Pretreatment method and pretreatment system for detecting radium content in liquid

A pretreatment and liquid technology, applied in the direction of measuring devices, radiation measurement, test sample preparation, etc., can solve the problems of non-continuous, time-consuming and labor cost, personal injury of experimenters, etc., to avoid cross-contamination, reduce Labor cost, the effect of improving the accuracy of dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

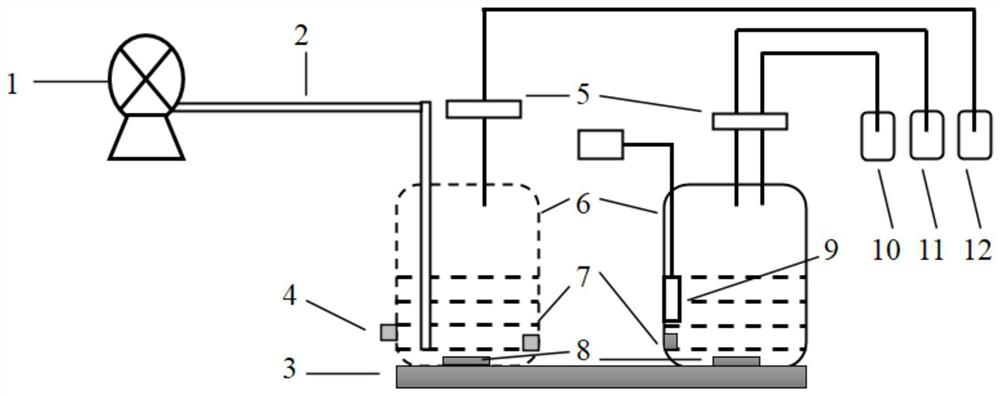

[0031] Such as figure 1 As shown, the present invention provides a kind of radium content detection pretreatment system in the liquid, comprises suction filter tube 2, magnetic heating rotary table 3, syringe pump 5, reaction device 6 and medicine storage tank (barium chloride solution storage tank 10, Sulfuric acid solution storage tank 11 and EDTA-2Na solution 12 storage tanks).

[0032] The suction filter tube 2 is located on the first side of the magnetic heating turntable 3, and the drug storage tank is located on the second side of the magnetic heating turntable 3, and the first side is opposite to the second side.

[0033] The suction filter pipe 2 is connected with the suction filter pump 1, and is used for siphoning to remove the supernatant. The reaction device 6 is located on the magnetic heating turntable 3 , and an infrared liquid level measuring instrument 4 is arranged on the side wall of the reaction device 6 to reflect the liquid level change in the reaction ...

Embodiment 2

[0037] The present invention provides a pretreatment method for detecting radium content in liquid. The radium content detection pretreatment system in liquid described in Embodiment 1 of the present invention is adopted. The pretreatment method for detecting radium content in liquid includes the following steps: S1: reacting The device 6 is placed on the side of the magnetic heating rotary table 3 close to the sample storage tank, which is recorded as the second side of the magnetic heating rotary table 3, and 1-5 liters of liquid samples are placed in the reaction device 6, and the hardness tester 9 measures the liquid samples The hardness and feedback the measurement result X to the central control unit.

[0038] S2: The central control unit calculates the amount V of EDTA-2Na to be added according to the prestored formula and the hardness measurement result X fed back by the hardness meter 9 .

[0039] S3: Turn on the heating button of the magnetic heating turntable 3 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com