Lubricating device for hydraulic cylinder and hydraulic cylinder with lubricating device

A technology of lubricating device and hydraulic cylinder, which is used in fluid pressure actuating devices, engine lubrication, engine components, etc., can solve the problems of large running resistance and easy wear of seals, and achieve the effect of reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

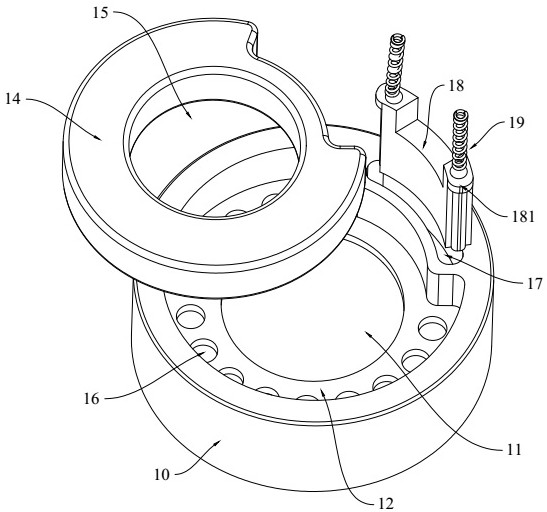

[0033] Please refer to Figure 1 to Figure 8 , The preferred embodiment of the present invention provides a lubricating device for a hydraulic cylinder, which is mainly used in the hydraulic cylinder to reduce the running resistance of the piston and reduce the wear of the seal. The lubricating device for the hydraulic cylinder mainly includes a cylinder body 10, which is a cylindrical structure with a hollow interior and open ends at both ends. The cylinder body 10 is made of steel or aluminum alloy to have a certain strength and maintain The structure is stable and does not deform under pressure. The cylinder body 10 is installed in the cylinder body of the hydraulic cylinder when in use, specifically, it is installed on the top of the cylinder body of the hydraulic cylinder. Body 10 is fixed in the cylinder body of hydraulic cylinder and keeps cylindrical body 10 motionless. The middle part of the inner wall of the cylinder body 10 is fixed with a partition ring 12 to sep...

Embodiment 2

[0041] This preferred embodiment provides a hydraulic cylinder, please refer to Figure 9 , mainly includes a cylinder 21, a piston 22 and a piston rod 23, the piston 22 is slidingly arranged in the cylinder 21, one end of the piston rod 23 is fixedly connected to the piston 22, and the other end extends out of the cylinder cover 25 at the top of the cylinder 1, and the cylinder 21 The bottom of the cylinder is provided with a water inlet 27, the top is provided with a cylinder cover 25, the cylinder cover 25 is provided with a vent hole 26, the cylinder body 21 is provided with the hydraulic cylinder lubricating device of embodiment 1, and the cylinder of the hydraulic cylinder lubricating device The body 10 is installed on the top of the cylinder body 21, the piston 22 is located below the cylinder body 10, the piston rod 23 passes through the center hole 15 of the separator ring 12 and the oiling part 14, and the communication hole 17 is connected to the cylinder head 25 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com