Building waterproof self-repairing material and preparation method thereof

A self-healing material and building waterproofing technology, applied in the field of building materials, can solve problems such as being unsuitable for the long-term development of the building waterproofing industry, poor compatibility of concrete substrates, and poor environmental performance, achieving good fluidity, enhanced mechanical properties and durability. , Good construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

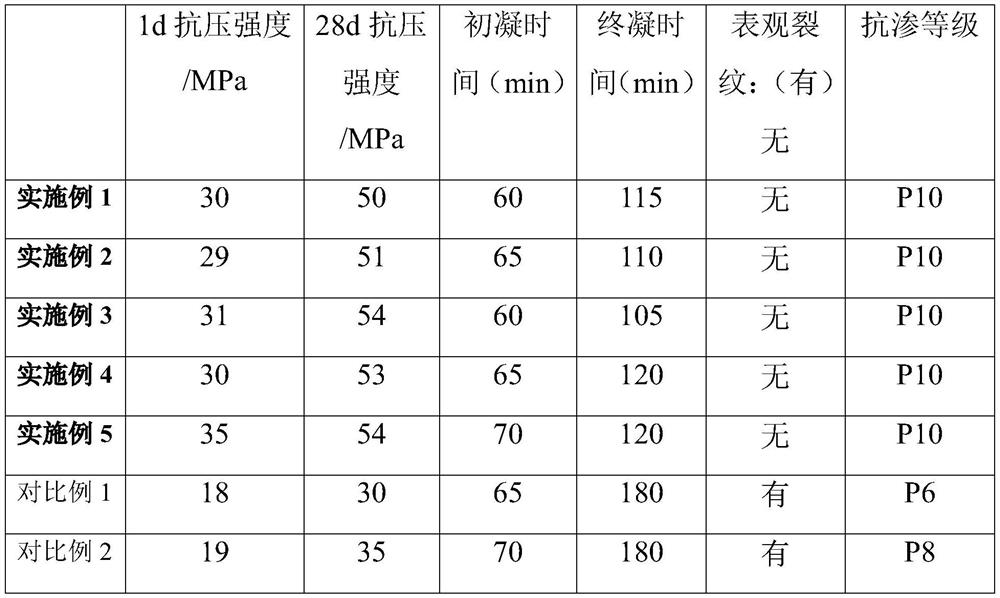

Examples

preparation example Construction

[0041] The present invention also provides a preparation method applied to the building waterproof self-repairing material described in any of the above embodiments, comprising the following steps:

[0042] S1. The ingredients are as follows (g / L): starch: 10, glucose: 10, beef extract: 5, KNO3: 0.5, NaCl: 0.5, KH2PO4: 2, MgSO4: 0.5, FeSO4·7H2O: 0.005, pH 7, and Mix 500ml of sterile water and put it in a shaker at 30°C for 5 days to shake for 5 days to obtain a microbial culture medium, a modified CAZPECK DOX-medium medium;

[0043] S2. Stir the raw materials according to the above mass percentages in a mixer for 1 to 2 minutes, and mix them uniformly to obtain a dry blend;

[0044] S3. Add water, water reducing agent, flocculant, antifreeze agent, air-entraining agent and alkaline activator to the dry mixture prepared in step S2, and mix and stir for 2 to 5 minutes until the mixture has good fluidity. Prepare the slurry;

[0045] S4, adding the microorganisms in the culture...

Embodiment 1

[0050] Including the following raw materials according to mass percentage: 10% cement, 15% silica fume, 10% fly ash, 15% slag, 1% nano silicon dioxide, 1% nano clay, 1% clay regulator, 1% nano cellulose, Hydrogel 2%, porogen 0.3%, polycarboxylate superplasticizer 0.3%, flocculant 0.3%, air-entraining agent 0.3%, alkaline activator 3%, microorganism (fungi, bacteria, actinomycetes) 0.01 %((g / L): starch: 10, glucose: 10, beef extract: 5, KNO3: 0.5, NaCl: 0.5, KH2PO4: 2, MgSO4: 0.5, FeSO4 7H2O: 0.005)), the balance is water, The sum of the mass percentages of the above components is 100%.

[0051] Preparation process steps:

[0052] S1. The ingredients are as follows (g / L): starch: 10, glucose: 10, beef extract: 5, KNO3: 0.5, NaCl: 0.5, KH2PO4: 2, MgSO4: 0.5, FeSO4·7H2O: 0.005, pH 7, and 500ml of sterile water was mixed and placed in a shaker at 30°C for 5 days. The medium commonly used for making microorganisms - modified CAZPECK DOX-medium medium.

[0053] S2. Stir cement, ...

Embodiment 2

[0059] A building waterproof self-repairing material and a preparation method thereof, comprising the following raw materials in terms of mass percentages:

[0060] 12% cement, 17% silica fume, 12% fly ash, 17% slag, 2% nano-silica, 2% nano-clay, 2% clay regulator, 2% nano-cellulose, 3% hydrogel. Pore agent 0.4%, polycarboxylate superplasticizer 0.4%, flocculant 0.4%, air-entraining agent 0.4%, alkaline activator 4%, microorganism (fungi, bacteria, actinomycetes) 0.01%-0.03% ((g / L): starch: 10, glucose: 10, beef extract: 5, KNO3: 0.5, NaCl: 0.5, KH2PO4: 2, MgSO4: 0.5, FeSO4 7H2O: 0.005)), the rest is water, the above components The sum of the mass percentages is 100%.

[0061] The preparation steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com