Slurry titanium dioxide and preparation method thereof

A technology of slurry and titanium dioxide, which is applied in the field of titanium dioxide, can solve the problems of poor storage stability of slurry titanium dioxide, impact on the application performance of titanium dioxide slurry, and influence on the dispersion of slurry titanium dioxide, so as to improve dispersion stability and Storage stability, reducing grinding and dispersing costs, and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

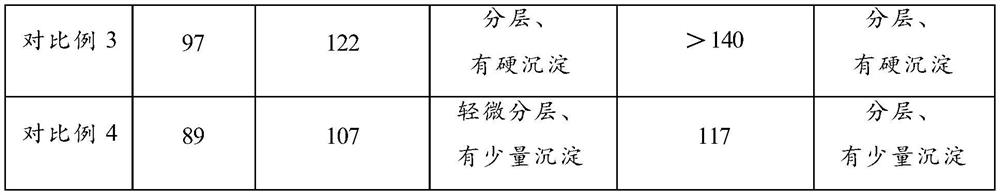

Examples

Embodiment 1

[0064] The slurry titanium dioxide provided in this embodiment includes titanium dioxide and a dispersant coated with a first layer of coating and a second coating in sequence from the inside to the outside, wherein the film layer of the first coating is mainly composed of nano-sized zirconia Composed of zirconia and zirconia, the film layer of the second coating is mainly composed of nano-alumina and aluminum oxide.

[0065] The preparation method of the slurry titanium dioxide provided in this embodiment comprises the following steps:

[0066] (1) to ZrO 2 Add nano-zirconia with a particle size of 30 to 50 nm in the zirconium oxychloride solution with a mass fraction of 35.5%, and mix uniformly to obtain a mixed solution of nano-zirconia and zirconium oxychloride; 2 Calculated, the concentration of zirconium oxychloride solution is 100g / L; 2 Calculate the mass of zirconium oxychloride × 100% = 0.5%;

[0067] to Al 2 o 3 Add nano-alumina with a particle size of 30 to 60 ...

Embodiment 2

[0076] The slurry titanium dioxide provided in this embodiment includes titanium dioxide and a dispersant coated with a first layer of coating and a second layer of coating in sequence from the inside to the outside, wherein the film layer of the first layer of coating is mainly composed of nano-silica And silicon oxide, the film layer of the second coating is mainly composed of nano-alumina and aluminum oxide.

[0077] The preparation method of the slurry titanium dioxide provided in this embodiment comprises the following steps:

[0078] (1) to SiO 2 Add nano-silicon oxide with a particle size of 20 to 50 nm into the sodium silicate solution with a mass fraction of 25%, and mix uniformly to obtain a mixed solution of nano-silicon oxide and sodium silicate; 2 Calculated, the concentration of sodium silicate solution is 100g / L; 2 Calculate the mass of sodium silicate × 100% = 1.2%;

[0079] to Al 2 o3 Add nano-alumina with a particle size of 30 to 60 nm in the sodium metaa...

Embodiment 3

[0089] The slurry titanium dioxide provided in this embodiment includes titanium dioxide and a dispersant coated with a first layer of coating and a second coating in sequence from the inside to the outside, wherein the film layer of the first coating is mainly composed of nano-sized zirconia Composed of zirconia and zirconia, the film layer of the second coating is mainly composed of nano-alumina and aluminum oxide.

[0090] The preparation method of the slurry titanium dioxide provided in this embodiment comprises the following steps:

[0091] (1) to ZrO 2 Add nano-zirconia with a particle size of 30 to 50 nm in the zirconium oxychloride solution with a mass fraction of 35.5%, and mix uniformly to obtain a mixed solution of nano-zirconia and zirconium oxychloride; 2 Calculated, the concentration of zirconium oxychloride solution is 100g / L; 2 Calculate the mass of zirconium oxychloride × 100% = 0.8%;

[0092] to Al 2 o 3 Add nano-alumina with a particle size of 30 to 60 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com