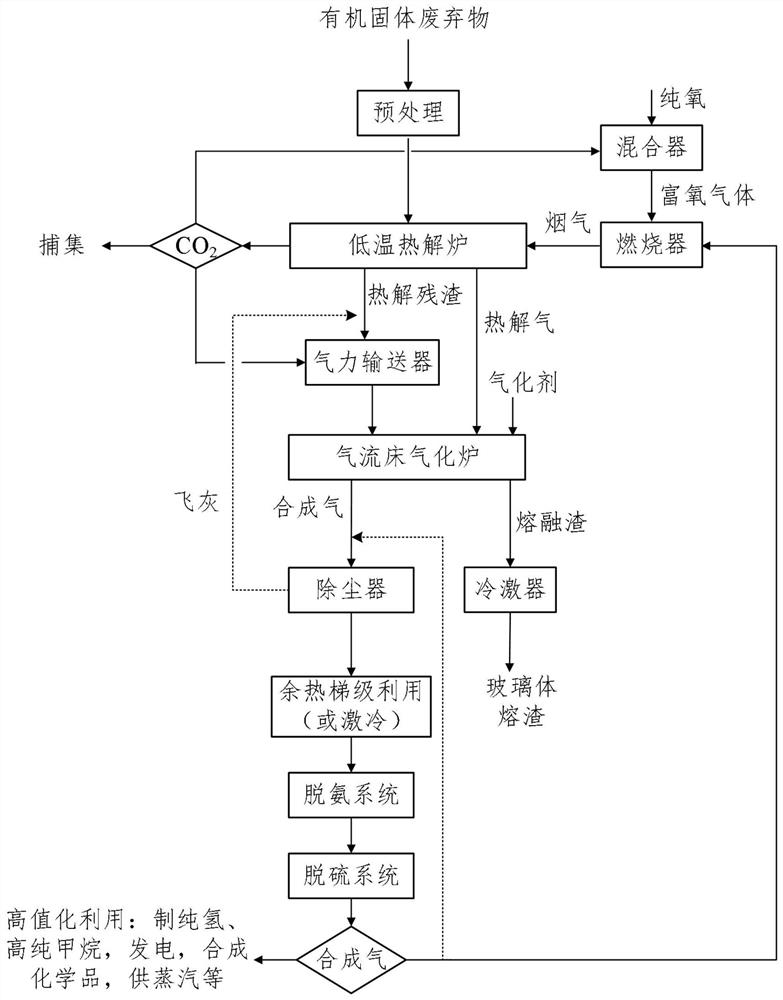

Organic solid waste composite thermochemical treatment and utilization method

A composite thermochemical and organic solid technology, applied in gasification process, production of combustible gas, granular/powder fuel gasification, etc., can solve the problems of low public acceptance, high energy consumption and cost, high disposal difficulty, and achieve The effect of improving gasification reaction efficiency, efficient capture and utilization, and improving system safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present invention provides a composite thermochemical disposal and resource utilization process of organic solid waste (steel mill sludge). The specific steps are as follows:

[0031] 1) After the steel mill sludge is pretreated by pressure filtration and drying, the calorific value of the raw material is 1800kcal / kg, and the moisture content is 40%. The pretreated material is transported to the pyrolysis reactor at 300°C and 20kPa pyrolysis in the middle to obtain pyrolysis residue and pyrolysis gas.

[0032] 2) Pyrolysis residue, pyrolysis gas and gasification agent (pure oxygen) enter the high-temperature entrained bed gasification furnace through the nozzle, and perform high-temperature gasification and melting reaction in the gasification furnace. The temperature of the high-temperature gasification and melting area in the furnace is 1400~ 1600°C, the gasification pressure is 20kPa, producing high temperature syngas and slag.

[0033] 3) The main components of...

Embodiment 2

[0036] The invention provides a composite thermochemical disposal and resource utilization process of organic solid waste (landfill waste), the specific steps are as follows:

[0037] 1) After sorting, crushing, pressure filtration, and drying pretreatment of landfill waste, the calorific value of the raw material is 1200kcal / kg, and the moisture content is 20%. The pretreated material is transported to 500°C and 500kPa pyrolysis in the pyrolysis reactor to obtain pyrolysis residue and pyrolysis gas.

[0038] 2) The pyrolysis residue is mixed with biomass powder, and enters the high-temperature entrained-bed gasification furnace through the nozzle with pyrolysis gas and gasification agent (pure oxygen and water vapor), and performs high-temperature gasification and melting reaction in the gasification furnace. The temperature in the high-temperature gasification and melting zone is controlled at 1400-1600°C, and the gasification pressure is 500kPa to produce high-temperature syn...

Embodiment 3

[0042] The present invention provides a compound thermochemical treatment and resource utilization process of organic solid waste (refining sludge). The specific steps are as follows:

[0043] 1) After the refinery sludge is pretreated by pressure filtration and drying, the calorific value of the raw material is 5000kcal / kg, and the moisture content is 40%. The pretreated material is transported to the pyrolysis reactor at 400°C and 100kPa pyrolysis in the middle to obtain pyrolysis residue and pyrolysis gas.

[0044] 2) Pyrolysis residue, pyrolysis gas mixed with natural gas, and gasification agent (pure oxygen) enter the high-temperature entrained-bed gasification furnace through the nozzle, and undergo high-temperature gasification and melting reaction in the gasification furnace. The temperature of the high-temperature gasification and melting zone in the furnace is The temperature is 1600~1800°C, the gasification pressure is 100kPa, and high-temperature syngas and slag ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com