Intelligent hogging moment tensioning device for bottom die

A technology of tensioning device and negative bending moment, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve problems such as prone to tilting or collapse, and achieve improved handling adaptability, increased stability, and improved operational stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

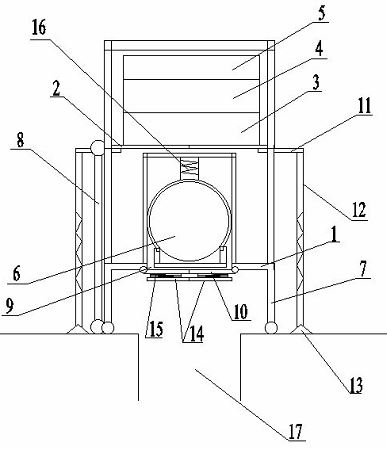

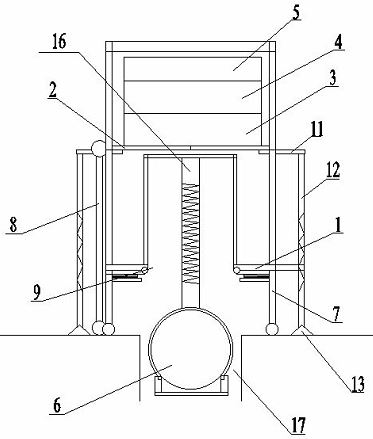

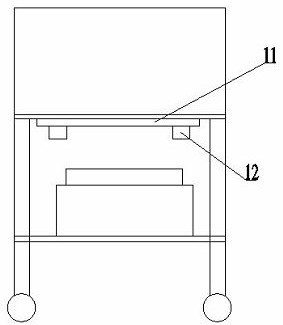

[0031] Please also refer to the description attached Figure 1-Figure 3 , the present invention provides an intelligent negative bending moment tensioning device for the bottom mold, which solves the problem that the structure of the bridge based on the bottom mold in the prior art is prone to inclination or collapse and other safety hazards during the tensioning process. It is already in the stage of actual experimental use.

[0032] The device includes a base 1, an expandable mounting frame 2 is arranged on the base 1, a power supply 3 and a motor 4 are arranged on the mounting frame 2, and the power supply 3 and the motor 4 are electrically connected with the central controller 5, A tensioning jack 6 that can be lifted and lowered is arranged between the mounting frame 2 and the base 1, a movable foot 7 and a retractable fixed foot 8 are arranged below the base 1, and a working port 9 is provided on the base 1, The working port 9 is provided with an automatic working door ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com