Device and method for quantitative determination of residual silicon hydrogen in organosilicon sample

A quantitative determination, silicone technology, applied in the field of chemical analysis and detection, to achieve the effect of reducing the detection limit, avoiding oxidation, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0088] Prepare the isoamyl alcohol solution of sodium isoamyloxide as the reaction solution:

[0089] 5.0 g of sodium hydroxide and 100 mL of isoamyl alcohol were mixed, then shaken and dissolved at 40° C. for 15 h of reaction, and then the temperature was raised to reflux to remove the water generated by the reaction to obtain a reaction solution.

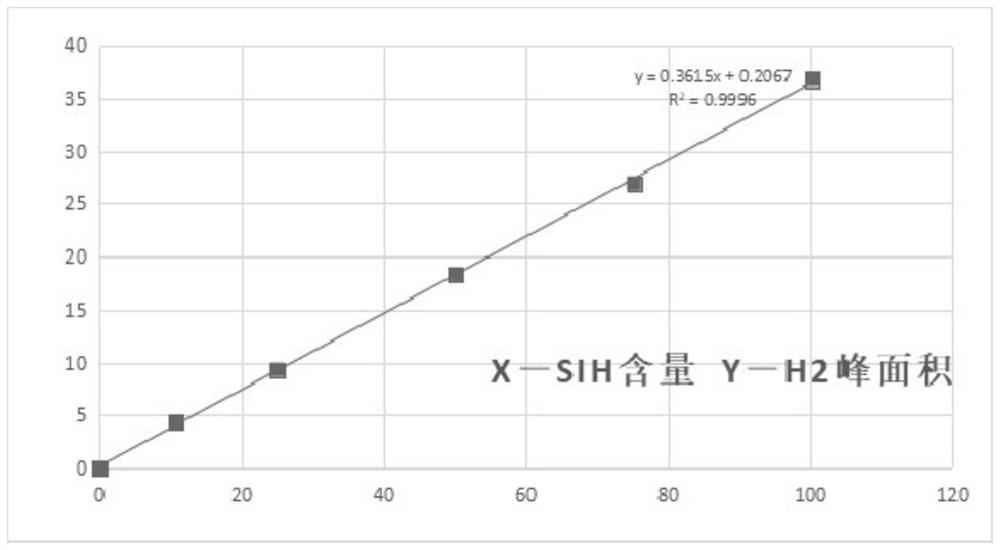

[0090] Standard curve drawing example 1:

[0091] Constructing a standard curve for the quantitative determination of residual silicon hydrogen in organosilicon comprises the following steps:

[0092] (a) Prepare standard solution:

[0093]The hydrogen-containing silicone oil with a known silicon hydrogen content of 46.69% (in terms of Si-H) is used as a silicon hydrogen standard substance, and octamethylcyclotetrasiloxane is used as a solvent to perform two dilutions to prepare a trace amount of silicon hydrogen concentration (in terms of Si-H). -H meter) is 10.7mg / kg, 25.0mg / kg, 50.0mg / kg, 75.2mg / kg, 100.4mg / kg series standard...

Embodiment 1~3

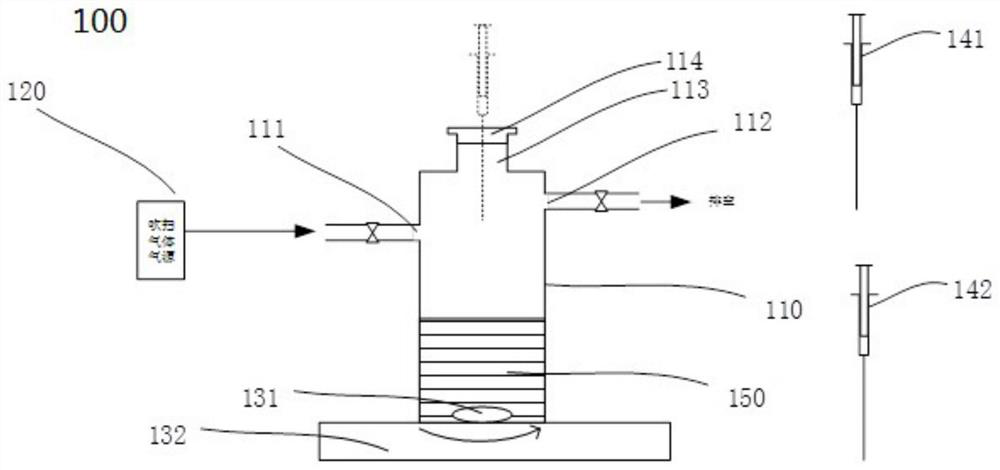

[0130] A method for quantitatively determining residual silicon hydrogen in an organosilicon sample, using the "pretreatment device 100 for quantitatively determining residual silicon hydrogen in an organosilicon sample" provided in the specific embodiment, comprising the following steps:

[0131] (1) Add the reaction solution (the reaction solution prepared in Preparation Example 1) to the silicon hydrogen reaction bottle, and block the sample inlet of the silicon hydrogen reaction bottle with a sealing rubber gasket; turn on the magnetic stirring until the speed is 350 rpm minute;

[0132] (2) Connect the gas purging device (nitrogen gas source), replace the gas of the silicon hydrogen reaction bottle with nitrogen, and close the air inlet and the gas outlet of the silicon hydrogen reaction bottle;

[0133] (3) Inject the sample to be tested into the silicon hydrogen reaction vial with a sample injection device, and react for 10 minutes; the amount of the sample to be tested...

Embodiment 4

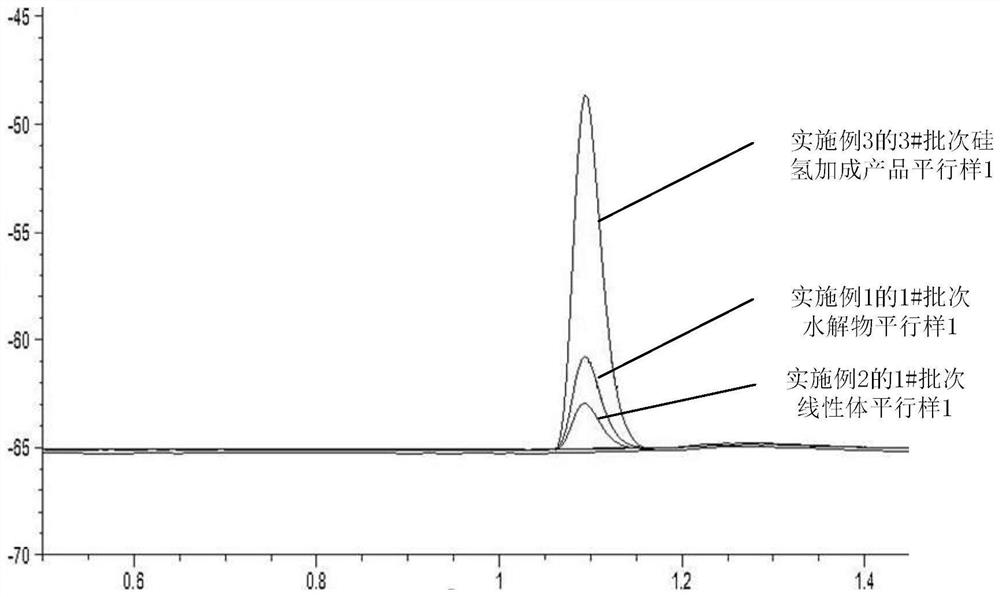

[0138] The organosilicon sample in Example 4 is a ring product (4 batches of samples), and two parallel samples were measured simultaneously, and the measurement results are shown in Table 4.

[0139] Table 4 shows the measurement results of silicon hydrogen in Examples 1-3, and the unit of the measurement results is mg / kg.

[0140] Table 4

[0141]

[0142]

[0143] Among them, the batches of hydrolyzate samples 1#, 2#, 3#, and 4# came from the finished tank of dimethyldichlorosilane hydrolyzate in the No. 2 Branch Factory of Jiangxi Lanxinghuo Silicone Co., Ltd.; Batches 3# and 4# come from the linear body finished tanks of the No. 1 Branch Factory of Jiangxi Lanxinghuo Silicone Co., Ltd.; batches of 1#, 2#, 3# and 4# of the samples of hydrosilicon addition come from Jiangxi Lanxinghuo Organic Silicon Co., Ltd. Silicon Co., Ltd. storage branch end epoxy product library; ring body samples 1#, 2#, 3#, 4# batches are from the ring body product library of Jiangxi Blue Xin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com