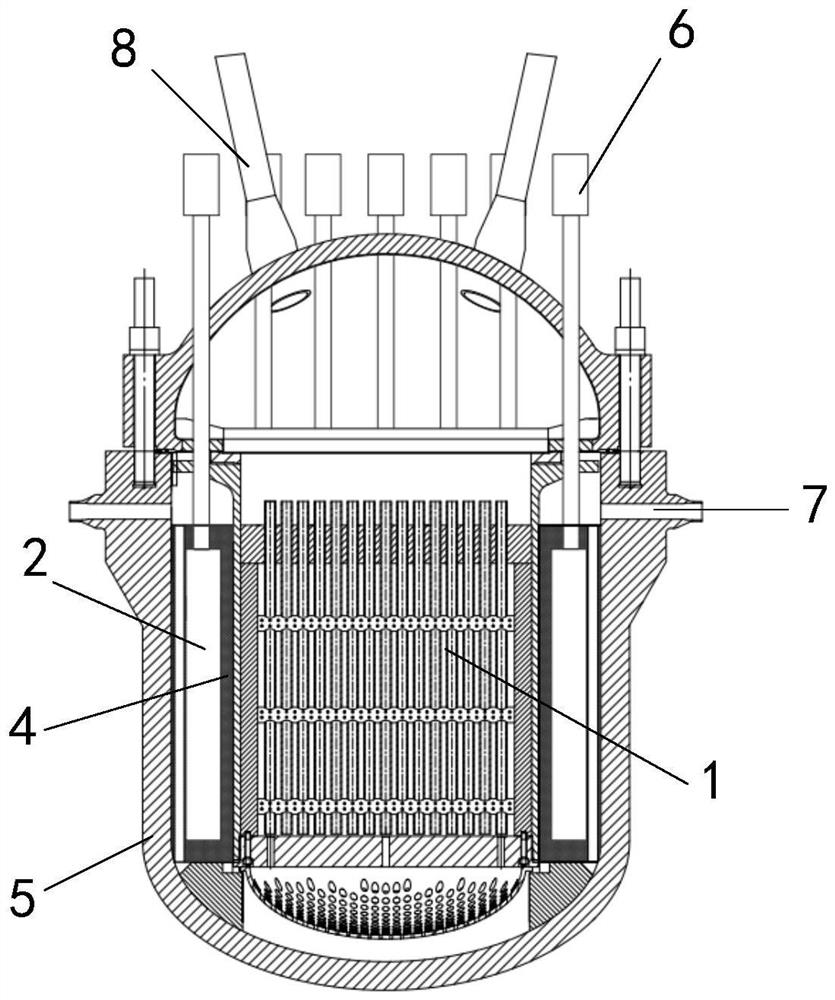

[0034] In order to eliminate the risk of large-scale radioactive release caused by core melting and achieve inherent safety, an embodiment of the present invention provides a reactor based on all-ceramic dispersed micro-encapsulated fuel and silicon carbide cladding. figure 1 and 2 As shown, it includes: a pressure vessel 5; the core active area is located in the pressure vessel; the core is located in the core active area and is provided with several all-ceramic dispersion micro-encapsulated fuel element rods 1; the reflection area is located at the pressure Outside the core active area in the container; the all-metal reflective layer 4 is filled in the reflective area and is used to reflect leaked core neutrons; and the rotating drum 2 is arranged on the all-metal reflective layer. The rotary drum is connected with a rotary drum drive mechanism 6 .

[0035] Therefore, the embodiment of the present invention uses all-ceramic dispersed micro-encapsulated fuel element rods to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com