Method for co-production of acid and nitrogen-rich carbon-based oxygen reduction catalyst from lignocellulose biomass

A lignocellulosic and biomass technology, applied in the field of lignocellulosic biomass co-production acid and nitrogen-rich carbon-based oxygen reduction catalyst, to achieve the effect of easy control, low cost and developed pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

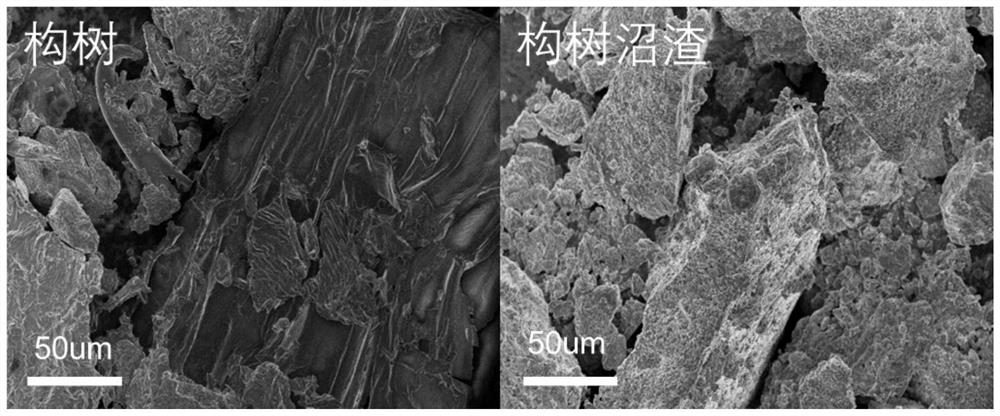

[0035] A method for utilizing mulberry to co-produce acid and high nitrogen-containing porous carbon materials, comprising the steps of:

[0036] S1: Crush the mulberry tree, mix it with water at a solid-to-liquid ratio of 1:20, and perform pretreatment in a hydrothermal reactor at 200°C for 6 hours.

[0037] S2: The material after pretreatment in step S1 is transferred to the acid production reactor by the sequential batch feeding method, the residence time of the material is 5d, and the poultry manure inoculum (VS 底物 : VS 接种物 =3:1), adjust the pH to 11, run at 55°C for 10 days, and then use a high-speed centrifuge for solid-liquid separation. The collected liquid is rich in volatile organic acids, and the content of organic acids can reach 10g / L.

[0038] S3: Dry the solid part collected in step S2 to a constant weight in an oven at 105° C. to obtain the raw material to be pyrolyzed.

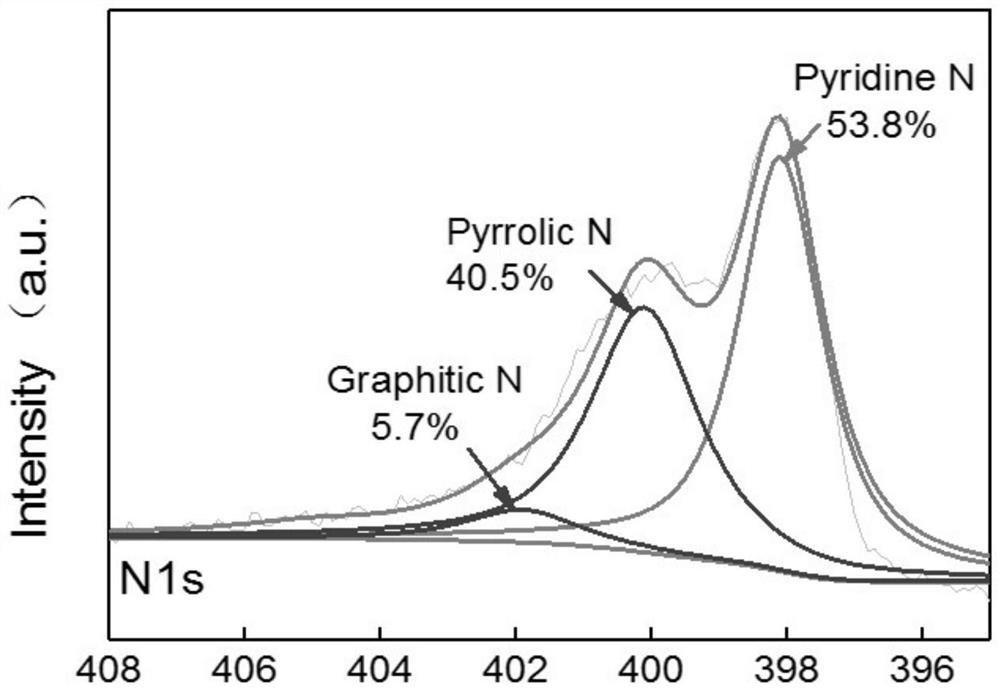

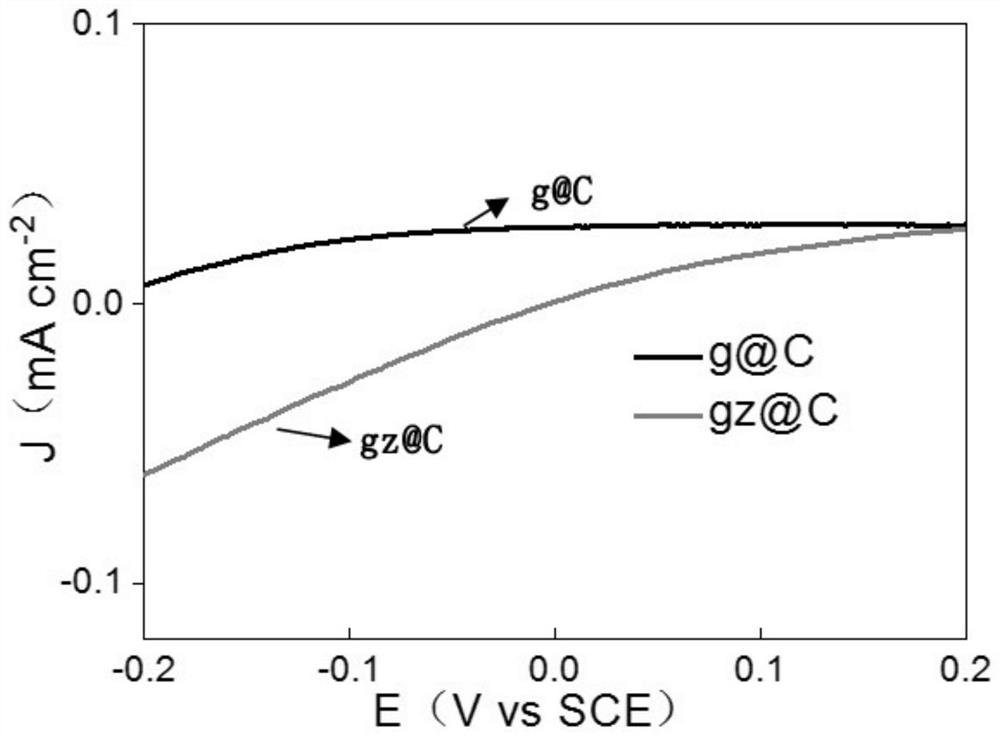

[0039] S4: Combine the raw material to be pyrolyzed obtained in step S3 with K 2 CO 3 ...

Embodiment 2

[0051] A method for co-producing acid and high-nitrogen porous carbon materials by using hybrid pennisetum, comprising the steps of:

[0052] S1: Pulverize Pennisetum hybrida, mix it with water at a solid-to-liquid ratio of 1:15, and perform pretreatment in a hydrothermal reactor at 180°C for 4 hours.

[0053] S2: The material after pretreatment in step S1 is transferred to the acid production reactor by the sequential batch feeding method, the residence time of the material is 5d, and the poultry manure inoculum (VS 底物 : VS 接种物 =3:1), adjust the pH to 10, run at 35°C for 4 days, and then use a high-speed centrifuge for solid-liquid separation. The collected liquid is rich in volatile organic acids, and the content of organic acids can reach 5g / L.

[0054] S3: Dry the solid part collected in step S2 to a constant weight in an oven at 105° C. to obtain the raw material to be pyrolyzed.

[0055] S4: Combine the raw material to be pyrolyzed obtained in step S3 with ZnCl 2 Mix ...

Embodiment 3

[0060] A method for using crop stalks to co-produce acid and high-nitrogen porous carbon materials, comprising the following steps:

[0061] S1: Crush the straw, mix it with water at a solid-to-liquid ratio of 1:20, and perform pretreatment in a hydrothermal reactor at 200°C for 6 hours.

[0062] S2: The material after pretreatment in step S1 is transferred to the acid production reactor by the sequential batch feeding method, the residence time of the material is 5d, and the poultry manure inoculum (VS 底物 : VS 接种物 =3:1), adjust the pH to 10, run at 35°C for 6 days, and then use a high-speed centrifuge for solid-liquid separation. The collected liquid is rich in volatile organic acids, and the content of organic acids can reach 6g / L.

[0063] S3: Dry the solid part collected in step S2 to a constant weight in an oven at 105° C. to obtain the raw material to be pyrolyzed.

[0064] S4: Combine the raw material to be pyrolyzed obtained in step S3 with K 2 CO 3 Mix thoroughly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com