New material-based butyl rubber pipe performance detection equipment

A technology of butyl rubber and testing equipment, which is applied in the direction of measuring devices, instruments, etc., and can solve the problems of not being able to adapt to rubber tubes of different lengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

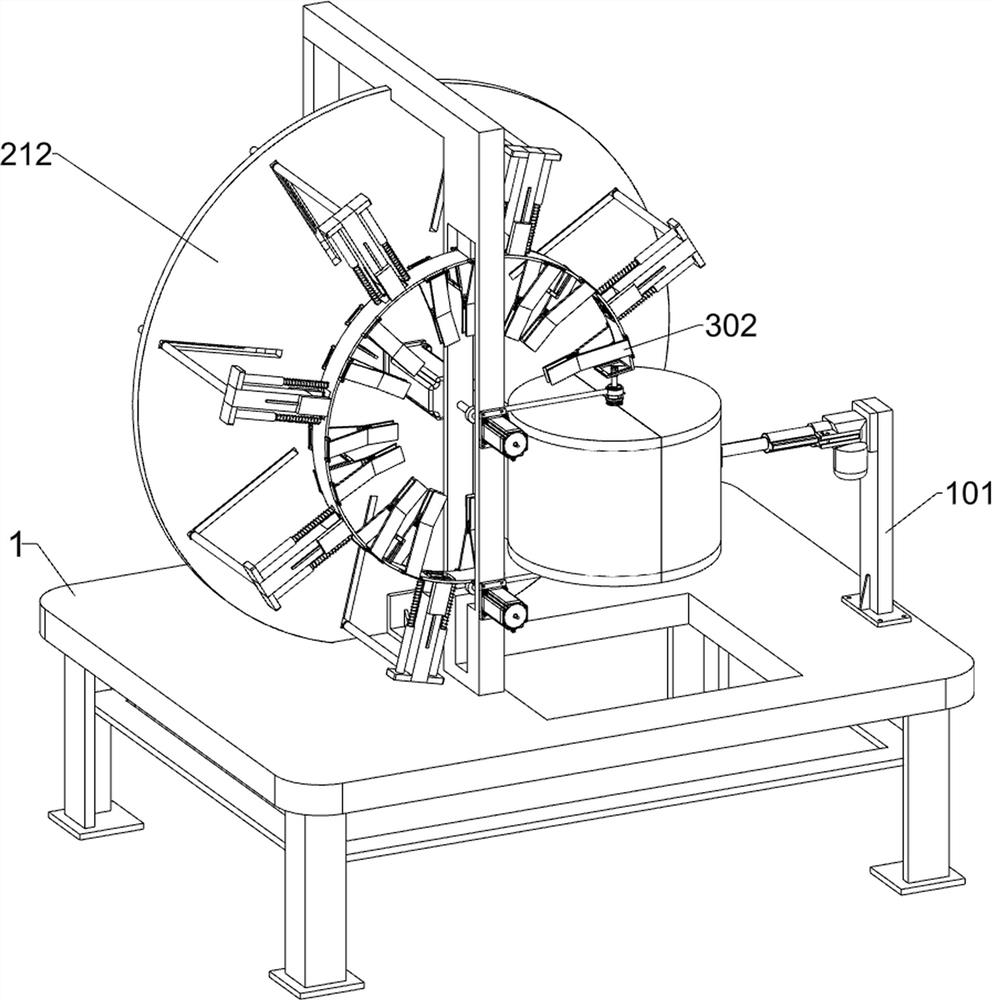

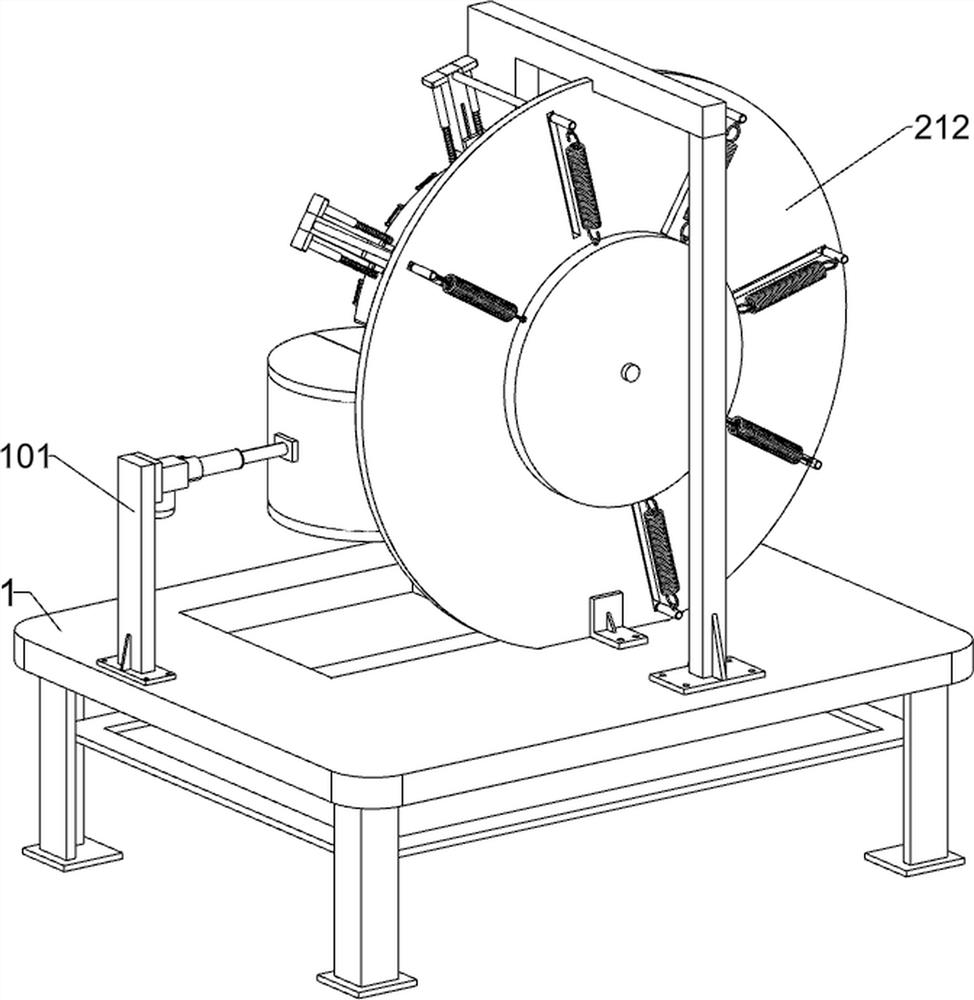

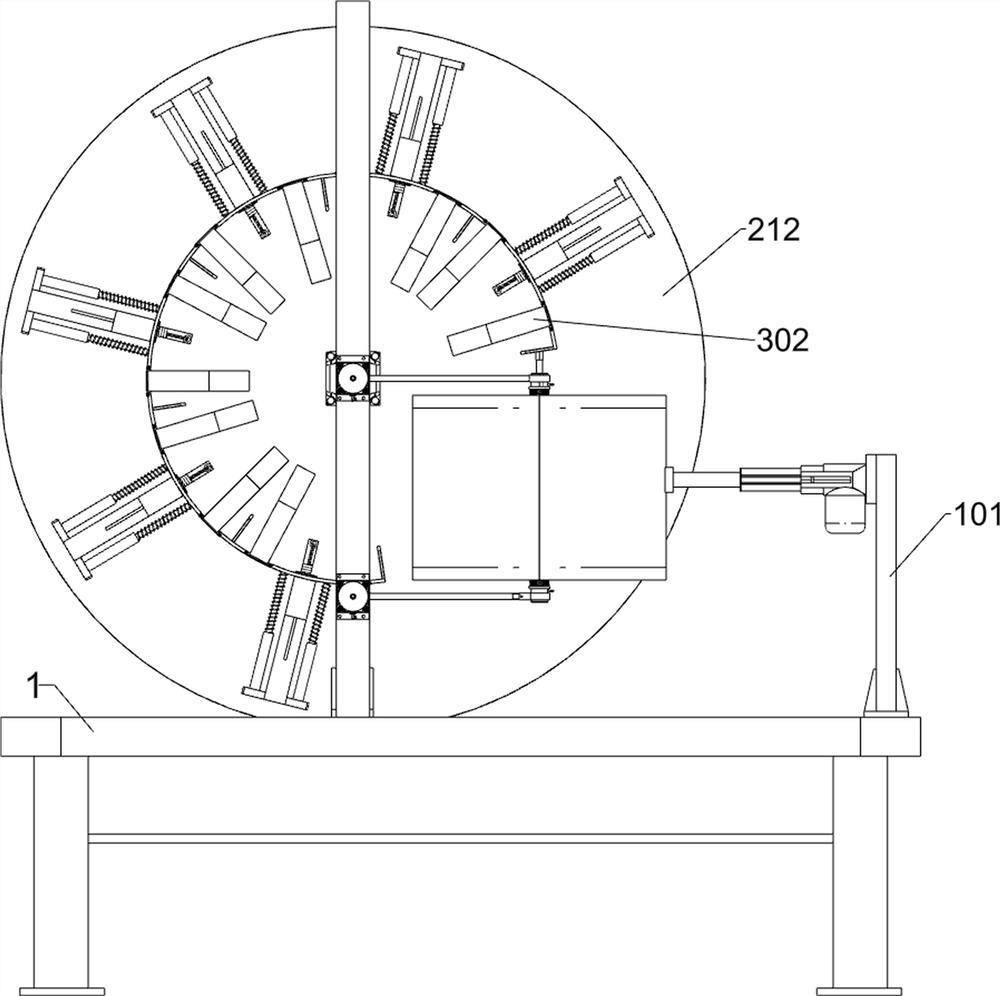

[0036] A performance testing equipment for butyl rubber tubes based on new materials, such as Figure 1-13 As shown, it includes a base frame 1, an air tightness detection component and a bending resistance detection component; The right part is equipped with an air tightness detection component for testing the air tightness of the butyl rubber tube; the air tightness detection component is connected with the bending resistance detection component.

[0037] The air tightness detection assembly includes a fixed plate 101, an electric push rod 102, a sealing cylinder 103, a first arc-shaped plate 104, a second arc-shaped plate 105, an electric slider 106, an ozone detector 107, a U-shaped frame 108, a small Motor 109, hook plate 110, gantry 111, auxiliary motor 112, transmission rod 113, connecting rod 114, fixed cylinder 115, air duct 116, fixed ring 117, buffer spring 118, cylindrical air bag 119, tapered rubber plug 120 and air nozzle 121; the front right part of the bottom ...

Embodiment 2

[0047] On the basis of Example 1, such as figure 1 with Figure 14-15As shown, it also includes a wear resistance detection assembly. There are a plurality of wear resistance detection assemblies in a ring array on the ring mounting plate 201, and the wear resistance detection assembly on the right includes a second hinged frame 301 and a friction plate 302; the ring installation A second articulated frame 301 is fixedly connected to the right front part and the right rear part of the plate 201; two second articulated frames 301 are respectively hinged with a friction plate 302 through a torsion spring on the back side; the middle parts of the two friction plates 302 face each other. Each side is provided with a friction part 30301.

[0048] Since the butyl rubber tube is often dragged on the ground during actual use, especially when dragged on the concrete floor, the butyl rubber tube is easily worn by repeated friction on the ground, and it is necessary to test the wear res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com